This installation manual must be given to the customer and kept safely during the entire period of use!

2

EN

General instructions

• Please read the installation manual

completely before using the product for

the first time! Take note of the comments

and comply with the safety notices and

warnings!

Make sure that all generally acknowledged

legal and other binding regulations for the

prevention of accidents and protection of the

environment, national regulations and ack-

nowledged engineering and technical rules

for safe and correct execution of the work

are observed.

• Check that the fasteners and fixing

materials provided are suitable for the site

conditions. Only use suitable fasteners

and fixing materials.

• Perform each step in sequence in

accordance with the installation drawings!

• Only use proper and suitable tools!

• Only work on the leveller when it has

been made non-operational.

• Failure to observe these precautions

may result in serious injury and material

damage!

• The components that are to be used are

manufactured from high-grade, durable

and solid materials. Even so, care must

be taken during installation in order to

avoid damage.

• If parts suffer damage, always replace

them with OEM parts. If you fail to do so,

correct operation of the leveller can no

longer be guaranteed! Furthermore,

this voids the warranty!

Check the following before installation:

Check the following items before installation:

• Does the electrical supply that is available

correspond to the requirements for the

leveller?

• Are suitable cables and fuses available?

• In the case of models that are to be

installed in a prepared pit: Does the pit

correspond to the relevant installation

drawings and has an empty conduit

measuring 70 mm in diameter been

provided to allow insertion of the cable?

Only start installation work if all of the

conditions are satisfied.

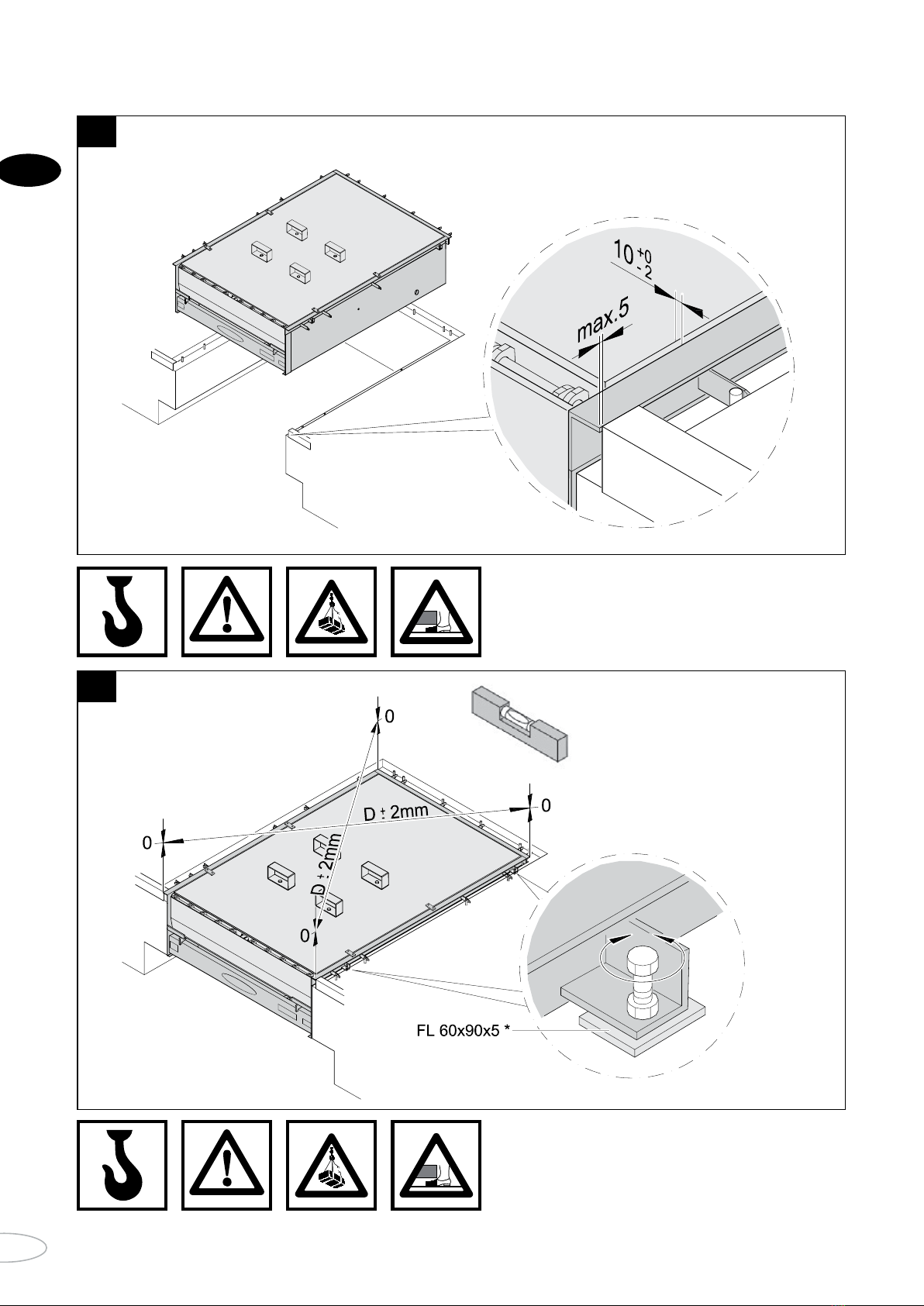

To check dimensional accuracy, measure

the length and width of the pit, the height of

the front and rear sides and the diagonals.

The length of the diagonals (X) may not differ

from each other by more than 10 mm.

Instruction: The leveller must be installed so

that it is perfectly horizontal across its

width. If not, leveller operation may be

adversely affected. There is also a risk of

damage to the leveller.

Tools required for installation

You require the following tools for the instal-

lation work:

• ESAB caddy 200 (5¬200A) welder (typical

example).

• ESAB OK 48.00 3.25 welding rod (typical

example).

Lifting equipment

• Forklift truck: Lifting capacity of at least

35 kN, fork length 2000 mm, or

• Crane: Lifting capacity of at least 35 kN

in the area where work must take place.

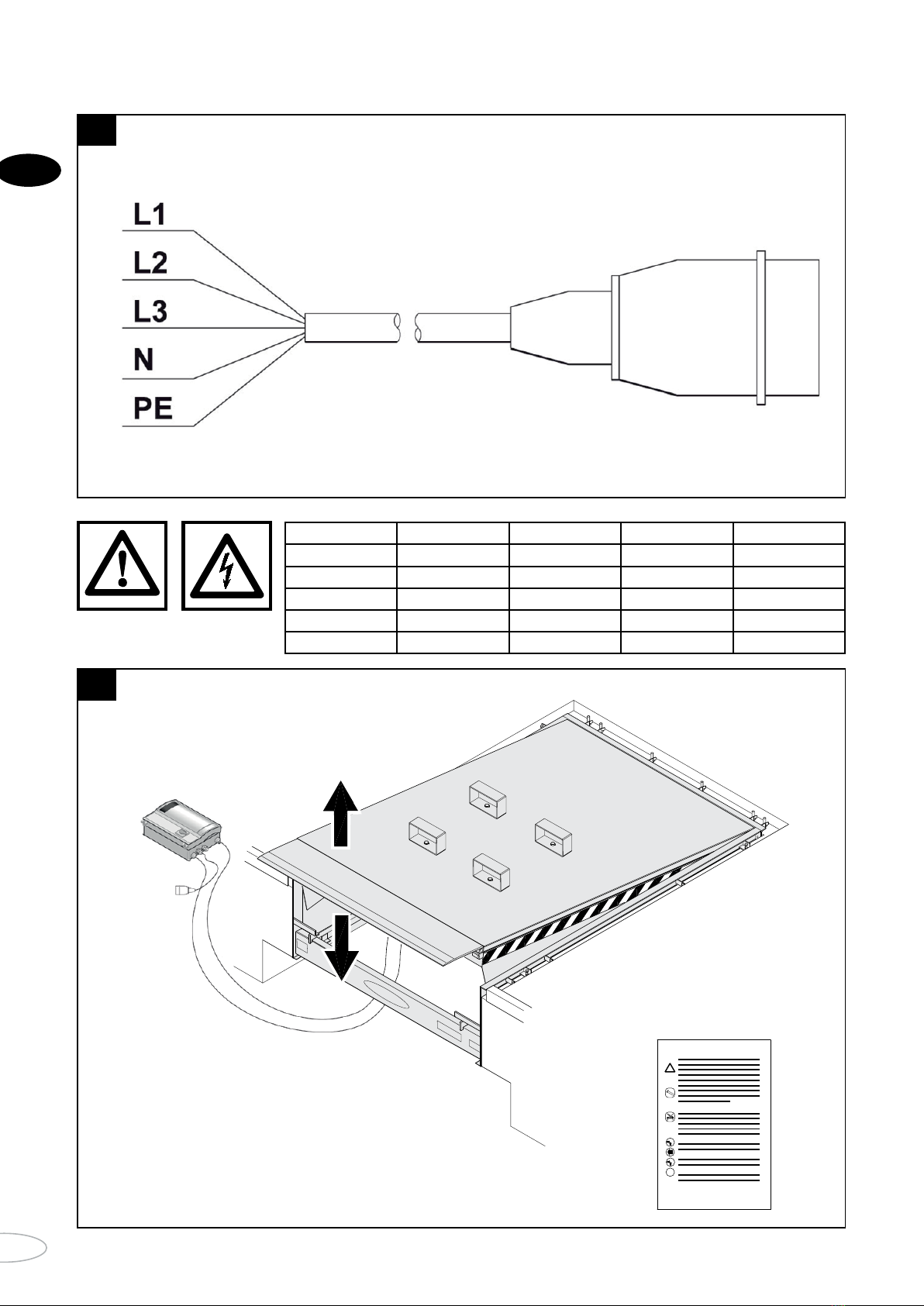

Electrical connections

• Cable: 7 x 0.75mm²

• Motor cable: 4 x 1.5mm²

Functional check

• Check all operating modes of the level-

ler upon completion of the installation

work. To do so, use the leveller test

report.

• Fill out the test report truthfully and

sign the entry.

• After doing so, hand this installation

manual together with the other docu-

ments to the customer.

Commissioning

• The leveller may only be used for the

first time after handing over the decla-

ration of conformity.

• Give the users instruction in how to

operate the leveller. Do not allow third

parties (e.g. visitors) to operate the leveller.

• This installation manual must be given

to the customer and kept safely during

the entire period of use!

• Do not make any changes to the software

for the programmable control unit.

• Changes or additions to the product that

has been delivered may only be made by

the supplier.

• The manufacturer is not liable for

damage caused by non-observance of

the installation manual or improper use.

• Please note that the valid regulations

require the leveller to be inspected by an

expert once a year.

• Maintenance must be performed each

year or every 5000 cycles.

2. General instructions

A malfunctioning leveller may cause

personal injury and material damage to

goods. Only use the leveller when in

proper operating condition.

Warning

++ WARNING +++ WARNING +++ WARNING ++

Movements performed by the leveller

may cause injury to people and damage

to goods.

• Make sure that no people or objects

are in the vicinity of the leveller

when it is moving.

• Never use the leveller to raise people

or objects.

Warning

++ WARNING +++ WARNING +++ WARNING ++

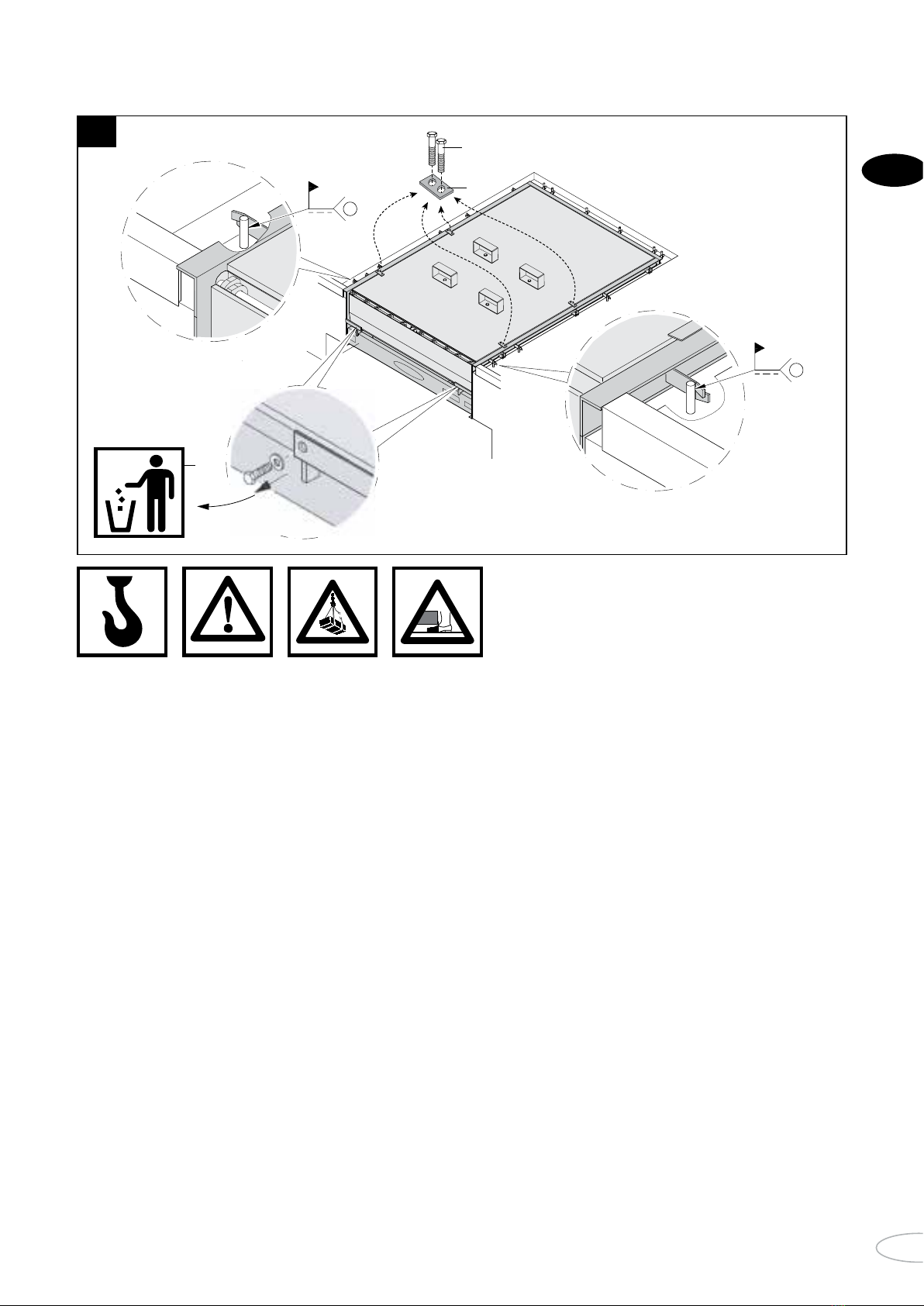

2.7

2.1

2.5

2.6

2.4

2.2

2.3

• When performing all installation

tasks, switch off the power supply and

secure the system to prevent it from

being switched on by an authorised

person.

• During installation, parts can drop,

which may result in injury to people

and damage to goods.

• Contact with electrically live compo-

nents may result in electric shock.

Make sure that the customer's elec-

trical system has been installed in

accordance with valid safety requi-

rements.

• Never connect a mains voltage supply

to the control unit; this will result in

irreparable damage to the electronics.

• Only perform welding and grinding

tasks on the leveller if expressly

permitted in the position in question.

Ensure adequate ventilation in order

to prevent build-up of an explosive

atmosphere of dust and other com-

bustible materials.

Warning

++ WARNING +++ WARNING +++ WARNING ++

X1

X2

X1 = X2

(± 10 mm)

• The area of application of this leveller

is described in the EN 1398 standard.

• Installation, repairs, maintenance

and dismantling must be carried out

by qualified professionals.

• During commissioning, the qualified

technician doing the work must be

alert to possible hazards and check

that the leveller operates correctly.

Read this first!

++ WARNING +++ WARNING +++ WARNING ++