NovaTec GSL Series User manual

USER GUIDE

MODELS:

>GSL-12

>GSL-19

Patent # 8,753,432 and 8,070,844

Vacuum Loaders

GSL Series

GSL-UG 17 June 2019

©2019 NOVATEC, Inc. All Rights Reserved

GSL-12

GSL-19

Oponal

machine mount

assembly

Remote

pendant control

In the space provided below you should record the model and serial

number(s) of your equipment and the date the equipment was received.

In the event you would need aermarket assistance our parts and ser-

vice department uses this informaon, along with the manual number, to

provide help for the specic equipment installed.

Please keep this instrucon manual, any relevant addendums, engineer-

ing prints and parts lists together for accurate documentaon of your

equipment.

NOTES

User Manual: GSL-UG 17 June 2019

Serial Number(s):

Model Numbers:

DISCLAIMER: NOVATEC, Inc., shall not be liable for errors in this instrucon

manual. Informaon can change without noce. Novatec makes no warranty of

any kind concerning the informaon contained herein, including, but not limited

to the implied warranes of merchantability and tness for a parcular purpose.

©2019 NOVATEC, Inc. All Rights Reserved.

Table of Contents

1 SPECIFICATIONS 4

2 UNPACKING AND INSPECTION 5

3 INSTALLATION 6

3.1 GSL 6

3.2 GSL MACHINE MOUNT MODELS 8

4 OPERATION OVERVIEW 9

6 ADJUSTING THE LOADER CONTROL 10

6.1 Loading Control System Terminology 12

6.2 Proporoning Valve Use 13

7 INITIAL STARTUP 14

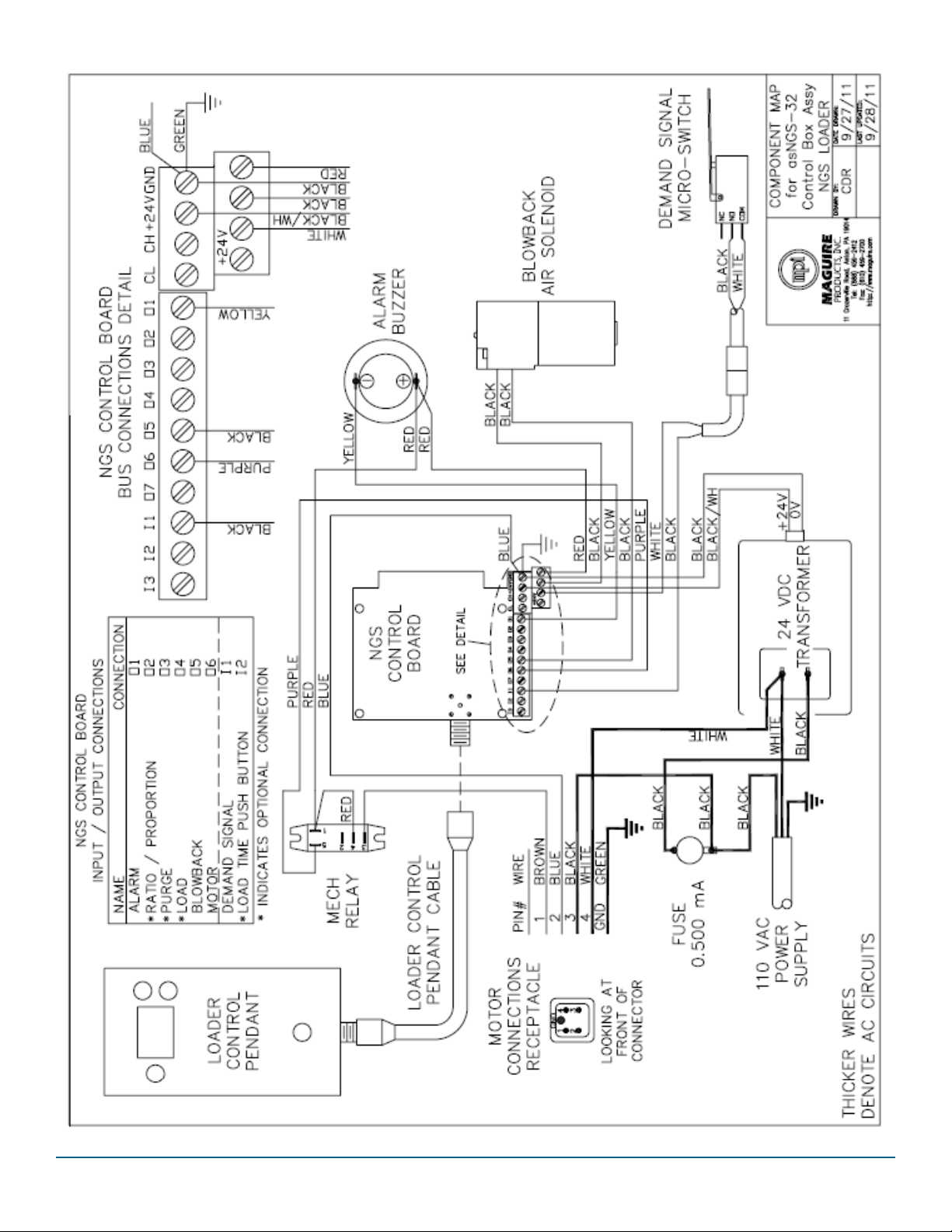

8 ELECTRICAL CONNECTIONS FOR LOADER OPTIONS 15

9 TROUBLESHOOTING 18

10 Warranty Periods: 19

4

1.0 PRINCIPLE OF OPERATION

A Load Cycle begins with a compressed air blowback

pulse to clear any isolated material parcles or dust

buildup that may remain on the apper discharge valve.

This acon ensures a ght vacuum seal for each Load

Cycle.

The loader then acvates our powerful, maintenance

free, brushless motor to create a vacuum, which draws

material into a chamber. Aer the load me seng has

expired, the vacuum motor is turned o and the nega-

ve pressure in the chamber is relieved. Material in the

chamber then falls through the boom, past the apper

while compressed air is pulsed through the lter to dis-

lodge any contaminants or nes that may have accumu-

lated. This cycle is repeated as many mes as necessary,

unl the unit is shut o by the rise of the conveyed ma-

terial in the area below the loader which trips the level

switch, removing the ‘demand’ signal.

Machine mounted units do not have a apper valve or

demand switch, but instead ulize a clear sight tube,

which mounts directly to the machine throat, with a sen-

sor to control loader operaon based upon the level of

material within the sight tube. The sensor may be either

a capacitance style, with sensivity adjustment, or a pair

of photoelectric sensors, an emier and a receiver.

The boom ange of a Machine Mount unit is normally

supplied undrilled to allow the customer to drill the ap-

propriate mounng paern for a parcular process ma-

chine.

2.0 UNPACKING AND INSPECTION

NOVATEC Vacuum loaders are shipped complete, with

all controls for automac operaon. The only ulies

required are a 115 volt power supply and clean, dry com-

pressed air at approximately 80 PSI.

Aer receipt of the unit, completely inspect it for dam-

age. All units are packaged securely at the factory. Please

report any damage to your carrier promptly.

3.0 SPECIFICATIONS

NOVATEC GSL Series vacuum loaders are completely

automac self-cleaning vacuum loaders designed to con-

vey virgin pellets and regrind materials from storage con-

tainers to drying hoppers or directly to process machines.

Each unit is shipped complete with all controls for imme-

diate operaon, and include a hardware package. The

hardware package includes 15 feet of exible vacuum

hose, hose clamps and a material pick up lance, plus a 12’

extension cable for remote mounng the standard Con-

trol Pendant.

The GSL is designed for mounng on drying hoppers.

The GSL can be modied for use as a machine mount

unit on processing machines by adding a machine mount

assembly with an 8, 12, or 16 lb. capacity site glass with a

height adjustable photo-eye demand switch.

OPTIONS:

2” Inlet: (in lieu of 1.5”)

Extended Wear Package: Recommended when loading

abrasive materials - contact factory

Alternate Glass Size: 12 lb glass (adds 4” to height) or

16 lb glass (adds 7” to height)

Kit includes glass, twist-lock plug and photo-eye

Alternate Mounng Flange (7” x 7” with 3.5” opening)

removes 1.5” from height

ACCESSORIES:

(one included with each GSL)

(Includes coupler, wand,

hose and clamps.) 1.5”and 2.0” O.D.

30mm dia., 2m cable

Sensor (for

machine mount models)

5

1. Install exible hose, secured with hose clamps at both

ends, from feed tube to material inlet tube of loader. A

Proporoning Valve, if included (see separate instruc-

ons) is installed on the material inlet tube with a com-

pression style coupling.

2. Plug power cord into 115 VAC power source. Note

amperage lisng on loader for correct voltage and capac-

ity.

3. Install exible compressed air line to the solenoid

valve ng (below lid hinge). Source should provide

clean, dry compressed air supply 80 -100 psi. Use only

full-ow quick disconnect ng for best blowback per-

formance. CAUTION: Use a second wrench to hold the

ng on the GSL securely while ghtening the hose t-

ng. DO NOT apply direct pressure, or damage the GSL

ng or an air leak could result. A compressed air lter

(sold separately) is recommended for protecon of pneu-

mac components.

Locate HINGE away from

operator for easy cleaning

GSL Mounng Plate

(see page 6)

Feed Tube Inserted

into material

Domed lter

stays in place

when lted.

115 VAC

Power Cord

Connect Fing on

Solenoid Valve to

Compressed Air

(Pilot for Blowback)

(Not visible)

Material Line

Connecon

Control Pendant

(see page 6)

4.0 INSTALLATION

4.1 GSL

1.

2.

3.

6

• New or exisng NOVATEC hoppers will allow

mounng the GSL directly. Hoppers with large

openings for 5” dump throat models will use the

VL-12 to VL-38 adaptor, included with the GSL unit.

You may bolt the loader base plate on the receiving

hopper securely, and then install the GSL cast cone

with the front hinge pin and rear ange locking tab.

CAUTION: FASTEN GSL FLANGE TO RIGID

MOUNTING SURFACE BEFORE OPERATING OR

TILTING THE HOPPER BODY. USE ONLY LOCK-

ING, CAPTIVE FASTENERS.

• For mounng to non-NOVATEC hoppers, note

your model of GSL and prepare the hopper to be

loaded with the appropriate cut-out and bolt pat-

tern according to the diagrams above. These have

been designed to allow for direct mount into several

non-NOVATEC mounng paerns.

• Secure fasteners should be employed, fastened per-

manently to the hopper lid to prevent possible drop-

ping into the hopper/material.

10.38” O.D.

9.00” Dia. Bolt Hole Circle

.3125” Dia. Typ. (4 places)

Alternate Mounng Flange (7” x 7” with

3.5” opening) removes 1.5” from height

7

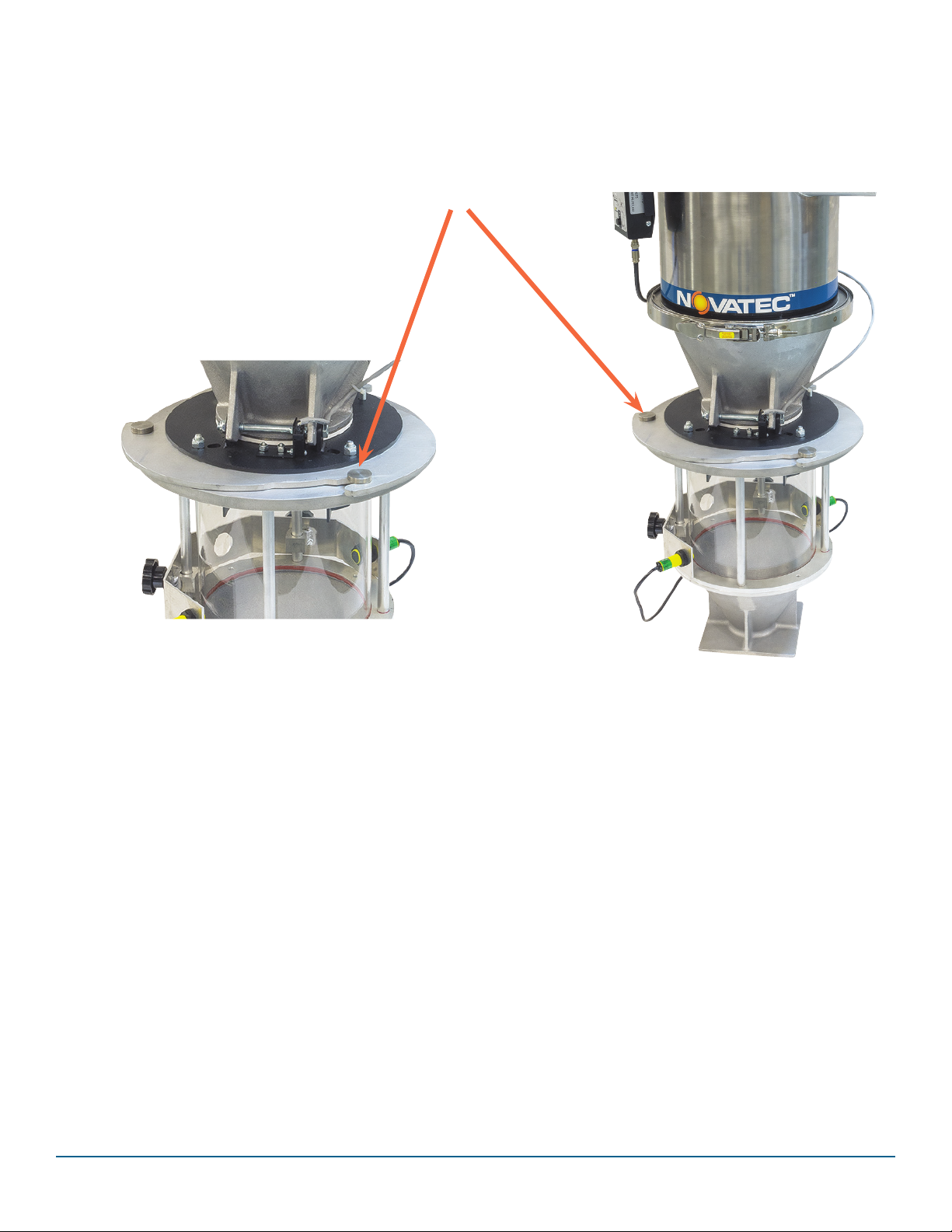

4.2 GSL MACHINE MOUNT MODELS

The upper part of the machine mount model sll lts for

ease of access to clean/replace lters.

Upper and lower parts of machine mount

model are connected together with a plate

that slides into place.

A detent pin locks the plate in place. GSL-19 with adjustable with oponal ma-

chine mount assembly and Photo Eye Level

Sensor installed.

8

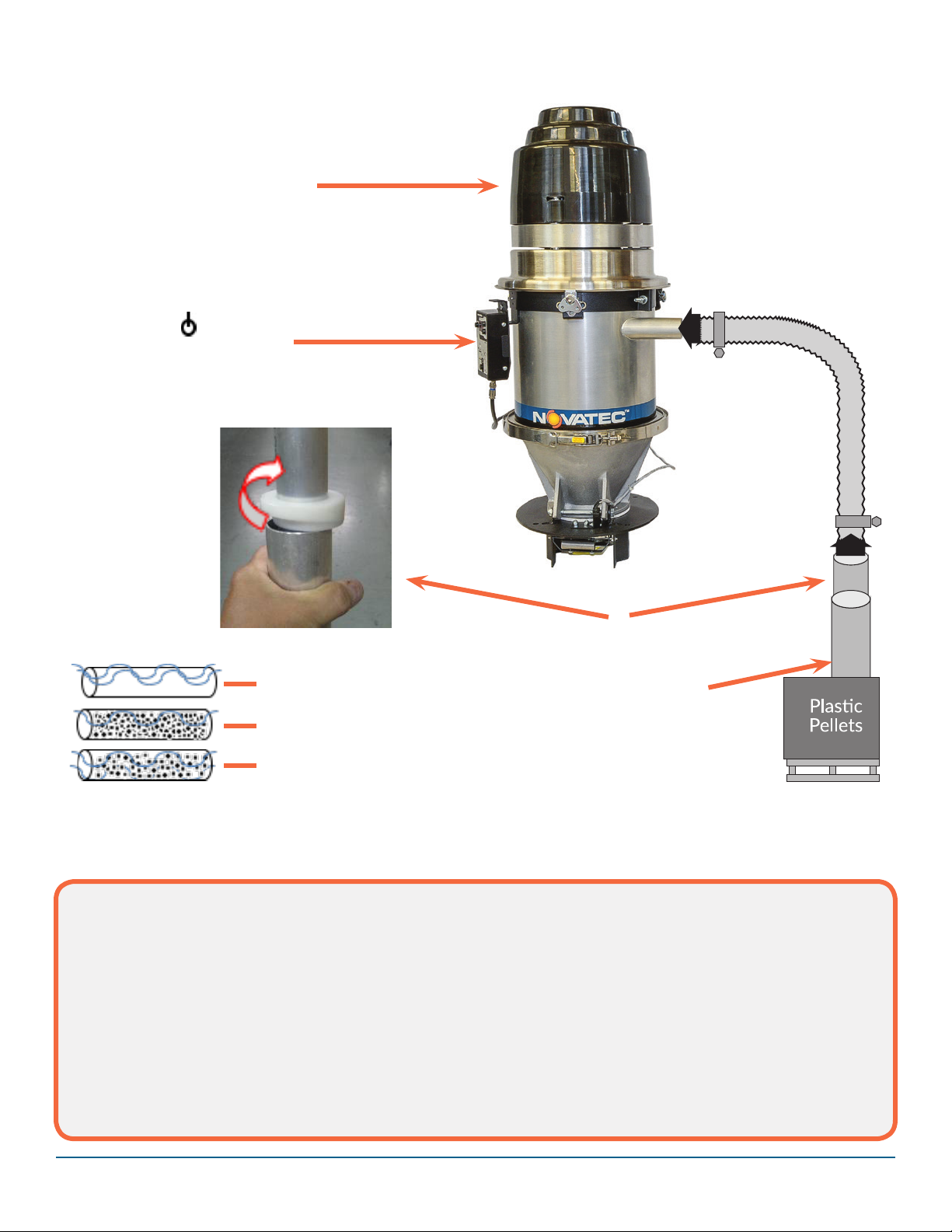

1. The feed tube joins air with material and it should

be plunged (and kept) in the material supply, but allow

upper secon of feed tube to remain above material

level.

2. Adjust load me. See next page for detailed in-

strucons on control sengs and opons.

3. To allow opmum loading and longest lter life,

adjust load me to ll the loader without over lling.

To idenfy opmal load me, operate the motor unl

material stops moving and note the corresponding ll

me. This means the loader is OVER FILLED. Sub-

tract 5 seconds from the over-lled me to limit pre-

mature lter blinding.

4. Rotate the feed tube ring for the best air to material

mixture. The best mixture of air and material will allow

material to ow eciently, with the right proporon of

conveying air, without clogging and without rapid hose

wear. Be sure material ows into loader consistently

from start to nish, without surging or oang at the

pickup or loader inlet.

3. Vacuum motor should ll loader

unl 5 seconds before pellets stop

moving through the convey hose

and no more.

Rotate to change air

inlet opening

2. Press buon to turn on

loader and adjust load me

with + buons.

Air inlet

4. Adjust conveying air with

feed tube ring

1. Assure that the feed tube

is inserted into material

Too much air…slow loading

and hose wear more likely

Too lile air…plugged

material line is possible

Good mixture of air and

material

9

Solenoid Valve

(Air) Connecon

6.0 ADJUSTING THE LOADER CONTROL

or disables loading.

Power is only disconnected

by unplugging the power cord.

POWER*

Press for On or O

Display shows “ON”

Force Alarm Reset

Motor Plug

Connecon

Demand Switch

Connecon

Power

Connecon

Pendant Cable Connector

Control Box

10

SELECT FUNCTION BUTTON

● Buon selects funcons for

viewing and/or changing.

● Selected funcon lights up, below.

● Silences Alarm (does not reset alarm)

STANDARD FUNCTIONS

Seconds per load

Default = 15s (suggested Max = 20s)

Do not exceed 30s / Do not overll

Damage may result

“XY”

X=loads between clean cycles

Y=air charge (Y*0.4s)

See Blowback Funcon descripon (p. 12)

‘No Load’ cycles to create alarm

“0” = Alarm disabled.

See Alarm Funcon descripon (p.12)

Seconds or minutes (M)

(Forced pause between Load Cycles)

VIEW and CHANGE SETTINGS

● Selected seng appears in window

● Increase (+) or decrease (-) values

● Display defaults to show “ON”

● Display shows “AL” for alarm condion

OPTIONAL FUNCTIONS

PROPORTIONING: Requires oponal Valve.

● LAYERS: # of alternang VIR/REG cycles per load.

‘A’ = Automac control calculated Layers.

TOTAL CONVEY TIME per Load

Regrind = (Motor On – Purge) * REG %

Virgin = (Motor On – Purge – Regrind)

NOTE: Divide these mes by LAYERS value for

individual layer cycles mes.

REGRIND: % of Convey Time for regrind

Uses specied me to empty the

material line. Inserted as nal interval of

total MOTOR ON me (does not extend

MOTOR ON me). Requires oponal Valve.

11

Loading and Purging

Although this term may not appear on all controls, it is

helpful to use for understanding the vacuum-on me of an

individual receiver. The total vacuum-on me of a loader

(the length of me the vacuum motor is “ON”) can be

referred to as FILL me. All funcons that happen while

the vacuum motor is “ON” (regrind proporoning, pocket

conveying, purging, etc.) is all part of the FILL me.

The vacuum me that a loader uses to introduce material

into a material conveying line is LOAD me. The term

may be thought of as ‘loading the material line’. This term

is important to understand when purging conveying lines,

to disnguish between the me the purge valve is opened

(LOAD me) compared to the me it is closed (PURGE

me). On loaders that have no purge valves, LOAD me

equals FILL me. On systems with purge valves, LOAD

me is just the rst part of the FILL me. Purge me is

the conclusion of FILL me.

The vacuum me that a pocket or purge valve is closed to

material ow, but vacuum air connues to ow thru the

conveying line to clean out the material conveying line is

referred to as PURGE me.

Because the funcons are idencal, the term PURGE me

is used for purging systems and pocket conveying systems

for cleaning out the conveying line aer loading.

Fill Time

(Vacuum Motor “ON”)

Vacuum

Motor “ON”

LOAD

Time

(purge

valve

open)

Times are set in seconds.

Purge or

Pocket

Valve

CLOSES to

Material

flow

PURGE

Time

(purge

valve

closed)

Vacuum

Motor “OFF”

Material Outlet, connected

to receiver Inlet

Solenoid: Connecon to con-

trol and connecon to com-

pressed air supply. Material #1 inlet,

typically Virgin

Material #2 inlet,

typically Regrind

12

7.0 INITIAL STARTUP

Press the Power Buon on the Control Pendant unl

‘ON’ appears on the display to enable loading.

IF a material demand exists, the loader will begin

loading.

NO LOAD ALARM FUNCTION

The NO LOAD ALARM is enabled through the control

pendant by entering a display value >0

when the No Load Alarm LED is illumi-

nated (see photo).

NO LOAD ALARM occurs when the

counter reaches the user selected Alarm

Set Point value.

• The Loader connues load aempts

aer the ‘Alarm’ Output is energized.

• If 10 cycles pass without the alarm

counter being cleared, the Loader will

shut down and ash “OF” on the pen-

dant control.

CLEARNING AN ALARM CONDITION:

• Pressing the ‘Select Buon’ will silence the ‘alarm’ out-

put. The alarm counter will connue.

• The alarm clears when the hopper is full.

• Aer Alarm Shutdown, press the power buon to clear

the alarm and restart operaon.

BLOWBACK FUNCTION

Blowback, when enabled for lter cleaning, pulses before

and aer any load cycle designated for blowback by the

control sengs.

Blowback also pulses briey at the beginning of each

load cycle, just as the motor begins operang. This blow-

back pulse is intended to clear any material residue from

the discharge apper and ensure a clean vacuum seal for

opmal loading.

13

8.0 ELECTRICAL CONNECTIONS FOR

LOADER OPTIONS

1. Remove the loader control enclosure, and care-

fully p the enclosure out without straining wires

connected to the control.

2. Locate the correct terminals for the device you

are connecng, as shown in the diagrams that fol-

low, and connect the wires carefully. Use care as

some terminals accommodate mulple wires.

3. Route the cable out of the control box, through

one of the slots in the side. Tightly install a e

wrap (not included) onto the cable, inside the

control enclosure to prevent the cable from being

pulled out of the box.

4. Tip control box back into place and ghten top

screw.

14

15

16

9.0 TROUBLESHOOTING

Most loader problems are a result of a dirty lter, air leaks or improper adjustments.

These items should be checked before assuming equipment failure.

Motor will not run A, B, C, H, and L

Inadequate or no vacuum D, E, F, G, J

Inadequate or no material ow D, E, F, and G, I, K

Motor runs but proporoning solenoid not operang L

CHECK CONDITIONS SOLUTION

A. Power Supply No voltage or voltage incorrect Check incoming

v o l t a g e a t o u t l e t p o w e r s u p p l y

B. Stop/Start Switch No voltage through switch Replace switch

C. Vacuum motor No voltage at motor See A,B, & L

D. Filter Filter dirty Replace lter

(Also see G & J)

E. Air Ducts Obstructed Remove obstrucon

F. Leaks in system Air leaking into system Replace gaskets &

repair leaks as necessary

G. Blowback air Low pressure Increase pressure

pressure incorrect (not to exceed 125 psi)

H. Limit switch No voltage through switch Replace switch

I. Load Time Chamber not lling suciently Increase load me

Chamber over-lling Decrease load me

J. Pulse rate Insucient to clean lter Increase rate

K. Dump me Insucient to allow complete Increase me

emptying of chamber

L. Pulse solenoid Correct voltage at solenoid Replace solenoid

17

18

10.0 WARRANTY

NOVATEC, INC. oers COMPREHENSIVE PRODUCT WARRANTIES on

all of our plascs auxiliary equipment. We warrant each NOVATEC man-

ufactured product to be free from defects in materials and workman-

ship, under normal use and service for the periods listed under “Warran-

ty Periods”. The obligaon of Novatec, under this warranty, is limited to

repairing or furnishing, without charge, a similar part to replace any part

which fails under normal use due to a material or workmanship defect,

within its respecve warranty period. It is the purchaser’s responsibility

to provide Novatec with immediate wrien noce of any such suspect-

ed defect. Warranted replacement parts are billed and shipped freight

pre-paid. The purchaser must return the suspect defecve part, freight

prepaid and with idenfying documentaon to receive full credit for

the part returned. Novatec shall not be held liable for damages or delay

caused by defects. No allowance will be made for repairs or alteraons

without the wrien consent or approval of Novatec.

The provisions in equipment specicaons are descripve, unless

expressly stated as warranes. The liability of Novatec to the purchaser,

except as to tle, arising out of the supplying of the said equipment, or

its use, whether based upon warranty, contract or negligence, shall not

in any case exceed the cost of correcng defects in the equipment as

herein provided. All such liability shall terminate upon the expiraon

of said warranty periods. Novatec shall not in any event be held liable

for any special, indirect or consequenal damages. Commodies not

manufactured by Novatec are warranted and guaranteed to Novatec

by the original manufacturer and then only to the extent that Novatec

is able to enforce such warranty or guaranty. Novatec, Inc. has not au-

thorized anyone to make any warranty or representaon other than the

warranty contained here. Non-payment of invoice beyond 90 days will

invalidate the warranty. A renewed warranty can be purchased directly

from Novatec.

Please note that we always strive to sasfy our customers in whatever

manner is deemed most expedient to overcome any issues in connec-

on with our equipment.

Note: All warranty periods commence with the shipment of the equip-

ment to the customer.

(Except 1-Year on Non-Novatec Buy-Out Items)

NovaWheel™ Dryers *

Dual Bed Dryers

NovaDrier *

NDM-5 Membrane Dryer

Gas-Fired Process Heaters

Gas-Fired Regeneraon Heaters

Drying Hoppers

Central Drying Hopper Assemblies

Heater/Blower Units and Hot-Air Dryer

Silo Dehumidiers

NovaVac Dryers *

Nitrodry Nitrogen Dryers

DryTemp Plus

FlexTouch™ Series Controls

FlexXpand™ Series Controls

OpFlex™ Series Controls

PLC Communicaons Modules

Greenboard Communicaons Modules

LOGO! Mini PLC

MCS-600 Series Controls – (Distributed I/O)

MCS-400 Series Controls

CL Silo Manager

MoistureMaster®

Resin Blending and Feeding to Include:

WSB Blenders, MaxiBatch & Feeders *

Gaylord Sweeper Systems

C and NC Bessemer Series Cuers

NPS Bessemer Series Pullers

NPC Mini Puller/Cuer

All NS Series Servo Saws

Rx SmartMed Extrusion Products

All Cooling and Vacuum Tanks Manufactured by Novatec

GSL Series Vacuum Loaders

GlassVu Loaders, Receivers and Hoppers

VL/VLP Series Loaders

VRH, VR, VR-FL, VRP & VRM Series Receivers

Compressed Air Loaders

AL-B Barrel Loader

Cyclone Dust Collectors

Conveying System Accessories

Surge Bins

Valves and Accessories

Electronic Metal Separators

Quick Select Manifolds

Tilt Tables

Filter Dust Collectors

Drawer Magnets

Velocity Control Valves

** VPDB Vacuum Posive Displacement Pumps

** SVP Vacuum Pumps

** MVP Vacuum Pumps

** Railcar Unloading Systems

** - When a MachineSense® data plan is acvated for products with **, Novatec automacally extends the warranty to 5 years.

The data plan must be acvated within 60 days aer product shipment, and remain acve through the warranty period to maintain extended warranty

eligibility. The rst 6-months of data plan usage is free from Novatec.

Infrared Dryers

UltraVac Vacuum Pumps

Vacuum Regenerave Blower Pumps

Custom Equipment of any kind unless otherwise specied

19

Exclusions:

Roune maintenance/replacement parts are excluded from the war-

ranty. These include, but are not limited to: hoses, desiccant, lters,

lter elements, wiper seals, gaskets, dew point sensors, infrared lamps,

motors, internal solenoids, fuses and motor brushes. Use with abrasive

materials will void the warranty of any standard product. Wear resistant

opons may be available to extend usable service life with abrasive ma-

terials. Novatec reserves the right to limit the warranty if the customer

installs replacement parts that do not meet the specicaons of the

original parts supplied by Novatec.

1. NovaDrier™ and NITROdry™ warranty is void if coalescing lters are

not replaced on a 6-month or yearly basis (per instrucon manual)

and/or membrane has been exposed to ozone.

2. NovaVac Dryer -The ability of the canisters to hold vacuum will be

compromised if the vacuum seal edge is damaged from mishandling.

We do not warranty canisters damaged from improper handling. We

do, however, warranty the seals.

3. LOAD CELLS on our WSB’s are covered by Novatec standard warran-

ty as long as they have not been damaged from improper handling.

4. Desiccant Wheel Warranty will be void if the wheel has been exposed

to plascizer, dust or other contaminants as a result of negligence on

the part of the processor.

5. DryTemp+ - We assume no responsibility from equipment failures

resulng from untreated or improperly treated water.

1. Repaired or altered without wrien approval of NOVATEC unless

such repair or alteraon was, in our judgment, not responsible for the

failure

2. Which has been subject to misuse, negligence, accident or incorrect

wiring by others

3. Warranty is void if processing rates exceed manufacturer-recom-

mended levels or if damage is caused by ineecve power isolaon

and/or power spikes/sags or incorrect installaon.

NOTE: All condions and content of this warranty are subject to chang-

es without noce.

Drying > Conveying > Blending > Downstream

222 East Thomas Avenue

Balmore, Maryland 21225

www.novatec.com

Phone

410-789-4811 or 800-938-6682

24 Hour service: 800-938-6682

Fax: 410-789-4638

Email

Parts: parts@novatec.com

Service: service@novatec.com

Sales: sales@novatec.com

This manual suits for next models

2

Table of contents