Novar ETM-2040 User manual

ETM-2040 Installation

Instructions

DOC. #560075000 2/12/01 PRINTED IN U.S.A.

FCC InformationThis device complies with Part 15 of the FCC rules. Operation is subject to the following

two conditions: (1) This device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause undesired

operation.

NOTE!This equipment has been tested and found to comply with the limits for

a Class B digital device pursuant to Part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is

likely to cause harmful interference, in which case the user will be

required to correct the interference at his own expense.

CAUTION!Any changes or modifications not expressly approved by Novar

Controls Corporation could void your authority to operate this

equipment.

Industry CanadaThis digital apparatus does not exceed the Class B limits for radio noise emissions from

digital apparatus set out in the interference-causing equipment standard entitled Digital

Apparatus, ICES-003, of Industry Canada.

Cet appareil numérique respecte les limites de bruits radioélectriques applicables aux

appareils numériques de Classe B préscrites dans la norme sur le matériel brouiller:

Appareils Numériques, NMB-003, édictée par l’Industrie Canada.

DisclaimerLOGIC ONE ®is a registered trademark of Novar Controls Corporation.

The material in this manual is for information purposes only. The contents and the

product it describes are subject to change without notice. Novar Controls Corporation

makes no representations or warranties with respect to this manual.

In no event shall Novar Controls Corporation be liable for technical or editorial omissions

or mistakes in this manual, nor shall it be liable for any damages, direct or incidental,

arising out of or related to the use of this manual.

Copyright © 2001 by Novar Controls Corporation. All rights reserved.

No part of this manual may be reproduced in any form or by any means

without prior written permission from Novar Controls Corporation.

Novar Controls Corporation

3333 Copley Road, Copley, OH 44321

Tel: (330) 670-1010 www.novarcontrols.com

Description

The Electronic Thermostat Modules (ETMs) are LOGIC ONE ®intelligent control

modules that can be distributed throughout a building to provide local direct digital

control of unitary, packaged, staged HVAC systems. The ETM-2040 is a wall-mount

module that must be mounted in the space being controlled because the sensor is

connected directly to the module. One additionalremote temperature sensor and a

digital dirty filter switch can be wired to the ETM-2040.

This document provides instructions for mounting the ETM baseplate, wiring the

module, setting the address, installing the electronics, and checking the

installation.

ETM-2040 Specifications

Power Requirements

Voltage:24 VDC, Class 2

Current:120 mA

Operating Environment

Temperature:32° to 122°F (0° to 50°C)

Humidity:0 to 95% Relative, noncondensing

Physical Dimensions

Height:4.875 inches

Width:7.093 inches

Depth:1.75 inches

Weight:1 lb

Precautions

Take the following precautions during installation:

§Observe national and local electrical codes.

§Observe voltage and current limits marked on the module.

§Do not exceed 24-VAC at 1 ampere on any load.

Mounting the ETM-2040

Baseplate

The ETM-2040 baseplate should be mounted horizontally, approximately 5 feet

above the floor, in an area that is free from drafts and sudden changes in

temperature. The baseplate may be mounted to an electrical junction box or

directly to a wall or panel.

The baseplate is shipped with a hardware kit that contains four screws, four

hollow-wall anchors, one module address label, and 15 wire nuts.

NOTE!Use the hollow-wall anchors when mounting to paneling

or drywall. When mounting to a cement block or brick

wall, use a 3/8-inch to ½-inch layer of insulation between

the wall and the baseplate.

DOC. #560075000 2/12/011

ETM-2040 Installation Instructions

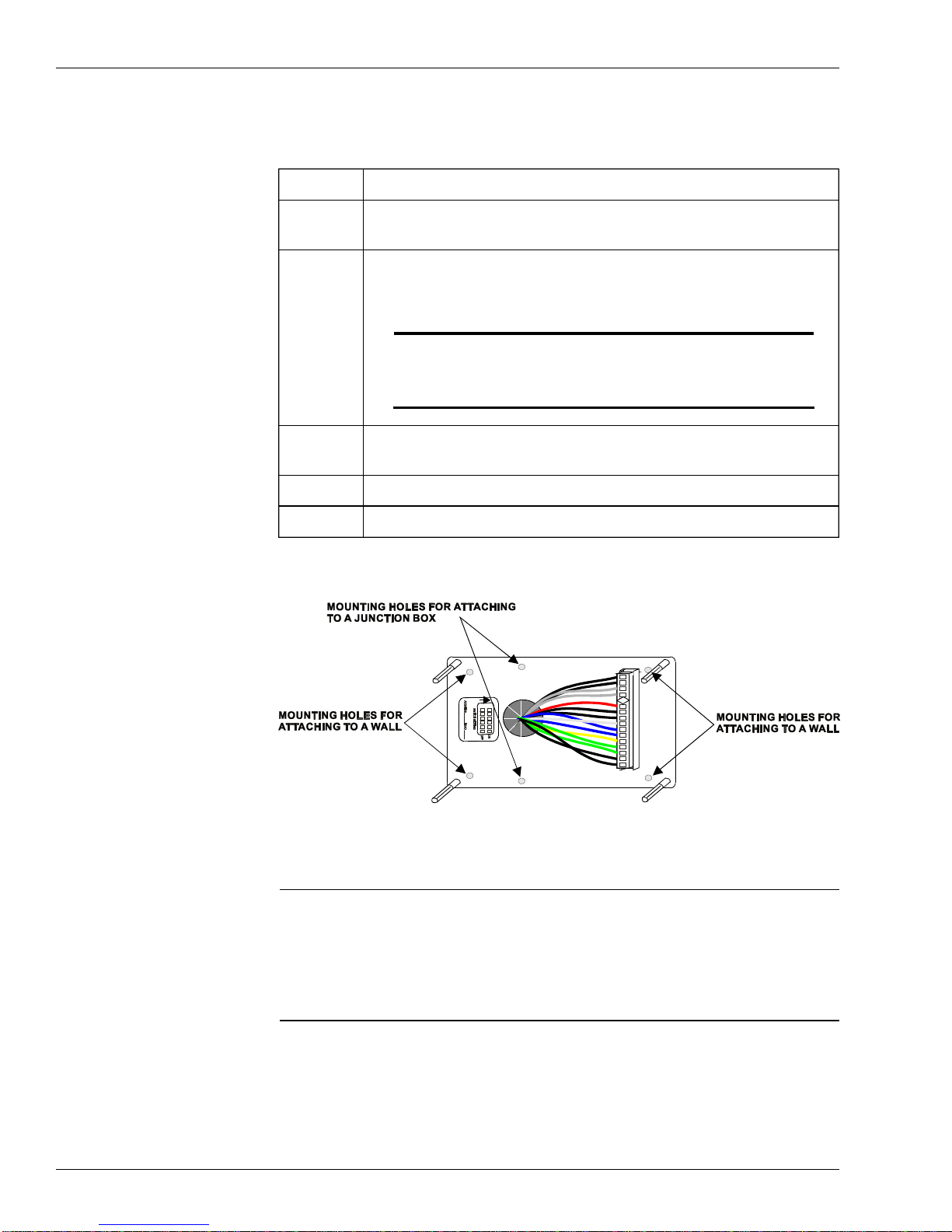

Use the following procedure and refer to Figure 1, as necessary to mount the

baseplate.

StepProcedure

1Turn off all power to the HVAC equipment before mounting the

baseplate.

2Position the baseplate against the mounting surface and mark the

surface to show the location of the four screw holes in the corners

of the baseplate.

NOTE!To mount the baseplate to a junction box, use the

two holes located directly above and below the

large hole through which the wires pass.

3Drill holes in the locations marked on the mounting surface and

insert hollow-wall anchors (and insulation, if necessary).

4Position the baseplate over the screws.

5Tighten the screws to secure the baseplate.

Supplying the ETM-2040

with Power

Connect the ETM-2040 to a suitable 24-VDC power supply. Connect the

positive (+) and negative (–) power terminals to the appropriate wire as indicated

in Table 1.

2DOC. #560075000 2/12/01

ETM-2040 Installation Instructions

Figure 1.Mounting the baseplate

Wiring the ETM-2040

Control Outputs

Use the wire nuts provided and the wiring scheme outlined in Table 1 to connect

the ETM-2040 baseplate wires to the HVAC control/interface equipment.

CAUTION!Make sure the wiring is connected properly to

prevent permanent damage to the system.

Table 1. ETM-2040 Wiring Scheme

PIN NUMBER/COLORFUNCTION

1 White/BlueHeat Stage 2

2 WhiteHeat Stage 1

3 White/BlackModule Communication (–)

4 White/RedModule Communication (+)

5 Dark BlueHeat/Cool Return (Transformer Power)

6 YellowCool Stage 1

7 OrangeCool Stage 2

8 White/Black/GreenModule Power (–)

9 White/Black/RedModule Power (+), +24-VDC

10 Light BlueHeating Stage 3 or Dampers

11 GreenFan

12 BrownFan Status Input

13 White/BrownFilter Status Input

14 Polarizing Key

15 BlackStatus Return

16 BlackStatus Return

17 BlackModule Communication (Shield)

18 VioletTemperature Sensor (+)

19 GrayTemperature Sensor (–)

DOC. #560075000 2/12/013

ETM-2040 Installation Instructions

Temperature Sensor

The distance between the ETM and the temperature sensor can be up to 1000

feet. Refer to the sensor’s installation instructions for mounting and complete

wiring details.

StepProcedure

1Mount the remote temperature sensor in the zone being controlled

or in the supply air of the HVAC unit.

2Run a shielded 2-conductor cable (Belden 8761, Novar

WIR-1010, or equivalent) from the sensor to the baseplate.

3Connect the plus (+) lead to the violet wire.

4Connect the minus (–) lead to the gray wire at the ETM-2040.

Fan Status

Use a shielded 2-conductor cable (Belden 8761, Novar WIR-1010, or equivalent)

to connect the fan status switch to the ETM.

StepProcedure

1Connect one lead from the fan status switch to the ETM’s brown

wire.

2Connect the other lead from the fan status switch to one of the

ETM’s black wires (see Table 1, Status Return).

The fan status switch contact is open when the fan is off and closed when the fan

is on.

Dirty Filter Switch

Use a shielded 2-conductor cable (Belden 8761, Novar WIR-1010, or equivalent)

to connect the filter status switch to the ETM.

StepProcedure

1Connect one lead from the filter status switch to the ETM’s

white/brown wire.

2Connect the other lead from the filter status switch to one of the

ETM’s black wires (see Table 1, Status Return).

The filter status switch contact is closed when the filter is dirty.

4DOC. #560075000 2/12/01

ETM-2040 Installation Instructions

Communications Network

Use a shielded 2-conductor cable (Belden 8761, Novar WIR-1010, or equivalent)

to connect communications between the ETM and the network communication

terminals of the executive module. Use the following procedure to make the

connections at the ETM.

StepProcedure

1Connect the plus (+) lead to the white/red wire.

2Connect the minus (–) lead to the white/black wire.

3Connect the shield to the black wire (see Table 1, Module

Communication Shield).

Testing the Wiring

Before installing the ETM-2040 electronics module, use an ETM Interface

Analyzer and the ETM-2020 adapter cable to test the baseplate for correct

wiring. The analyzer tests for module power and allows manual cycling of the

ETM outputs. Instructions are provided with the analyzer and the adapter cable.

Installing the ETM-2040

Electronics

NOTE!Before the electronics are installed, make sure that the

baseplate has been properly installed.

A hardware kit to be used during installation is shipped with the electronics. It

contains four screws and a hex key.

Setting the Module’s Address

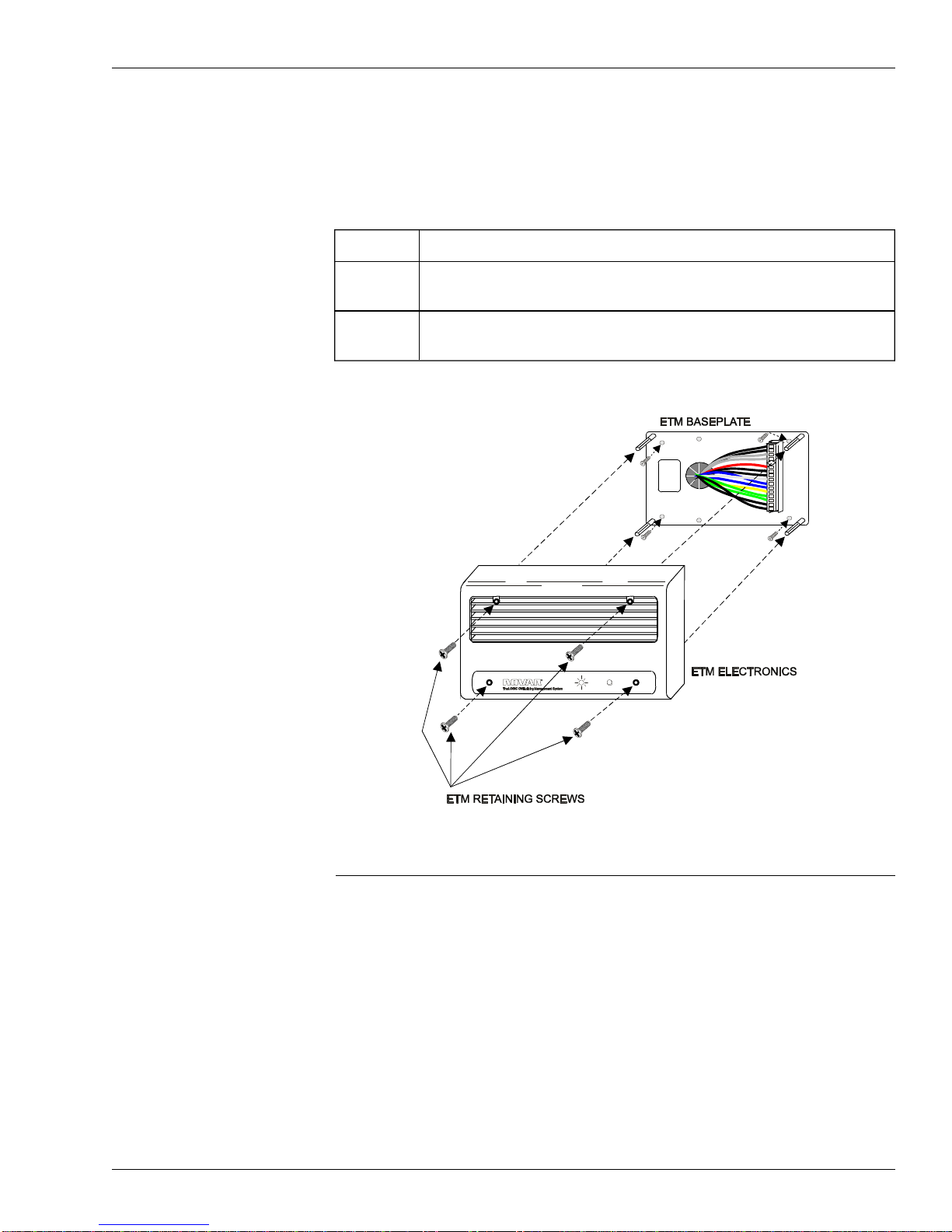

Locate the address switches on the rear of the module (see Figure 2). Each

module requires a unique address for the executive module to identify it.

Addresses are assigned during system programming. Use the system

configuration to find the address of the ETM being installed.

DOC. #560075000 2/12/015

ETM-2040 Installation Instructions

Figure 2.ETM address switch and connector

Set the switches on the back of the electronics with the correct address from 00 to

63 (see Figure 3).

NOTE!Address 00 may notbe used by the ETM when operating

on an EC. (The IOM section of the EC uses address 00).

Record the settings on the module address switch label on the back of the ETM

electronics and on the label provided with the ETM baseplate hardware kit.

Apply the baseplate label to the ETM baseplate as shown in Figure 2.

The EP/2 executive module is designed to accept module addresses from 00 to

127 for any type of LOGIC ONE module. The EP/2 would require a Network

Expander to communicate with addresses 64 through 127. Only unitary

controllers can be connected to the Network Expander. Addresses 64 through

127 are set using the same sequence of settings shown in Figure 3, beginning

with address setting 64 being the same as address setting 00, etc. (The Network

Expander Module Installation Instructions [Doc. #560092000] provide more

information about setting the addresses from 64 through 127.) When connecting

additional modules to the EP/2, do not exceed the their 128-input or 128-output

limits.

6DOC. #560075000 2/12/01

ETM-2040 Installation Instructions

Figure 3.Setting the module address

Mounting the ETM

Electronics

Use the following procedure and refer to Figure 4 to mount the ETM electronics

on the baseplate. Make sure the connector on the rear of the ETM electronics fits

properly into the pigtail wiring connector on the baseplate.

StepProcedure

1Align the module over the mounting posts and press onto the

baseplate connector as shown in Figure 4.

2Use the screws and hex key provided in the hardware kit to secure

the module to the posts.

Checking Installation

Turn on power to the ETM-2040. Make sure that power to the HVAC equipment

and its control circuitry is on. If the executiv e module is operating properly, the

ETM begins to control the HVAC equipment in about 3 minutes (after

performing a self-diagnostic check and establishing communications with the

executive module).

§Output Status Indicators

There are six output status indicators (inside the ETM case and visible through

the front grill) that show the status of each output. The indicator is lit when

the corresponding output is on.

DOC. #560075000 2/12/017

ETM-2040 Installation Instructions

Figure 4.ETM electronics installation

§Override Switch Input

The ETM-2040 has a built-in timed override switch. To test the switch for

proper function, press the switch when the schedule status indicator is off (if

set to “active” in the software). The schedule status indicator exhibits a steady

flash that stops when the override period ends. On a call for heating or

cooling, the ETM’s output indicators should show a change in status.

To cancel the timed override, press the button a second time. The schedule

status indicator stops flashing when the timed override is canceled.

§Schedule Status Indicator

Observe the flashing pattern of the schedule status indicator to verify proper

communications between the ETM and the executive module.

—The schedule status indicator should be on during scheduled on periods.

—The schedule status indicator should be off during scheduled off periods.

It flashes on or off regularly when communicating with the executive module,

depending upon the schedule status (off or on). When a scheduled timed

override has been implemented, the schedule status indicator flashes steadily

and stops when the override period ends. The steady flash is broken when the

ETM is communicating with the executive module.

§Checking from the EP/2 or EC

If any faults or malfunctions still exist, they are picked up by the executive

module and announced by alarm messages.

Monitor the executive module display during the test procedures. The ETM’s

setpoints can be altered from the executive module keypad and the status

display monitored for proper equipment response from the keypad.

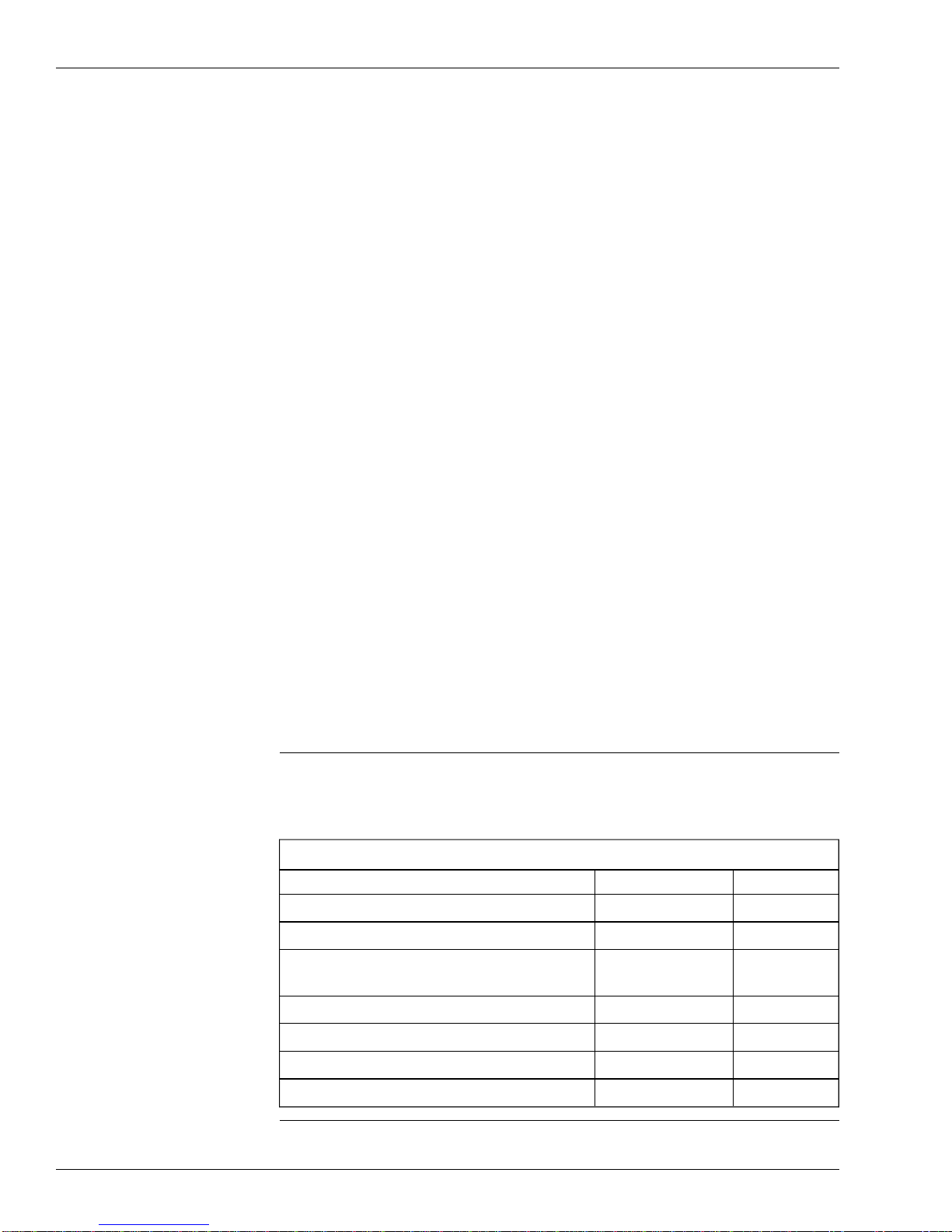

Model and Part Numbers

Use the part numbers provided in Table 2 to order the necessary Novar parts.

Table 2. Novar ETM-2040 Model Numbers

PRODUCTMODEL NO.PART NO.

ETM-2040 BaseplateETM-2040-BPL705100000

ETM-2040 Electronics ETM-2040729041000

Two-conductor, shielded cable (Belden

8761equivalent)WIR-1010709001000

Module Interface AnalyzerMOD-EIA706000000

Adapter CableEIAC706065000

Wall-Mount Temperature SensorWTS-10712003000

Futura Temperature SensorFTS-1732203000

8DOC. #560075000 2/12/01

ETM-2040 Installation Instructions

Table of contents

Other Novar Control Unit manuals

Popular Control Unit manuals by other brands

EDS

EDS SPM-010 user guide

PRESONUS

PRESONUS CENTRAL STATION user manual

AVer

AVer NV series user manual

National Instruments

National Instruments 9221 Getting started guide

Texas Instruments

Texas Instruments LM5122EVM-2PH user guide

Deep Sea Electronics Plc

Deep Sea Electronics Plc DSE6120 MKII Operator's manual