novomatics Turbitronic P User manual

Novomatics Manual Turbitronic P

2

Contents:

1. Safety .........................................................................................................3

1.1. Safety precautions............................................................................................3

1.2.Computer and printer connections....................................................................4

2.Introduction......................................................................................................5

3.Features of Turbitronic P.................................................................................6

4.Installations......................................................................................................7

4.1.Instrument installation........................................................................................7

4.2.WinTurbi Software installation...........................................................................8

4.2.1.Installation of WinTurbi software from CDROM......................................8

Installation of WinTurbi software from Internet.................................................8

Installation of Turbitronic P device driver..........................................................8

5.Safety Lock – Turbitronic P version.............................................................. 10

6.Principle of temperature measurement.........................................................12

7.Starting a first measurement.........................................................................14

8.Program parameter settings..........................................................................17

9.Reload a measuring file.................................................................................18

10.Stop settings between the measurements..................................................18

11.Calibration of relevant parameters..............................................................19

11.1.Temperature calibration.................................................................................19

11.2.Rotation speed calibration.............................................................................19

11.3.Time calibration..............................................................................................19

11.4.Turbidity calibration........................................................................................19

11.5.Zero calibration..............................................................................................20

12.Operation modes..........................................................................................22

12.1.Change the operation mode..........................................................................22

12.2.Change the passcode....................................................................................23

13.Turbidity calibration standards...................................................................24

14.Failure detection and hazards.....................................................................26

14.1.Failure detection.............................................................................................26

15.Photocell cleaning instructions...................................................................27

15.1.Inspection of photocell operation..................................................................27

15.2.Photocell cleaning procedure........................................................................27

16.Failure check-list..........................................................................................29

16.1.Failure and problem curing ...........................................................................29

Appendix30

Technical Specification ....................................................................................31

Spare parts and test materials .........................................................................32

Factory and head office....................................................................................33

Distributors34

Novomatics Manual Turbitronic P

3

Read this chapter carefully before the

instrument will be taken into operation

1. Safety

Read operation manual before starting to work with the instrument. Make sure, that every

operator fully understands every function of the instrument and each of its components.

1.1.Safety precautions

1. Before connecting the Turbitronic P to the power supply:

Ensure that the MAINS switch at the front panel is in off position

Ensure that the power voltage of your mains socket corresponds to the power volt-

age of the instrument

Ensure that the power cable plug is connected only to a power socket that has a

protective earth contact. This applies equally, if an extension cable is used: the cable

must contain an earth conductor!

2. To effect grounding of the instrument case, the power plug must be inserted before

connections are made to a computer or printer. The power plug must remain con-

nected until all other units have been connected or disconnected.

3. Any interruption of the ground connection (inside or outside the instrument) is pro-

hibited.

4. The instrument must be disconnected from all voltage source before it is opened for

any adjustment, replacement or repair. The manufacturer does not take any re-

sponsibility for any adjustments, maintenance by the user. Consult NOVOMATICS or

your distributor, if repairs seem to be necessary.

Novomatics Manual Turbitronic P

4

5. Whenever it is likely that the safety of the instrument has been impaired, it should be

made inoperative and secured against any unintended operation. Safety could be

impaired if:

(a) any case or cable shows visible damage,

(b) the instrument fails to perform the intended operation,

(c) it has been subjected to prolonged under unfavorable storage conditions,

(d) it has been subjected to severe transport stress.

1.2. Computer and printer connections

Before making any connections to a host computer or printer, ensure that the instrument

is switched OFF. Ensure that the power plug is inserted. Otherwise, the instrument

and/or the host computer may take damage because of static discharge.

Novomatics Manual Turbitronic P

5

2. Introduction

This chapter is providing information on the basic concept of the turbidity measurements.

Turbidity is defined as an optical property of a liquid caused by light scattering and absorption.

This state will be caused by unsolved particles, for instance fine polymers or organic material.

These particles solved in a liquid lead to haze or turbidity, if the light falls through the liquid.

Easily said, turbidity is the opposite of clearness.

In the past, the turbidity detection could be determined on the manual way only. This test

method had many sources of error and uncertainty due to poor reproducibility, variances in

heating and cooling of the sample, inaccurate turbidity determination, etc.

As the turbidity measurement must be combined with the temperature measurement in case of

the Turbitronic P, a special white LED photocell-system has been designed. This fiberglass

photocell-system measures the absorption of the white light beam passing through the test tube.

This makes the photocell more sensitive for low turbidity measurements.

The output signal of the photocell detection circuit decreases non-linear with increasing turbidity

within the relevant turbidity range. The instrument is factory calibrated for turbidity but the

operator is requested to approve it periodically. The user can determine which turbidity value is

recognized as the cloud or clear point by program definition.

The photocell-system for turbidity measurement in the Turbitronic P has proven to be a rugged

and reliable device, designed for continuous use in factory environment.

Novomatics Manual Turbitronic P

6

3. Features of Turbitronic P

The Turbitronic P is a fully automatic turbidity measuring unit for the determination of cloud

points and opalescence turbidity changes related to temperature. The main features of the

Turbitronic P are:

- Highly reproducible determination of turbidity of water based polymers versus

temperature and time

- device independent turbidity measuring values expressed in NTU

- Highly reproducible cloud point detection and documentation

- Automatic microprocessor controlled test system for production and quality control

applications in industrial production processes and R&D.

- Time-saving, fully automatic test method, independent on the analyst or circumstances.

- Accurate, reliable and easy to operate precision test system as well for laboratory use

as for the production.

- Cost savings by higher production yields, improved final product quality and less labour

costs.

- Different temperature profiles predefined by factory or user.

- Fast calibration procedure to define the turbidity detection range by user with standards

references

- User definable stirring speed control to depress bubbles and to improve the accuracy.

- User definable temperature ramp control to improve the accuracy.

- Automatic controlled measuring of sample under test for time saving.

- Measurement result overview and comparison with date and time of the last 20

measurements by optional printing.

- User friendly for a high measurement efficiency.

- Use to use Windows software for remote control of the instrument via USB

Novomatics Manual Turbitronic P

7

4. Installations

4.1. Instrument installation

The Turbitronic P is an automatic test instrument for desktop use. It includes all required

mechanic and electronic components and requires no installation experience.

When the Turbitronic P is put into operation, the following three connections must be made:

1. The main cable for power supply. Please note, always an earth connection is available

at the wall socket.

2. The USB cable between Turbitronic P and your Windows computer.

3. The two water hoses for outer water circulation. Connect these to a water tap (inlet)

nearby and water drain (outlet). Open the water tap when operating the instrument. Close

it when not needed to prevent any water leakage in operator’s absence. If unfortunately

closed the instrument is not damaged but cooling times can be much longer. The water

flows only when cooling is needed so that water consumption is low.

When the connections have been made, the equipment can be switched on by the main switch

on front panel. If the self test proceeds without any failure the light of the ready led is

illuminating after two seconds.

Novomatics Manual Turbitronic P

8

4.2. WinTurbi Software installation

There are two packages needed for instrument operation. Before starting make sure that the

instrument is off and the USB cable is not connected to the computer.

4.2.1. Installation of WinTurbi software from USB flash drive

1. Insert the USB flash drive to install WinTurbi software

2. Start the program winturbisetup.exe

3. Follow the default adjustments by pressing Next

Installation of WinTurbi software from Internet

1. Visit: http://www.novomatics.de/downloads/

2. Login in with username and password

3. New users please fill out the registration request to receive login details

4. Download winturbisetup.exe

4. After downloading from Novomatics server start the program winturbisetup.exe

manually

5. Follow the default adjustments by pressing Next

6. The WinTurbi will be installed, USB driver is placed at {install path}\driver, for

example:

c:\program files\novomatics\winturbi\driver

Installation of Turbitronic P device driver

1) USB Driver installation

Please note WinTurbi operation is fully verified for Windows 10 only.

Execute CDM21224_Setup.exe as administrator found on your WinTurbi CDROM

or within your WinTurbi installation path.

Figure 1 Setup Executable Run as administrator

Novomatics Manual Turbitronic P

9

You may see a message from ‘User Access Control’ asking ‘Do you want to allow this app to

make changes to your PC? If so, click yes to continue.

Press the Extract button. Follow all installation including license terms agreement acceptance

shown and the driver will be automatically installed. From a legal point of view, the user must

accept the license terms of the driver. Successful installation is shown in Figure 7 wizard

Figure 2 Driver Installation Completition

Switch on the instrument and make sure it is connected to PC via USB cable. The instrument

appears as UMFT4222PROG within device manager now.

Novomatics Manual Turbitronic P

10

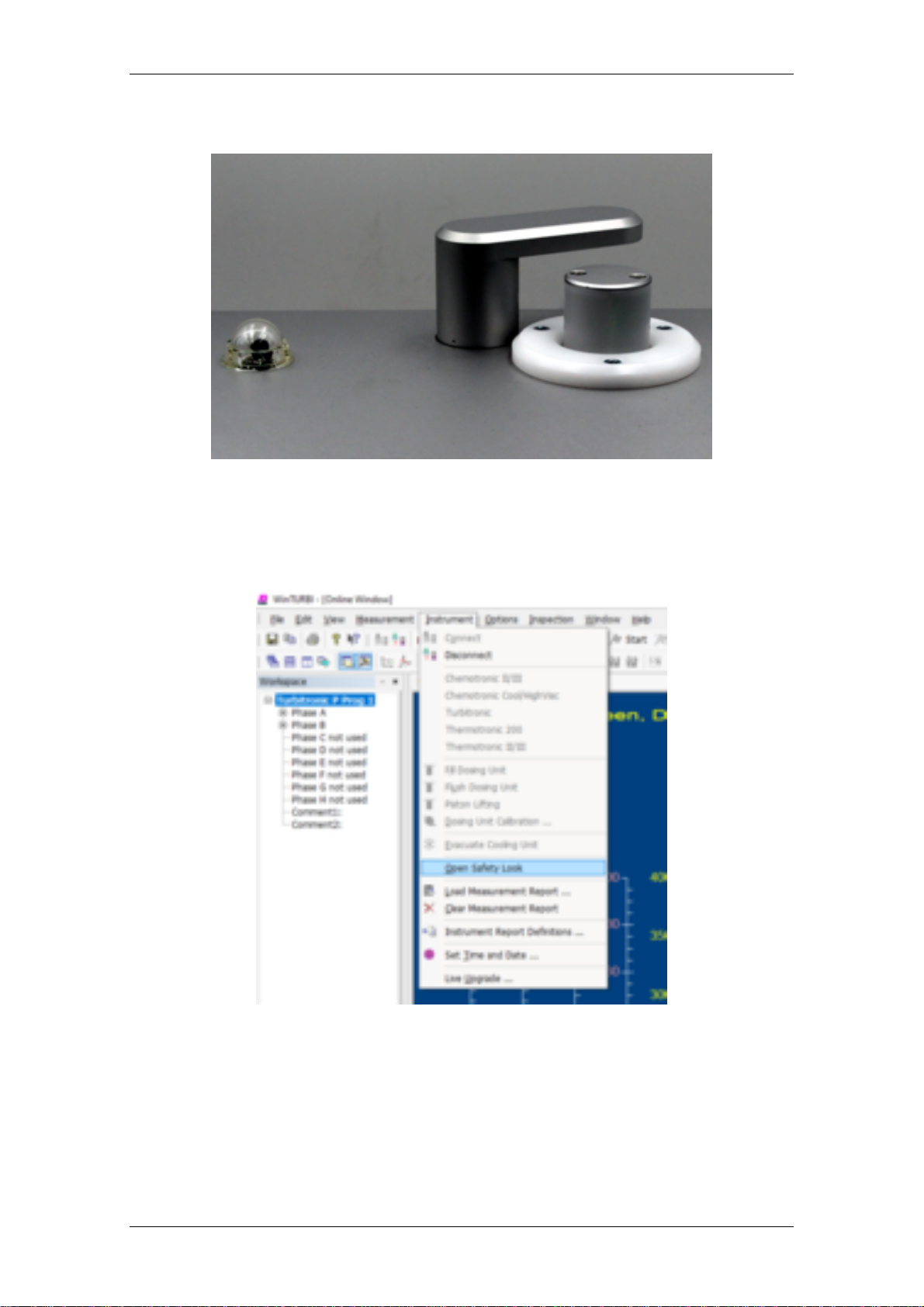

Figure 3 Turbitronic P is realized as UMFT4222PROG USB device

5. Safety Lock – Turbitronic P version

The Turbitronic P measures water based polymers up to temperatures of 150 °C in a pressure

tight samples cell made of glass mainly. During the test the Turbitronic P closes the sample cell

chamber automatically by the safety lock when the samples temperature is higher than 60 °C.

When the temperature decreases 60 °C the sample cell chamber is opened automatically.

Firstly the operator is not being able to remove the hot samples cell under pressure; secondly in

case of unexpected crack the sample cell is kept safely in its fixture.

Before closing the safety lock a red blinks three times. The force of the safety lock is

supervised. In case of a blockage, for example the operator’s finger, it turns back instantly due

to prevent any injury.

Novomatics Manual Turbitronic P

11

Figure 4 Opened Safety Lock

Never try to turn the safety look by hand. It can be damaged. The safety lock can be

opened at higher temperatures on own risk. A warning appears and has to be acknowledged.

Figure 5 Open Safety Lock by operator

Novomatics Manual Turbitronic P

12

6. Principle of temperature measurement

The Turbitronic P determines the sample temperature in direct contact with sample under test. A

pressure tight platinum temperature probe is placed into the glass tube for best thermal

conductivity.

Figure 6 Glass measuring cell with embedded platinum temperature probe

When the sample cell is inserted into the measuring chamber the temperature value is

transmitted wirelessly to the Turbitronic P.

Figure 7 Infrared wireless connection to the instrument

Novomatics Manual Turbitronic P

13

The temperature probe doesn’t require a battery. Its power is supplied by an alternating

electromagnetic field.

Novomatics Manual Turbitronic P

14

7. Starting a first measurement

The preparation of measuring procedure is simple and quick:

1) Place the stirring bar into the glass tube and fill the tube with the sample under test till

lower corner of white rectangle.

2) Close the glass tube by temperature probe

Figure 8 Prepared measuring tube

3) Insert the measuring tube into the instrument

Figure 9 Inserting prepared measuring tube

Novomatics Manual Turbitronic P

15

4) Go to Measurement/Measurement Preparation … and enter the sample name in one of

the comment fields.

Figure 10 Enter the sample name in one of the comment fields

5) Go to Measurement/Turbitronic/Programs P… and check the program settings of your

program, for example P1.

Novomatics Manual Turbitronic P

16

Figure 11 Check the program settings

These are the program standard settings of main parameter; check these according the

settings above.

1) Usage of heating and cooling phase

2) Final temperature 150 °C using a ramp of 10 K/min

3) Stirring speed 240 rpm

6) Check whether the water inlet and outlet hoses are connected correctly and the water

tap is opened for cooling water flow

7) Make sure your program, for example P1, is selected on toolbar and press the Start

button

8) Now the measurement is started.

9) At the end of test the operator is requested to save the measuring file by suggested file

name *.res

Novomatics Manual Turbitronic P

17

8. Program parameter settings

The actual software version supports up to four phases usable for program design. During

program run the phases are processed one by one. A program consists of at least one phase.

Phase Parameter Function

Speed [rpm] The rotational speed of magnetic field that drives

the magnetic bar

Dwell Time [s] Dwell time at target temperature, it starts when

the sample temperature is closer than 0.5 K to

the final temperature

Final Temp [°C] Final temperature or target temperature of that

phase

dT/dt [K/min] Slope of the temperature ramp, when not AFAP

AFAP The final temperature is achieved as fast as

possible

Stop program Defines this phase as the last

General Parameter Function

Zero NTU as calibrated (xxx) Uses pre-calibration of Zero NTU,

recommended for samples which have initial

turbidity at the start of the program,

Refer to

11.5. Zero calibration

for further details

Auto Calib Zero NTU at start Recommend setting for samples which are clear

initially. An auto calibration is performed for Zero

NTU

Automatic CP detection Automatic cloud point detection is for future use

comments To be printed out on cloud point report

(optionally)

Program Select one of eight programs to be edited

Load and Save File Load and Save single programs from and to a

file

Table 1 Program Parameter Settings

Novomatics Manual Turbitronic P

18

9. Reload a measuring file

The WinTurbi software uses a binary format for measuring results.

1) Go to Window/New 2D-diagram.

2) Click the right mouse button, Add Curve …

3) Add the measurement of your choice

4) Modify axes, colors, etc by clicking right mouse button, Content …

10. Stop settings between the measurements

Best practice is to keep the measuring chamber on low temperature between the

measurements. Further starting the stirrer before the next test starts.

Go to Measurement/Turbitronic/Stops Conditions …

Figure 12 Stop Conditions

Novomatics Manual Turbitronic P

19

11. Calibration of relevant parameters

11.1. Temperature calibration

In the Turbitronic P a powerful microprocessor system is installed for the control of all

instrument functions. The wireless temperature probe is used to convert the analogue inputs of

the platinum sensor into a digital signal which is transferred to the Turbitronic P. The wireless

temperature probe uses internal references for long term stability. In case of any error “----“ is

shown on front panel display. A manual calibration is not required.

11.2. Rotation speed calibration

The speed of the magnetic stirring rod in the test tube is controlled by rotation of a strong

permanent magnet. It is driven by a microprocessor controlled motor. The revolving speed is

displayed on front panel. If a stirring speed is set within the Stop Conditions the magnetic

stirring rod turns already before inserted completely into the measuring chamber. This effect

allows the check of stirring function manually.

11.3. Time calibration

Due to the high accuracy of the built-in real time clock, there will be no short term deviations in

the timing functions.

11.4. Turbidity calibration

At start of the test it auto calibration of turbidity is performed, It is assumed the sample has 0

NTU at the start temperature. Further changes in turbidity are related to that. Please make sure

that your sample has really no turbidity at start, if not cool it down till it is completely clear.

The Turbitronic P expresses turbidity in Nephelometric Turbidity Units [NTU]. The value of the

Nephelometric Turbidity Units is calculated by the light transfer through the samples and follows

a non-linear relationship. That’s why the instrument has to be calibrated with three standards.

The Turbitronic P already factory calibrated but the calibration can be approved or re-newed

anytime.

For that purpose prepare three calibration standards according chapter “12. Turbidity calibration

standards” and keep them ready for insertion into the instrument. Please note the three

Novomatics Manual Turbitronic P

20

standards should be inserted without magnetic stirring bar but the tubes should be closed by

temperature probe.

Go to Measurement/Turbitronic/Calib NTU… Insert the three standards 0, 100 and 250 NTU

and press the respective Set button. Release the dialog with OK for taking over the new

calibration. Release with cancel to keep the actual settings valid.

Figure 13 NTU Turbidity Calibration

Figure 14 Samples NTU Turbidity Calibration

11.5. Zero calibration

Zero calibration is required for sample which are already hazy at ambient. Just insert a typical

sample which is definitely clear at room temperature and press the Zero NTU button. Usually

demineralised water is not suitable because its different optical properties compared to typical

This manual suits for next models

1

Table of contents

Other novomatics Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Tektronix

Tektronix RSA306B Installation and safety instructions

Extech Instruments

Extech Instruments HD750-NIST user guide

EPA

EPA LW-MK3 Driver installation

Wolfcraft

Wolfcraft 5210000 Translation of the original operating instructions

PV-Engineering

PV-Engineering PVPM 2540C user manual

Sierra

Sierra Innova-Sonic 205 Quick start instructions