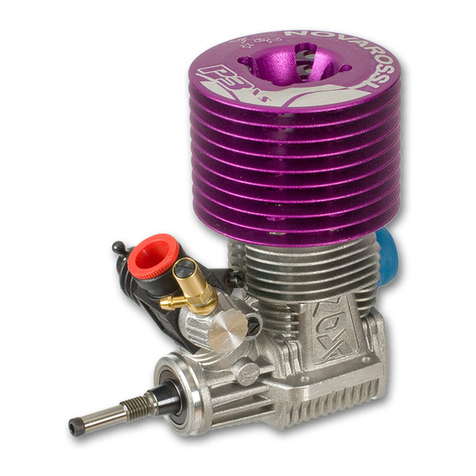

Carburettor setting starting tuning

www.novarossi.it | store.novarossi.it

The engines must not be modified. All the modifications will make the engine unstable in tuning and weaker in operation. Novarossi

World s.r.l. will not be responsible for any modification on its engines.

1. SAFETY RULES

This product is not a toy but a competition engine. It can be dangerous and it can cause damages if these safety rules are not followed

and the instructions specified in this workbook are not followed. In particular:

- This engine cannot be used under 14 years of age;

- The engine must not be started before having fixed it on the model with 4 screws as explained on the model's manufacturer hand book;

- Do not manipulate or modify the engine in order to avoid dangerous situations. Use it only with suitable pipes. Novarossi World S.r.l. will

not guarantee the safety level of operating certified by the mark if any modification/manipulation is made on the engine itself.

- Only high quality radio controls and components must be used in order to assure a perfect and sure control of the model. In particular

the propeller must be of very high quality to minimize risk of breakage and unpredictable damages.

- The engine must be used only for model purposes.

For a complete list of safety rules see point “safety instructions”.

2. INTRODUCTION

These instructions have been prepared to:

- obtain the best performances from the engines guaranteeing them longer life;

- prevent mistaken maintenance before, during and after the use from generating damages to the engine;

- guarantee a high safety use level of the engine.

3. WARRANTY AND RESPONSABILITY

The warranty covers eventual manufacturing defects (material) but does not cover damages due to wrong or non correct use which does

not correspond to the specifications required at the order of the item. See indications given and limitations specified at point 9 of this

workbook. Any attempt to manipulate or any particular modification will cause the end of the warranty.

4. IDENTIFICATIONS OF THE ENGINE

In the engine box you will find these following documents:

- Identification sheet of the product, it includes batch number of the engine. This number is fundamental to track back the production

date of the engine and must always be transmitted in case of service's request;

- Exploded design of the engine and its carburettor: It includes an exploded design of all spare parts which are part of the engine and

carburettor and their referring part numbers or eventual optional parts.

- Factory carburettors settings Novarossi World reserves the right to modify products without notice.

5. CONNECTIONS / IGNITION STARTING AND STOP

5.1 CONNECTIONS.

Must be made properly following the instructions given by the model manufacturer:

1. Connect the manifold and the pipe to the tank;

2. Connect the fuel tube to the carburettor;

3. Connect the uniball of the carburettor to the servo control;

5.2 IGNITION AND STARTING.

1. Connect the glowplug to the 1.2-Max 1,5 Volt igniter;

2. Throttle by radio-control after you have opened the carburettor to a quarter of its total travel;

3. The ignition and starting system could be different: it could be like car or plane version.

5.3 STOP.

Stop the engine by closing the needle valve through the remote radio control or use a rag to cover the exhaust tip. Be careful!

The exhaust is extremely hot so be sure you are using a thick rag. Attention – Never stop the fly wheel with your hand.

6. RUNNING-IN

Novarossi World S.r.l. suggests to run in properly the engine in order to settle all its mechanical parts. The carburettor is set at the factory

and it only needs adjustments to control the base and full speed needle to get the best tuning. Fix the engine on the car and run it in at

low rpm for at least 30 minutes.

7. TYPE OF FUEL MUST BE USED.

You must use high quality fuel because good fuel grants good performances and long life to the engine. In our opinion the best lubricant

is castor oil (sale code 1N1) which prevents overheating and assists the lubrication of all moving parts such as bearings, crank pins, pistons

and sleeves. Small quantities of synthetic oils are allowed (sale code 1T2).

Fuel composition for running: 14% de gummed castor oil (first pressure acidity lower than 0.5) or 7% castor oil+7% synthetic oil+ 80% pure

methanol+ 6% nitro. Be aware that the compression ratio could vary accordingly to the engine’s operation level, to weather temperature

and pressure. Please follow these steps to optimize your engine in case of temperature fluctuations:

- In a case of a temperature increase, add 0.05 / 0.1 mm head shim.

- In case of a temperature reduction remove 0,05/0,1mm head shim.

Remember to compress your engine removing 0,05/0,1 mm head shims when the altitude increases compared to your normal operating

level. Fuel composition after the running: 25-30% nitro / 6% castor oil / 4% synthetic oil / 60-65% pure methanol.

8. BEST RUNNING-IN CONDITIONS FOR THE ENGINE

It is very important to wisely control the acceleration of the engine in order to make the pipe resonating as quietly as possible avoiding

useless skidding to the model; very often engines break during warm up due to sharp accelerations and to the driver’s frenzy. Sharp

acceleration causes the skidding of the balls of the ball bearing into their sliding guides and consequently wear.

WARNING

BEFORE USING THIS ENGINE PLEASE READ CAREFULLY THIS INSTRUCTION HANDBOOK

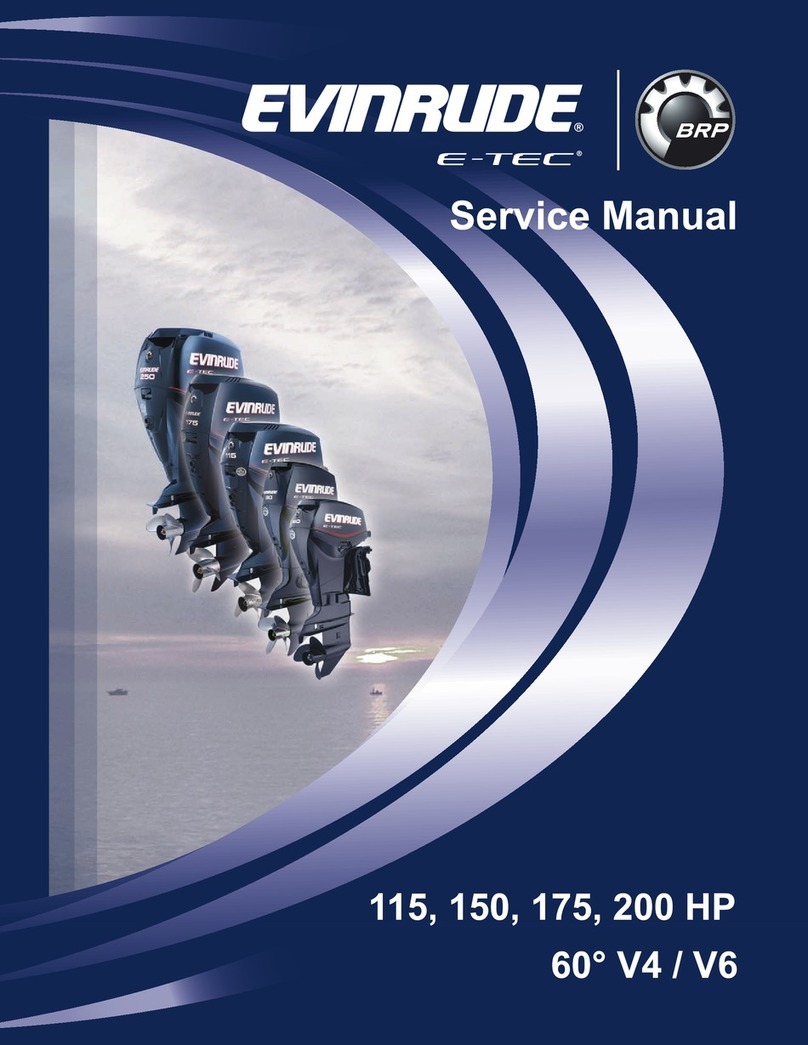

Unscrew the high speed needle “A” until it will stop, hold the metal lever

"C" as in the picture (totally opened). Once you reach the stop, screw for 7,5

turns.

Unscrew the low speed needle “B” until it will stop (totally opened). Once

you reach the stop, screw for 3,5 turns, holding the metal lever "D" .

Code: 75066 Code: 11000

A

C

Code: 75065

A

C

B

D

Code: 75065 / 75066Code: 24027

Screw clockwise the high speed needle “A” until it will stop. Once you

reach the stop, unscrew counterclockwise for 3,5 turns.

Screw clockwise the low speed needle “B” until it will stop while

keeping the carburetor barrel fully open. Then unscrew for 5turns

.

0.5 mm

B

C

A

The idle screw “C” is used to set the

mechanical minimum. Pushing the

barrel completely to the end in the

arrow direction, it needs to set the

screw to obtain an opening of about

0,5mm (see the picture). Before to do

this set we suggest to remove the

Venturi

.

N.B. : the tuning can vary depending on the type of

carburetor, track typology and driving style.

D

The screw “D” is the medium speed needle, used for a finer

carburetor tuning. To restore it at the factory setting, you

have to clockwise it until the stop and unscrew

of 1 turn and ¼

.

VERSIONS

Displacement:

R.P.M. Max Power:

Bore x stroke:

Crankshaft:

Glow plug:

Carburettor:

Weight:

3,49 cc

41.800

15,88 x 17,60 mm

14,5mm - Tuned - Turbo - DLC

C6TF

Aluminium - 9mm - 3 needles

265 g (without carb.)

Mephisto.21MH: Rear bearing with ceramic balls

Front bearing with steel balls

Mephisto.21MA: Rear and front steel balls bearing

Available with carburettors Code 24027 / 75065 / 75066 + 11000

MEPHISTO.21 MARINE

Marine Engine - extra long stroke - 9 ports

FUEL TYPE: 25% NITRO

TECH SPECS

RECOMMENDED EXHAUST

CARBURETTORS

TUNED PIPE:

MANIFOLDS:

Cod. 50042 / 50050 / 50054

Cod. 40042 / 40043 / 40045