8

8QILOWHUHG:DWHU%\SDVV

/RRS&XW&DSSHG

*URXQG6WUDS5HTXLUHG%HFDXVH

RI%UHDNLQ&RQWLQXLW\

)LOWHUHG:DWHU/LQHLQ+RPH

Fig. 1.

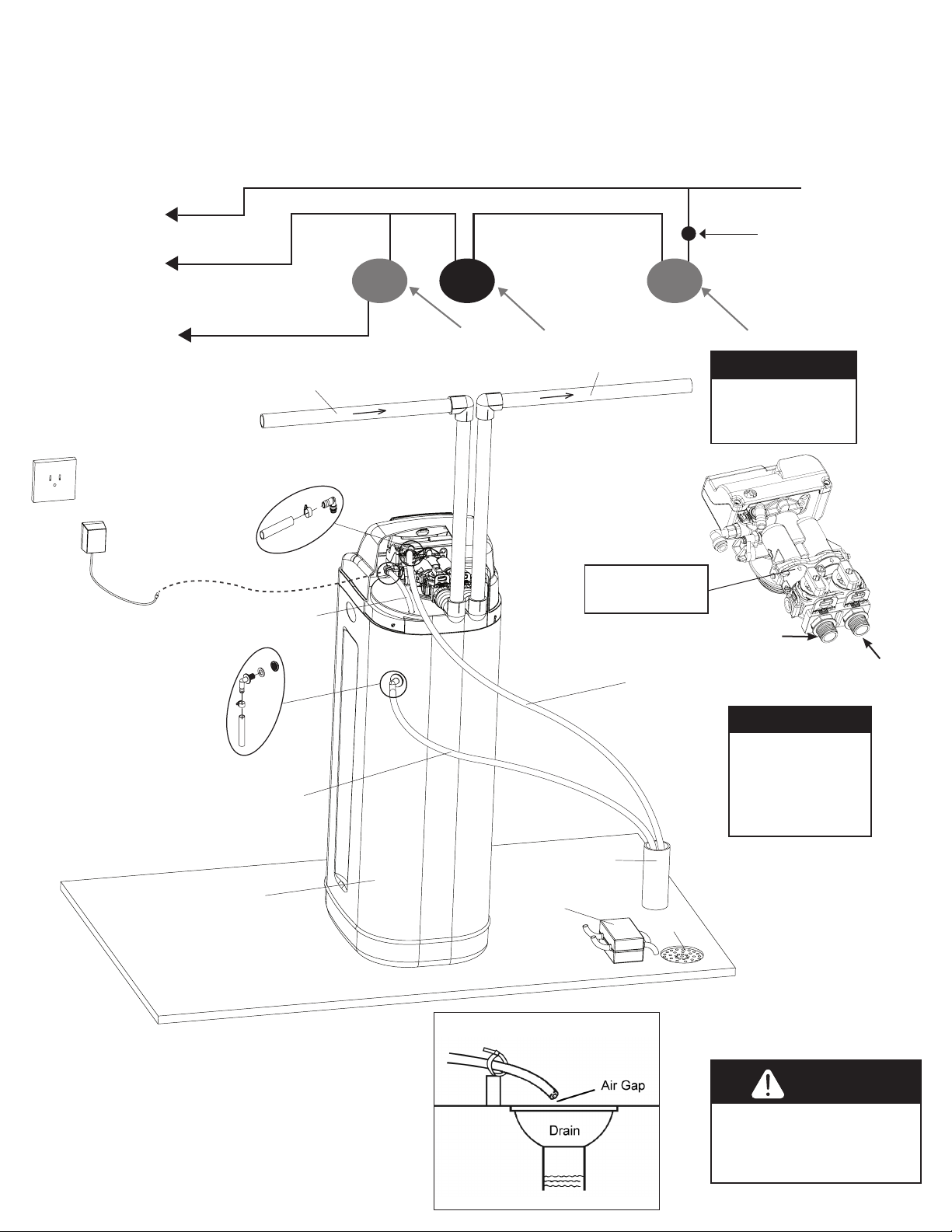

BEFORE INSTALLATION

Make sure you have a copy of your most recent water test results. If your water has not been tested previously you can contact

your supplier of this product to obtain a water sample bottle to be sent to one of our facilities for a free analysis. It is important

that this product not be installed until you have this information.

In all cases where metal pipe was originally used and is later interrupted by poly pipe or the Noryl bypass valve or by physical

separation, an approved ground clamp with no less than #6 copper conductor must be used for continuity, to maintain proper

metallic pipe bonding.

Inspecting and Handling Your New System*

Inspect the equipment for any shipping damage. If damaged, notify the transportation company and request a damage

inspection. Damage to cartons should also be noted.

Handle the conditioner unit with care. Damage can result if it is dropped or set on sharp, uneven projections on the floor.

Do not turn the conditioner unit upside down.

To Insure this Product Functions Properly:

Your feed water line size to the unit must be a minimum of 3/4 inch with an operating pressure of no less than 30

psi and no more than 125 psi.

MECHANICAL:

Do not use petroleum based lubricants such as petroleum jelly, oils or hydrocarbon based lubricants.Use only 100% silicone

lubricants (grease packet provided in parts kit). All plastic connections should be hand tightened only. Teflon tape may be used

on connections that do not use an O-ring seal. Do not use pliers or pipe wrenches except where indicated by Nut shape (eg. pipe

adapters) All plumbing must be completed according to local codes. Soldering connections should be done before connecting

any pieces to the pipe as excessive heat can damage them.

Tools Required for Installation:

NOTE: We recommend installation only be completed by a competent installer or

plumbing professional to insure this product is installed in accordance with local

plumbing codes.

sTwo adjustable wrenches

sAdditional tools may be required if modification to home plumbing is required.

sPlastic inlet and outlet fittings are included with the conditioner. To maintain full valve flow, 3/4” or 1” pipes to and from

the conditioner fittings are recommended. You should maintain the same, or larger, pipe size as the water supply pipe, up

to the conditioner inlet and outlet.

sUse copper, brass, or PEX pipe and fittings.

sSome codes may also allow PVC plastic pipe.

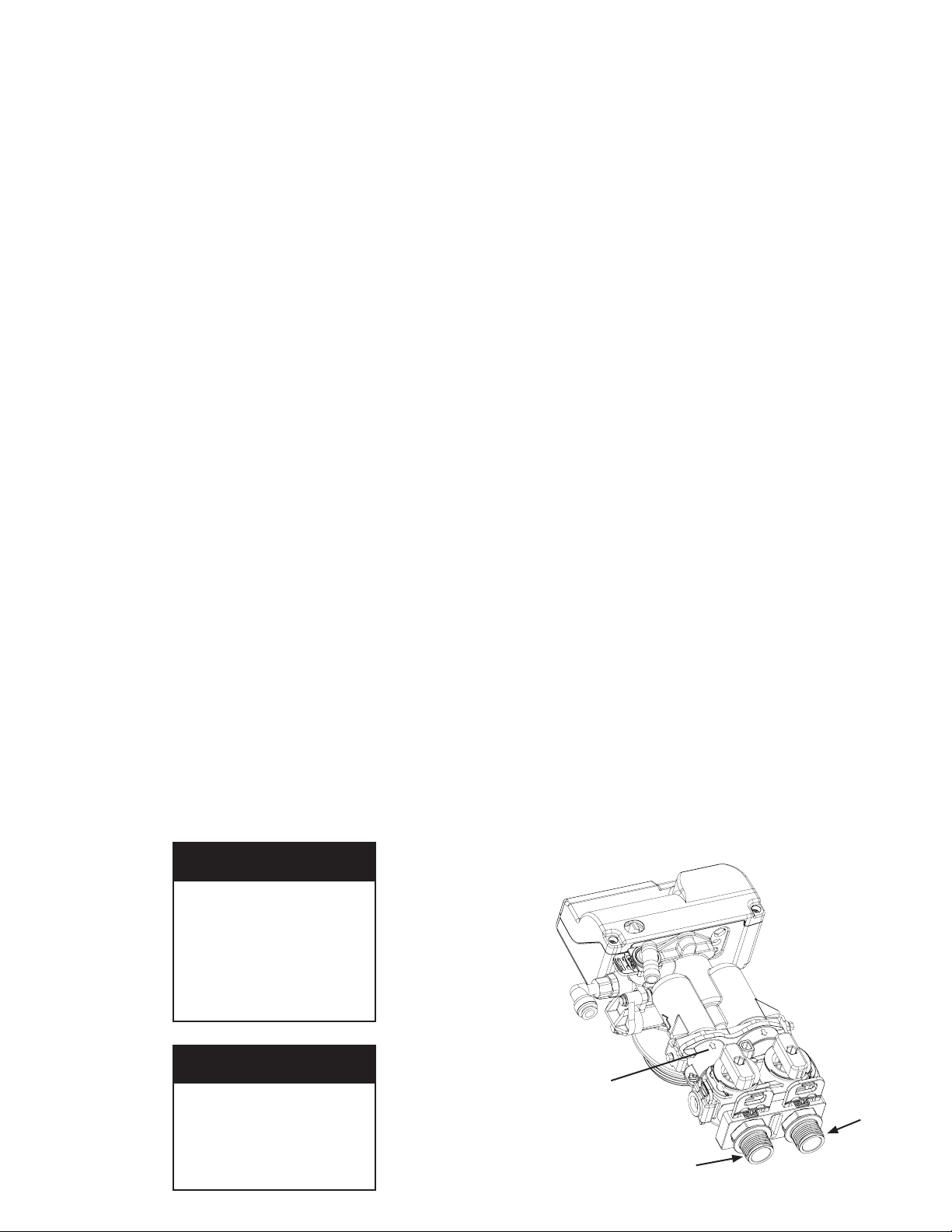

sALWAYS install the included bypass valve, or 3 shut-off valves. Bypass valves let you turn off water to the conditioner for

repairs if needed, but still have water in the house pipes.

s5/8” OD drain line is needed for the valve drain. A 10’ length of hose is not included with some brands.

NOTE

All government codes and

regulations governing the

installation of these devices

must be observed.

NOTE

If a severe loss in water

pressure is observed when

the conditioner unit is ini-

tially placed in service, the

conditioner tank may have

been laid on its side during

transit. If this occurs, back-

wash the conditioner to

“reclassify” the media.

*NOTE

Due to transportation

and climatic conditions all

connections including the

valve to the tank need to be

checked at time of

installation and tightened if

necessary.

NOTE

Check your local electrical

code for the correct clamp

and cable size.

CAUTION!

If the ground from the

electrical panel or breaker

box to the water meter or

underground copper pipe

is tied to the copper water

lines and these lines are cut

during installation of the No-

ryl bypass valve and/or poly

pipe, an approved grounding

strap must be used between

the two lines that have been

cut in order to maintain

continuity. The length of the

grounding strap will depend

upon the number of units

being installed and/or the

amount of copper pipe being

replaced with plastic pipe.

See Fig. 1.