NOVOTEST UT-3K-EMA User manual

EMA Thickness Gauge

NOVOTEST UT-3K-EMA

Postal address and registered address:

51200, Novomoskovsk, Spasskaya Str., 5

Sales office:

landline: +38-056-767-23-25 (multichannel)

mobile: +38-067-565-82-33

http://novotest.ua/

Warranty repair and servicing:

tel. +38-056-767-20-25

Operating manual

Operating manual

EMA Thickness Gauge NOVOTEST UT-3K-EMA

RDC.ED.UT-3K-EMA.000 OM

Page 2

CONTENTS

1 Description and operation of the device and its components.................................................................4

1.1 Intended use ....................................................................................................................................4

1.2 Specification....................................................................................................................................4

1.3 Package ...........................................................................................................................................4

1.4 Configuration..................................................................................................................................4

1.5 Design and operating principle.......................................................................................................5

1.6 Means of measurement, device, and accessories............................................................................5

1.7 Packaging........................................................................................................................................6

2 Intended use ...........................................................................................................................................6

2.1 Operating restrictions......................................................................................................................6

2.2 Preparation of the device for the use...............................................................................................6

2.2.1 Visual inspection......................................................................................................................6

2.2.2 Battery charging.......................................................................................................................6

2.3 Calibration.......................................................................................................................................6

2.4 Operation.........................................................................................................................................7

2.4.1 Thickness measurement...........................................................................................................7

2.4.2 Selection of the amount of coherent integration......................................................................7

2.4.3 Specifics of the operation.........................................................................................................8

2.4.4 Replacement of the probe ........................................................................................................8

3 Safety precautions and warranty............................................................................................................8

3.1 Safety precautions...........................................................................................................................8

3.2 Verification .....................................................................................................................................9

3.2.1 Preconditions for verification...................................................................................................9

3.2.2 Steps of verification and accessories .......................................................................................9

3.2.3 Visual inspection......................................................................................................................9

3.2.4 Testing....................................................................................................................................10

3.2.5 Measurement error calculation...............................................................................................10

3.2.6 Execution of verification........................................................................................................10

3.3 Warranty........................................................................................................................................10

3.3.1 Basic warranty........................................................................................................................10

3.3.2 Warranty on repaired or replaced parts..................................................................................11

3.3.3 Wearing parts.........................................................................................................................11

3.3.4 Owner obligations..................................................................................................................11

3.3.5 Scope of warranty ..................................................................................................................11

3.3.6 Cases uncovered by warranty ................................................................................................12

3.3.7 Warranties and consumer law................................................................................................12

3.4 Maintenance..................................................................................................................................12

4 Running repairs....................................................................................................................................14

5 Storage .................................................................................................................................................14

6 Transportation......................................................................................................................................14

7 Disposal................................................................................................................................................14

Operating manual

EMA Thickness Gauge NOVOTEST UT-3K-EMA

RDC.ED.UT-3K-EMA.000 OM

Page 3

Caution!

Please read this manual carefully before using EMA Thickness Gauge NOVOTEST UT-3K-EMA.

Operating manual (hereinafter referred to as OM) includes the information required to inform

operator about the performance and operating procedure of the device –EMA Thickness Gauge

NOVOTEST UT-3K-EMA (hereinafter referred to as device or thickness gauge). The document

contains the specification, description of the design and operating principle, as well as the information

necessary for the right product operation. Before using the device, you must read this manual, as the

device must be operated by persons acquainted with the operating principle design of the device.

The right and efficient use of the device requires:

measurement technique;

conditions of measurement that correspond to the measurement technique;

a trained operator who read this operating manual.

NOVOTEST reserves the right to make minor changes that do not impair the technical

specification of the product. These changes may not be mentioned in this document.

The delivery set of the device includes the operation documents that are a part of this manual and

the device registration certificate.

This OM applies to all product modifications.

Operating manual

EMA Thickness Gauge NOVOTEST UT-3K-EMA

RDC.ED.UT-3K-EMA.000 OM

Page 4

1 DESCRIPTION AND OPERATION OF THE DEVICE AND ITS COMPONENTS

1.1 Intended use

EMA Thickness Gauge NOVOTEST UT-3K-EMA is intended for measuring the wall thickness of

steel pipes, rolled sheets, rods and other steel products, as well as aluminum and other metals, without

the use of couplant and preliminary surface preparation, with a working gap between the probe and

metal of up to 2 mm. The gap might be a layer of rust, a layer of salt deposits or another non-

conductive coating (paint, varnish, enamel, plastic, etc.).

The thickness gauge works both independently and connectively to an Android-based tablet and

displays the real-time radio signal on the screen in the thickness gauge of flaw detector mode (А-scan).

1.2 Specification

The technical specifications of the device are given in the tab. 1.1.

Table 1.1 –Principal specifications of the device

Measurement range for steel, mm

260

Thickness measurement error, mm

0,08

The permissible gap between the probe and the test object, mm, max

2

The permissible deviation of the probe from the normal to the

surface of the test object,

25

The minimum permissible radius of curvature of the test surface, mm

10

Maximum number of measurements per second

16

Ultrasound velocity range

10009999 m/s,

with 1 m/s increment

Frequency range

35 MHz

Worktime without charging, h

5

Operating temperature, С

from -20 to +50

Dimensions, mm

163х39х32

1.3 Package

The electronic unit of thickness gauge with probe ................................................................1 pc.

Charger....................................................................................................................................1 pc.

Transportation case.................................................................................................................1 pc.

Operating manual RDC.ED. UT-3K-EMA.000 OM..............................................................1 pc.

Registration certificate RDC.ED.UT-3K-EMA.000 PS .........................................................1 pc.

* By a customer request, additional equipment or parts can be included in the package. The exact

information on the scope of delivery is indicated in the device certificate.

1.4 Configuration

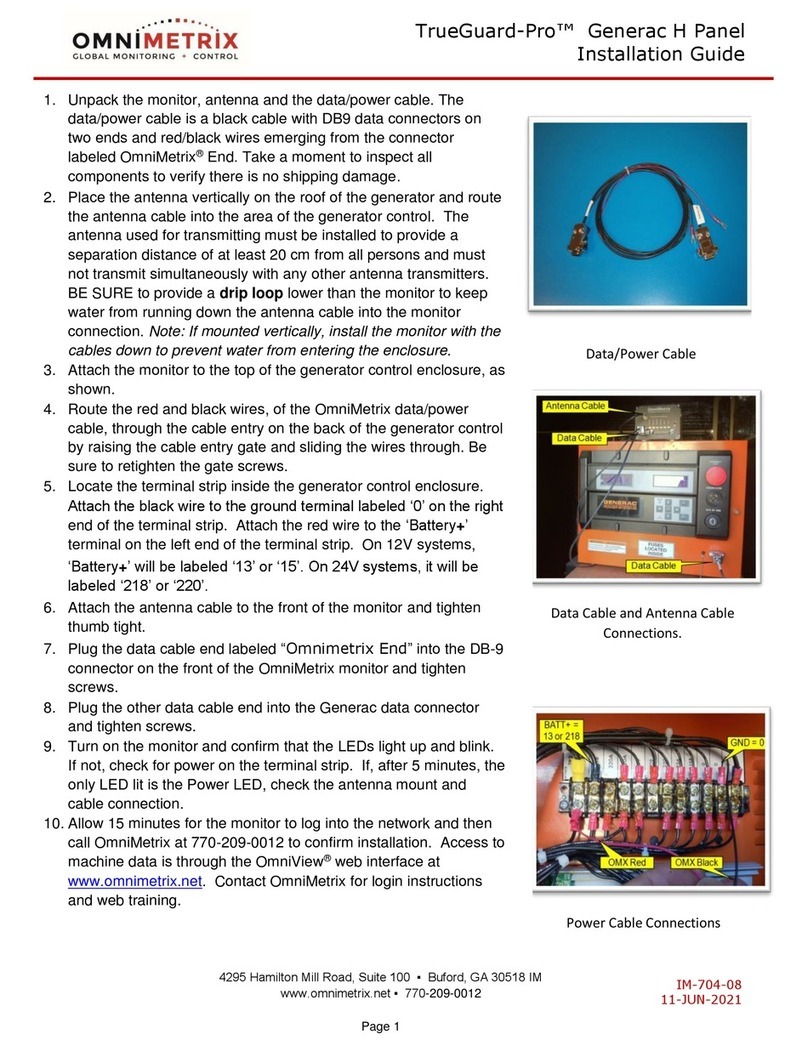

The device is enclosed in a plastic casing with a removable probe in the front part (fig. 1.1).

Operating manual

EMA Thickness Gauge NOVOTEST UT-3K-EMA

RDC.ED.UT-3K-EMA.000 OM

Page 5

1 –probe; 2 –digital display; 3 –power button;

4 –calibration button; 5 –“Up” button; 6 –“Down” button; 7 –mini-USB connector.

Figure 1.1 –EMA Thickness Gauge NOVOTEST UT-3K-EMA

The device is equipped with a digital display to show the readings. The buttons located to the right

side of the display perform the following functions:

“OK” button – switching the device on and off, navigation through the menu;

“Calibration” button, entering the menu;

“Up” button –increasing the parameter value;

“Down” button – decreasing the parameter value.

The mini-USB socket is designed for connection of charger and connection of outer devices such

as an Android-based tablet or a smartphone.

1.5 Design and operating principle

The device operation is based on the measurement of the time of flight of the acoustic wave

through the tested material. The measured time is recalculated into the thickness value by the preset

ultrasound velocity value.

The acoustic wave is formed by electromagnetic acoustic transduction directly on the surface of

the test object and avoiding the contact media between probe and test object. Thanks to this, the wave

is not disrupted in this media. The testing gap can be 2-3 mm and might be in the form of air, liquid,

rust, paint, plastics, etc.

The special data processing algorithm allows correct measuring of the thickness of the test object

in the presence of interfering factors, such as metal anisotropy, the presence of several reflectors, and

the presence of external interference. The device allows eliminating the human factor completely and

making measurement fully automatic.

1.6 Means of measurement, device, and accessories

The device operability must be checked with the reference block included in the package.

In normal operating conditions, the indicated value of the device must correspond to the value of

the reference block. If the readings are wrong, the device must be calibrated according to the c. 2.3.

Operating manual

EMA Thickness Gauge NOVOTEST UT-3K-EMA

RDC.ED.UT-3K-EMA.000 OM

Page 6

If any malfunction is found, the adjustment and setting of the device must be done by

NOVOTEST.

1.7 Packaging

The device and its components are shipped in a case to avoid possible damage during

transportation.

2 INTENDED USE

2.1 Operating restrictions

The device must be used with consideration of environmental factors and characteristics of test

objects and in line with the specified technical specifications, as well as the own technical

specifications.

The device must be used only by users acquainted with the operating manual.

If the device is transported at sub-zero temperature and operated at the temperature above zero, it

should be kept in a package for at least 2 hours to avoid malfunctioning due to moisture condensation.

2.2 Preparation of the device for the use

2.2.1 Visual inspection

Before using the device, inspect the device carefully and make sure that it is not damaged.

2.2.2 Battery charging

If the battery is discharged, the device must be charged via the charger. If the battery charge is less

than 25%, the device readings will flash on and off. When the charger is connected to the device, the

display shows the level of the battery charge.

In order to check the battery charge level, do the following:

1.

Turn the device on by pressing “ ”;

2.

Press “ ” or “ ”, and the letter “В” will appear on the display and three figures

indicating the battery charge level.

For example: “В025” –the battery is discharged by 25 %.

Charging the battery completely takes at least two hours. The device is recommended to charge

with the power off.

Caution!

If the device battery is fully discharged for a long time, this can reduce the battery capacity and service

life. If the battery is fully discharged, it is advised to charge it as soon as possible. This requirement

must be fulfilled during the long-term storage of the device.

2.3 Calibration

The device features two calibration methods: by the known test object thickness and known sound

velocity.

2.3.1 Calibration by the known thickness:

1. Turn the device on by pressing “ ”.

2. Install the device on the test object with the known thickness.

3.

Start calibration by pressing “ ”. The readings will start flashing.

4.

Set the known thickness value of the reference block by pressing “ ” or “ ”.

Operating manual

EMA Thickness Gauge NOVOTEST UT-3K-EMA

RDC.ED.UT-3K-EMA.000 OM

Page 7

Note –Holding “ ” or “ ” button will change the increment of the value.

5.

Press “ ”.

2.3.2 Calibration by the known ultrasound velocity:

1. Turn the device by pressing “ ”.

2. Press “ ” twice. The figures on the indicator will start flashing.

3. Set the known ultrasound velocity using “” or “ ”.

Note –Holding “ ” or “ ” button will change the increment of the value setting.

4. Press “ ”.

Caution!

The device employs a transversal wave. The typical value of transversal wave propagation in steel is

3250 m/s.

2.4 Operation

2.4.1 Thickness measurement

To perform the thickness measurement, take the following steps:

1. Turn the device on by pressing “ ”. If there is no object near the probe, the thickness values

on the device display will change randomly.

2. Calibrate the device if it is necessary, according to c. 2.3.

3. Place the device on the surface of the test object. The device will display the thickness value

within a period from 100 milliseconds to 3 seconds, depending on the selected amount of

integration.

2.4.2 Selection of the amount of coherent integration

The device can measure the thickness using the coherent integration algorithm that allows

increasing signal/noise ratio and improves the accuracy of thickness measurement.

When the device is issued with a big gap for the objects with poor quality of the surface, it is

recommended to increase the amount of integration to improve the measurement accuracy.

To change the amount of integration, take the following steps:

1. Turn the device on by pressing “ ”.

2. Press “ ” three times. The display will show A0XX inscription, where

ХХ –the amount of integration.

3. Set the needed amount of integration with “ ” or “ ” button.

The amount of integration can be: 16, 32, 64, 128, 256, 512, 1024.

Operating manual

EMA Thickness Gauge NOVOTEST UT-3K-EMA

RDC.ED.UT-3K-EMA.000 OM

Page 8

4. Press “ ” button.

It should be noted that the measurement time increases with the increase of the amount of

integration. By default, 32 integrations are set in the device.

2.4.3 Specifics of the operation

The probe contains the permanent magnet which implies specific requirements to the device

operation:

1. If the device is moved near a knife, fork, needle, and other sharp metal objects, operator should

exercise care. Such objects may get magnetized to the probe housing and harm operator. To

avoid this, operator should hold the device should by the middle and rear part, as far from the

probe as possible.

Note –If the device is placed in proximity of a plastic magnet card, this might lead to failure of

the card.

2. If the device is placed on a loose and relatively lightweight sample, operator should hold it with

hand.

3. If operator puts the device on a test object quickly and carelessly, it might bump against due to

additional acceleration caused by the magnetic field. To save the service life of the probe, it is

recommended to place the device on a test object smoothly and hold the device meanwhile.

4. It is recommended to put the device on the test object at a 60angle. Once the probe touches the

test object, the device should be put upright.

Throughout the device operation, operator should check the integrity of the plastic protector of the

probe. If plastic protector is damaged and the emitting coil is opened, the probe should be replaced.

Caution!

If the device is used with the probe damaged, this may lead to device failure. When the damaged probe

(and exposed coil wires) contacts metal, this may lead to sparkling.

2.4.4 Replacement of the probe

If the plastic coating of the probe is worn, the probe should be replaced.

The probe can be replaced at the NOVOTEST service center, or operator can do it individually.

To replace the probe of the probe, take the following steps:

1) Unscrew four screws holding the probe on the body;

2) Remove the damaged probe;

3) Put the new probe into the body;

4) Fix it with screws.

3 SAFETY PRECAUTIONS AND WARRANTY

3.1 Safety precautions

After commissioning of the device, it is recommended to inspect it periodically to check the

following:

operability;

compliance with the operating requirements;

absence of damage to the device components.

The device shall be operated by persons instructed and certified under ІІ qualification category by

safety guidelines when using electrical measuring devices.

Operating manual

EMA Thickness Gauge NOVOTEST UT-3K-EMA

RDC.ED.UT-3K-EMA.000 OM

Page 9

3.2 Verification

Once the device is commissioned, its primary verification must be done. Periodic verification

should be done during the use of the device and after its repair. It is recommended to verify the device

at least once a year.

The method of verification, hereinafter referred to as verification, applies to EMA Thickness

Gauge NOVOTEST UT-3K-EMA and prescribes the methods and means of primary and periodic

checking.

The device verification must be done by State Metrology Service or other authorized bodies and

organizations having the right of verification.

3.2.1 Preconditions for verification

The following requirements must be fuilfilled at the verification:

–ambient air temperature: from +5оС to +30 оС;

–relative air humidity: max 80% at the temperature +25 С;

–air pressure: from 86 kPa to 106 kPa.

3.2.2 Steps of the verification and accessories

When performing the verification, take the following steps and use accessories specified in Tab.

3.1.

Table 3.1 –Steps of the verification and accessories

Verification steps

Clause

Verification accessories

Necessity after

commissioning

and repair

operation and

storage

1. Visual inspection

3.2.3

Yes

Yes

2. Verification

3.2.4

Yes

Yes

3. Determination of

the measurement error

3.2.5

Set of ultrasonic thickness reference

blocks KUSOT-180 or the set of

thickness reference blocks KMT-

176M-1 (KMTC-97);

set of plane-parallel blocks (tab. 3.2).

Yes

Yes

4. Execution of

verification

3.2.6

Yes

Yes

Table 3.2 –Parameters of plane-parallel reference blocks made of the same steel sample.

Thickness, mm

Roughness RZ, mcm, less

2 ± 0,01

10

10 ± 0,015

20

60 ± 0,03

20

3.2.3 Visual inspection

The device must be equipped according to c. 1.3 of Operating manual of EMA Thickness Gauge

NOVOTEST UT-3K-EMA.

Operating manual

EMA Thickness Gauge NOVOTEST UT-3K-EMA

RDC.ED.UT-3K-EMA.000 OM

Page 10

Probe and connection cable should be checked visually, the insulation and labels must be free of

damage. The connectors should be clean, and there must be no disconnected or loose elements (device

should be shaken to check, and the connector of the probe must tightly sit in the slot of the electronic

unit.

3.2.4 Testing

The device must be prepared for operation under c. 2.2 of Operating manual of EMA Thickness

Gauge NOVOTEST UT-3K-EMA.

To check the operability, take the following steps:

1. Calibrate the device using a reference block;

2. Measure the thickness of the reference block. The thickness value of the reference block

should be different from the actual meaning (10 mm) by more than 0.04 mm.

3.2.5 Measurement error calculation

Measurement error is calculated using the set of blocks made of the same billet as follows:

1. Put device should be put on the 2 mm reference block;

2. Calibrate the device using the known thickness of the test object;

3. Make 5 measurements of thickness in five different points of 2 mm reference block;

4. Define the maximum measurement error ∆ by the formula:

∆= max(Hi–Hо)

where Нi–measured value; Но–thickness of reference block;

5. Repeat steps in clauses 1 –4 for 10 and 60 mm reference blocks.

Verification is considered acceptable if the measurement error of the device for all reference

blocks is not more than ± 0,04 mm.

3.2.6 Execution of verification

The verification of the device recognized operational shall be executed by a verification certificate

of the approved form and stamping.

The failure of verification is executed by a certificate of inoperability with the reason and

cancellation of certification of the previous verification.

3.3 Warranty

The warranty covers all NOVOTEST products.

NOVOTEST warrants the compliance of the device with the technical regulations provided that

operator fulfill the requirements to the transportation, storage, and operation, and performs timely

service maintenance at the NOVOTEST facility at least once a year.

3.3.1 Basic warranty

Your new NOVOTEST device purchased from NOVOTEST or the authorized dealer is covered

by the 1-year basic warranty.

If any component of the device fails due to a defect in material or workmanship, it shall be

repaired free of charge or replaced by NOVOTEST or by an authorized dealer of NOVOTEST,

regardless of transfer of the right of ownership of the device during the warranty period.

The warranty on batteries and chargers is provided directly by manufacturers of batteries and

chargers, so they are not covered by NOVOTEST warranty. However, your authorized dealer of

NOVOTEST will assist you in making warranty claims regarding batteries and chargers.

Operating manual

EMA Thickness Gauge NOVOTEST UT-3K-EMA

RDC.ED.UT-3K-EMA.000 OM

Page 11

The warranty on the device starts from the date of purchase of the device, usually from the

shipment of the device to the customer. If the device is acquired by an intermediary company, the

warranty period shall start upon the transfer of the device to an intermediary company.

3.3.2 Warranty on repaired or replaced parts

All branded parts of NOVOTEST installed during the warranty service are covered by the

NOVOTEST warranty (up to the end of warranty period).

The spare parts replaced during the warranty service shall not be returned to the device owner.

3.3.3 Wearing parts

The components worn during the device operation fall into two main categories. The first category

includes the parts that require replacement or adjustment with a frequency stipulated by the device

maintenance schedule, and the second category includes the wearing parts whose replacement or

adjustment frequency depends on the operating conditions of the device.

The parts listed below either have a limited life or may require replacement (adjustment) due to

damage. However, the following parts are covered by the 12-month basic warranty of NOVOTEST:

probes and their components;

connecting cables;

parts and mechanisms exposed to mechanical impact during operation.

Note: The parts worn due to friction (such as knives, cutters, movable parts of measuring probes,

ultrasonic piezoelectric probes, support rings, etc.) are not covered by NOVOTEST basic warranty of

these parts fail due to wear and tear during the device operation. However, if these parts fail during

the warranty period due to a defect in material or workmanship, they will be repaired or replaced

under the basic warranty.

3.3.4 Owner obligations

The operating manual and registration certificate of the device specifies the information about the

proper operation and maintenance of your device.

A proper operation and maintenance of the device will help you avoid costly repairs caused by

incorrect operation, negligence or improper maintenance. In addition, following our recommendations

will extend the service life of the device. Therefore, the device owner should:

If any defect or fault is found, submit the device to NOVOTEST or authorized dealer of

NOVOTEST for a warranty repair as soon as possible. This can minimize the repair

required for your device.

Use only branded spare parts and couplants of NOVOTEST (with appropriate labels)

during the device maintenance.

Make records of the device maintenance in the registration certificate and keep receipts

and bills. If necessary, they will prove that the maintenance was made in time (according

to periodicity specified in the registration certificate), using the recommended spare parts

and couplants. This will help you in making warranty claims to defects that might occur

due to a deviation from the device maintenance schedule or the use of unauthorized parts

or materials.

Clean the casing of the device and probe according to recommendations of NOVOTEST.

Fulfill the operation and storage requirements of devices in line with NOVOTEST

recommendations.

3.3.5 Scope of warranty

The NOVOTEST warranty shall not apply if a repair or replacement of parts was caused by one of

the following factors (in the absence of manufacturing defects):

Operating manual

EMA Thickness Gauge NOVOTEST UT-3K-EMA

RDC.ED.UT-3K-EMA.000 OM

Page 12

Damages caused by negligent/incorrect operation of the device, natural disaster, water

intrusion into device, probe, accessories, and parts of the device, accident or misuse of the

device;

Wear and tear of parts;

Non-observance of NOVOTEST recommendations regarding periodicity of the device

maintenance;

Non-observance of requirements to the device operation recommended by NOVOTEST;

Changing of the configuration of the device or its components, intrusion into systems of

the device, etc. without the approval of NOVOTEST;

Use of inappropriate batteries and accessories;

Changing of power supply in the grid;

Refusal from repair of any damages found during the regular maintenance;

Factors outside the scope of control of NOVOTEST, for example, air pollution, hurricanes,

chips resulting from shocks, scratches, and use of unsuitable cleaning fluids;

Use of the repair methods not approved by NOVOTEST;

Use of third-party spare parts and couplants of NOVOTEST.

All repairs covered by the NOVOTEST warranty shall be performed by the authorized service

center of NOVOTEST.

3.3.6 Cases uncovered by warranty

The basic warranty of NOVOTEST and extended warranty of NOVOTEST shall not hold

NOVOTEST accountable for any unexpected or indirect damage resulting from a defect covered by

the above warranties. Such damage includes (but is not limited to the following):

reimbursement for inconveniences, phone calls, posting and shipping expenses the device,

loss of profit or damage to property;

all warranties shall become void if the device is officially recognized unserviceable.

3.3.7 Warranties and consumer law

The basic warranty of NOVOTEST and extended warranty of NOVOTEST shall not harm your

rights provided by the sale agreement that is executed with selling the device to the manufacturer or

authorized dealer of NOVOTEST; and the applicable law stipulating the requirements to sales and

servicing of consumer goods.

3.4 Maintenance

The information about the maintenance applies to all NOVOTEST products.

The maintenance shall be performed during the device operation and is categorized into:

preventive maintenance;

regular maintenance.

Preventive maintenance shall be performed at least once in a quarter and includes visual

inspection, cleaning, and greasing.

Regular maintenance shall be performed by NOVOTEST at least once a year and is mandatory to

save the warranty of NOVOTEST.

It is very important to maintain the device during the entire operation period.

The list of steps performed during each maintenance will depend on the device model, year of

production, and run to failure. By your request, the authorized service center of NOVOTEST may

provide you the information about steps to be taken when servicing the device.

The records of regular maintenance of your device shall be made in the registration certificate of

the device. The information about maintenance is very important; it can be needed to exercise your

rights for warranty repair of the device. So, always make sure that the authorized service center of

NOVOTEST puts a stamp in the right place under the record about the performed procedure.

Operating manual

EMA Thickness Gauge NOVOTEST UT-3K-EMA

RDC.ED.UT-3K-EMA.000 OM

Page 13

If any failure in the device is found, it shall be submitted to NOVOTEST for maintenance. The

table 3.3 lists the failures that operator can eliminate individually.

Operating manual

EMA Thickness Gauge NOVOTEST UT-3K-EMA

RDC.ED.UT-3K-EMA.000 OM

Page 14

Table 3.3 –Possible failures and methods of elimination

Name of failure, signs, and

additional evidence

Possible reason

Method of elimination

No digits on the display after

turning on

The battery is fully discharged

Charge the battery

When checking the performance

of the thickness gauge on a

reference block, the

measurement error is bigger than

the permissible error

The device is not calibrated

Set and calibrate the device

under c. 2.3 or c. 2.5.4.3 of

RDC.ED.UT-3K-

EMA.000.OM.

Operating manual

EMA Thickness Gauge NOVOTEST UT-3K-EMA

RDC.ED.UT-3K-EMA.000 OM

Page 15

4 RUNNING REPAIRS

By design and operating conditions, the device belongs to the devices that should be repaired by

specialized companies or a manufacturer.

To submit the device to the service center (SC) for warranty service, the registration certificate of

the device must be submitted. SC shall make a record in the registration certificate about the warranty

service of the device and sends the copy to the manufacturer.

The device shall be submitted for warranty (after-warranty) repair or verification along with the

registration certificate of the device. The accompanying documents shall state the contact details,

phone number, and fax of the sender, and the method and address of delivery.

The warranty repair is performed upon the presence of the filled in registration certificate.

5 STORAGE

The storage conditions of the device belong to category 1 according to GOST 15150 at the

ambient temperature from +5 °С to +40 °С and relative humidity up to 80 % at the temperature of 25

°С. During short-term storage and in the periods between applications, the device shall be stored in the

intended packaging container. The place of storage should be free from vapors of aggressive media

(acids, alkali) and direct sunlight. The device shall not be exposed to rapid shocks, falls or strong

vibrations.

The devices shall be placed on storage racks or in palletized in the transportation container.

For a long-term storage, the device must be preserved.

6 TRANSPORTATION

The packed devices can be transported by any kind of carrier upon the fulfilment of the following

requirements:

transportation is performed in the factory container;

no direct moisture influence;

the temperature does not go outside the range from -50 °С to +50 °С;

humidity does not exceed 95 % at the temperature up to 35 °С;

vibration is in the range 10-500 Hz with an amplitude up to 0.35 mm and acceleration up to 49

m/c2;

shocks of peak acceleration of up to 98 m/s2;

the devices in the vehicle are fastened to avoid falling and mutual bumps.

To avoid the moisture buildup inside the device after transportation from the sub-zero

environment to a warm place, the device should be held in a container for 6 hours at room temperature.

7 DISPOSAL

The device does not contain dangerous or harmful substances that could harm a human health or

environment and are not dangerous for life, public health and environment upon expiration of the

service life. Due to this fact, device disposal can be done according to common waste disposal

practice. Disposal shall be done by the type of components: plastic, metal, and fastening components.

The content of precious metals in the device components (electronic boards, connectors, etc.) is

very low, so recycling is not expedient.

Operating manual

EMA Thickness Gauge NOVOTEST UT-3K-EMA

RDC.ED.UT-3K-EMA.000 OM

Page 16

Notes

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

Table of contents

Other NOVOTEST Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

AW

AW 200 Operator's manual

Shaw

Shaw SADP operating instructions

Badger Meter

Badger Meter Blancett QuickSert B131C-038 user manual

Spectro-UV

Spectro-UV Spectroline AccuPRO XP-4000 Operator's manual

Bühler technologies

Bühler technologies BCI 24-D Series Brief instructions

OmniMetrix

OmniMetrix TrueGuard-Pro installation guide