5

Taste & Odor Filter (Activated Carbon)

Unpleasant tastes and doors caused by chlo-

rine or organic substances, such as decayed

vegetation and run off, are absorbed by top

quality activated carbon. The filter will auto-

matically backwash to a predetermined

schedule. This frees the bed of accumulated

impurities and readies it for operation again.

Multi-Media Filter (Sediment)

Suspended particulate matter such as clay

and silt, which gives water a cloudy appear-

ance, is trapped in the filter bed to produce

clean, clear water. A variety of gravel and

sand facilitates more thorough backwashing

and prevents channeling. Periodic backwash-

ing cleans the bed.

Neutralizing Filter

The neutralizing filter contains blended media

which raises the pH of acidic water and neu-

tralizes its corrosive characteristics. In addi-

tion to protecting pipes, plumbing fixtures

and appliances, this filter also facilitates the

removal of iron and manganese by raising

the pH. This enables an iron filter to be used.

Periodic backwashing cleans the bed. Addi-

tional media may be required six months to

two years after installation, depending on the

water’s pH.

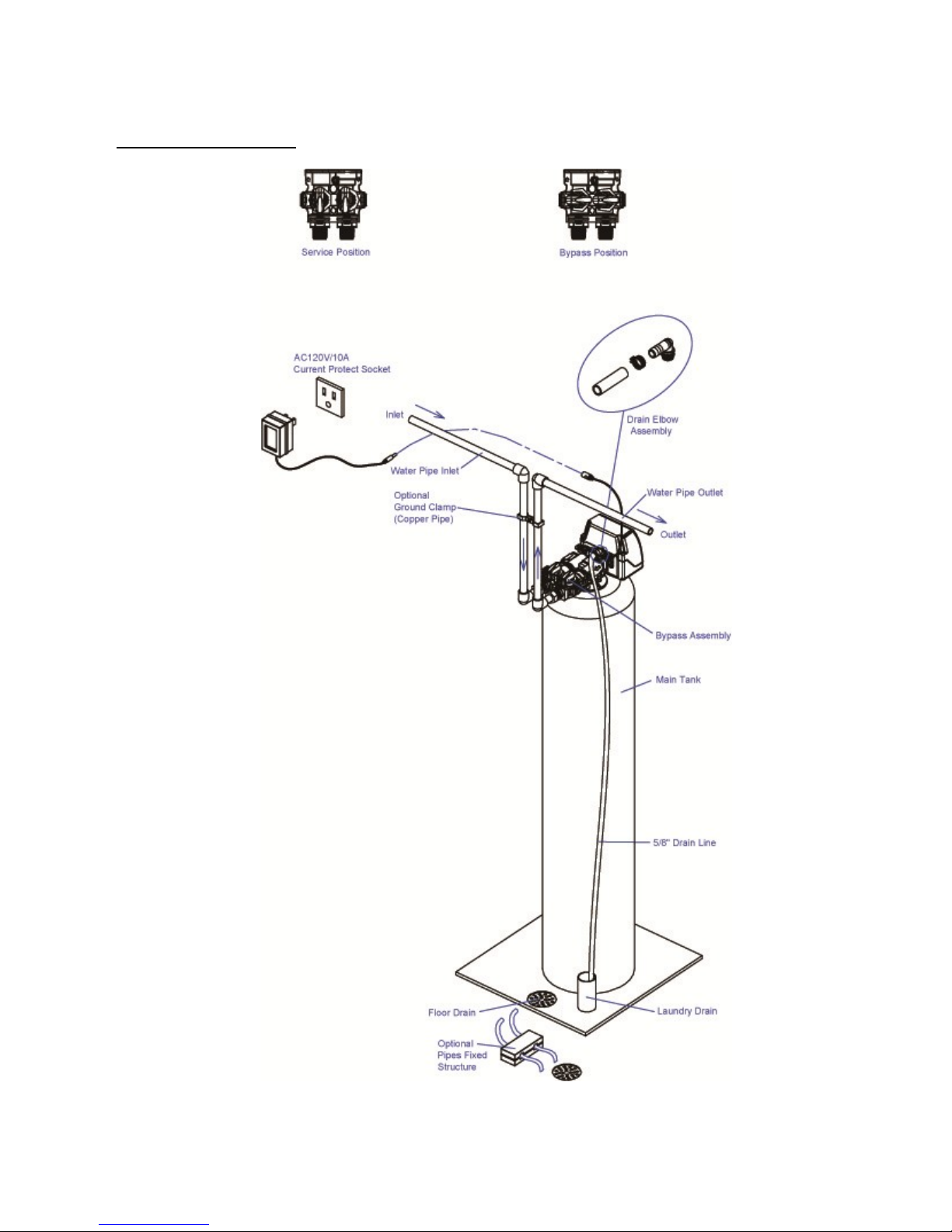

Before Starting Installation

Tools, Pipe, and Fittings, Other Materials

Pliers

Screwdriver

Teflon tape

Razor knife

Two adjustable wrenches

Additional tools may be required if modifi-

cation to home plumbing is required.

Plastic inlet and outlet fittings are included

with the filter. To maintain full valve flow,

3/4” or 1” pipes to and from the filter fit-

tings are recommended. You should main-

tain the same, or larger, pipe size as the

water supply pipe, up to the softener inlet

and outlet.

Use copper, brass, or PEX pipe and fittings.

Some codes may also allow PVC plastic

pipe.

ALWAYS install the included bypass valve,

or 3 shut-off valves. Bypass valves let you

turn off water to the filter for repairs if

needed, but still have water in the house

pipes.

5/8” OD drain line is needed for the valve

drain. A 10’ length of hose is included.

with some models.