3

Precautions for field assembly

Precautions for field assembly

1. Selection of work place

1) When selecting a work place, consider the following.

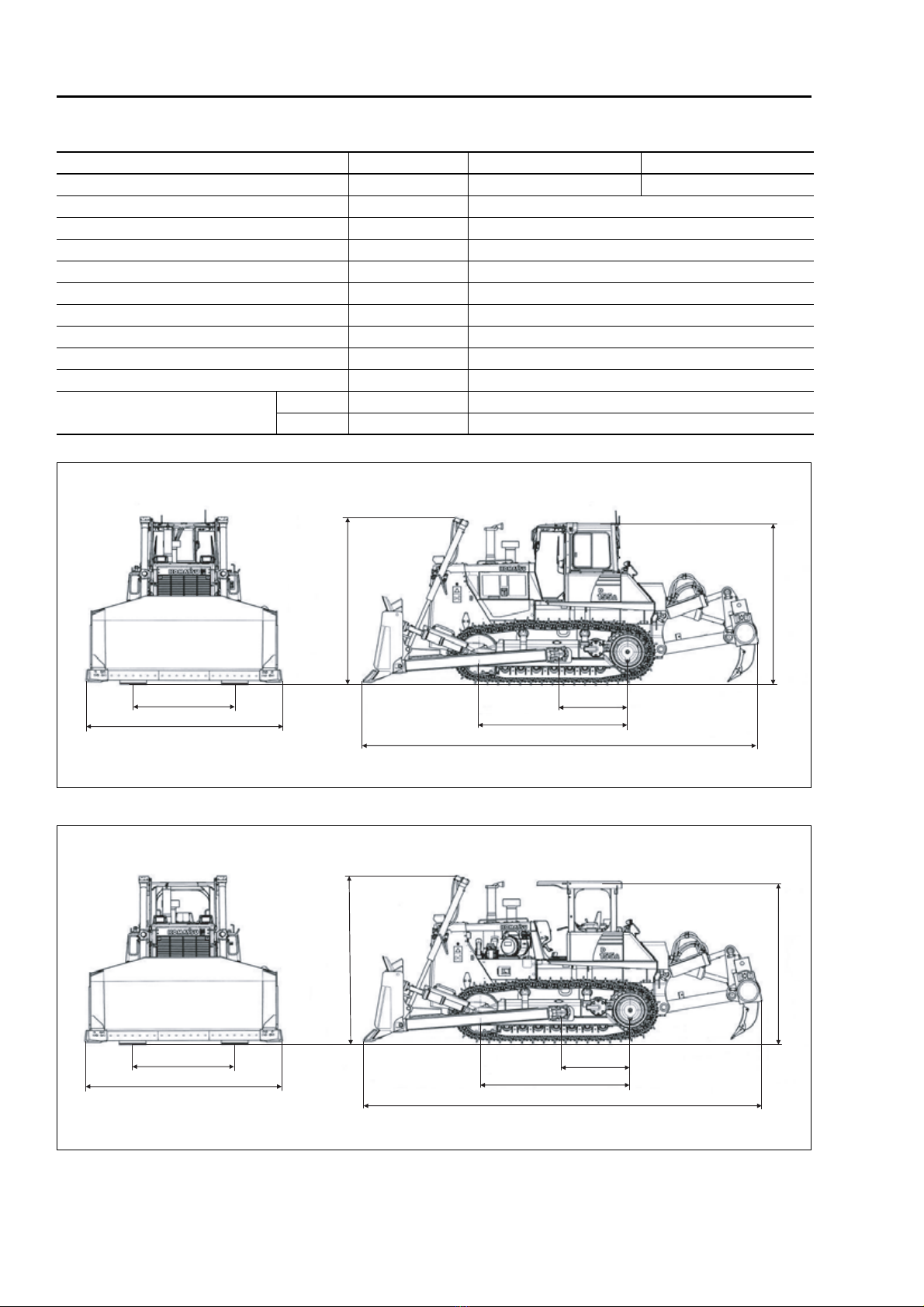

• Is the work place sufficiently wide for loading and unloading the machine? (See the kit layout draw-

ing.)

• Is the ground sufficiently hard? (The machine and crane truck must not sink into the ground.)

• Is the ground flat? (The ground surface must not be uneven or sloping.)

• Is the road to inlet/outlet of the work place sufficient for turning the trailer and crane truck?

2) Take care extremely that dirt or water will not enter the hydraulic circuit while it is assembled.

3) Avoid working outdoors while strong wind is blowing or it is raining.

4) Take measures to protect the machine from sand, dirt and rainwater while the work is stopped.

2. How to do work

The work supervisor or the work leader should not do the work while reading this manual but should read

and understand this manual thoroughly and then start the work.

In particular, write the "Precautions" for each work process in a sheet to explain or stick that sheet to the

work place so that all the workers will observe the precautions.

3. Preparation and check of protective gear, slings and tools

The work supervisor or the work leader must perform the following checks about protective gear, slings and

tools.

1) Are all the workers wearing helmets and other protective gear which they are obliged to wear?

If special protective gear is necessary, check that it is prepared and can be used without problem.

2) Are all the slings and tools prepared? Check in advance that they are ready to be used without prob-

lem. In particular, check wooden blocks for internal decay and cracking.

4. kCheck during actual work

The work supervisor or the work leader must check the following items constantly and make all the workers

observe them.

1) Are the parking brakes of the trailer and crane truck applied securely and are their wheels locked with

chocks during work? Are outriggers, if installed, used securely?

2) Are the temperature and pressure of the engine, hydraulic oil, coolant, etc. lowered sufficiently during

work?

3) Is horn or another signal is made to warn around when the engine is started? In addition, is it checked

that work equipment control lever and other control levers are in neutral and the fuel control dial (or fuel

control lever) is in the low idle position?

4) Is the balance of the slung item checked extremely during sling work with the crane?

5) Is entry prohibition for outsiders to the work place observed?

5. The work supervisor or the work leader is required to hold a meeting with all the workers at the beginning of

every morning and explain the work plan of the day to them and give them instructions to observe the safe

work.