8

5.MODEL DC80L

The DC80L is the calibrator model for measuring and simulating V, mV and mA

signals. The DC80L is capable of measuring and generating 0 to 24 mA DC

current signals and voltages up to 15 V DC. Simultaneous measurement and

signal simulation is not provided.

Current measurements options are:

-With use of external power supply provided by the system. In this case, the

calibrator is placed in series to measure the loop current (signal of a 2-wire

transmitter, for example).

-The calibrator provides the power to the loop. This option makes use of the

DC80L built-in power supply. This configuration applies to measurements of

standalone 4-20 mA transmitters (sink type transmitters).

Current simulation possibilities are:

-The calibrator sources the current to the target instrument.

-The calibrator simulates (behaves as) a 2-wire transmitter.

The following tables show the DC80L specifications functions and ranges, based

on a one year calibration period, at ambient temperatures ranging from +18 °C to

+28 °C. “Counts” means units of the least significant digit.

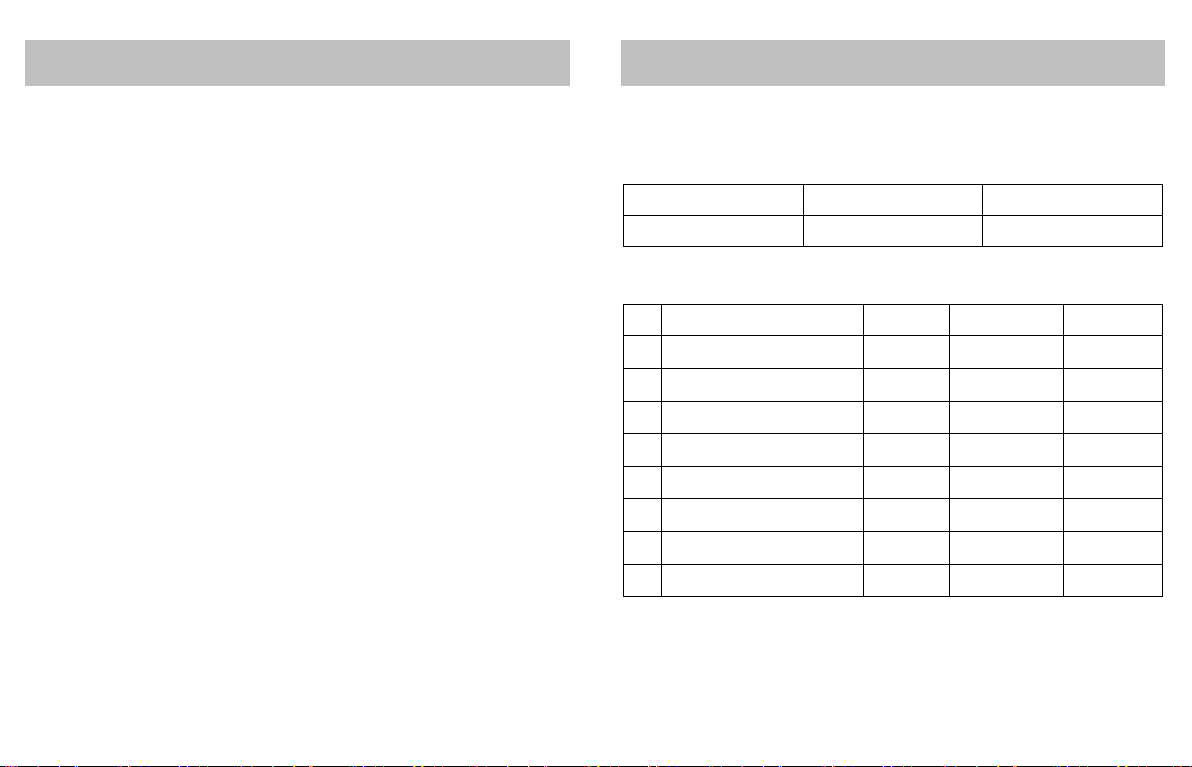

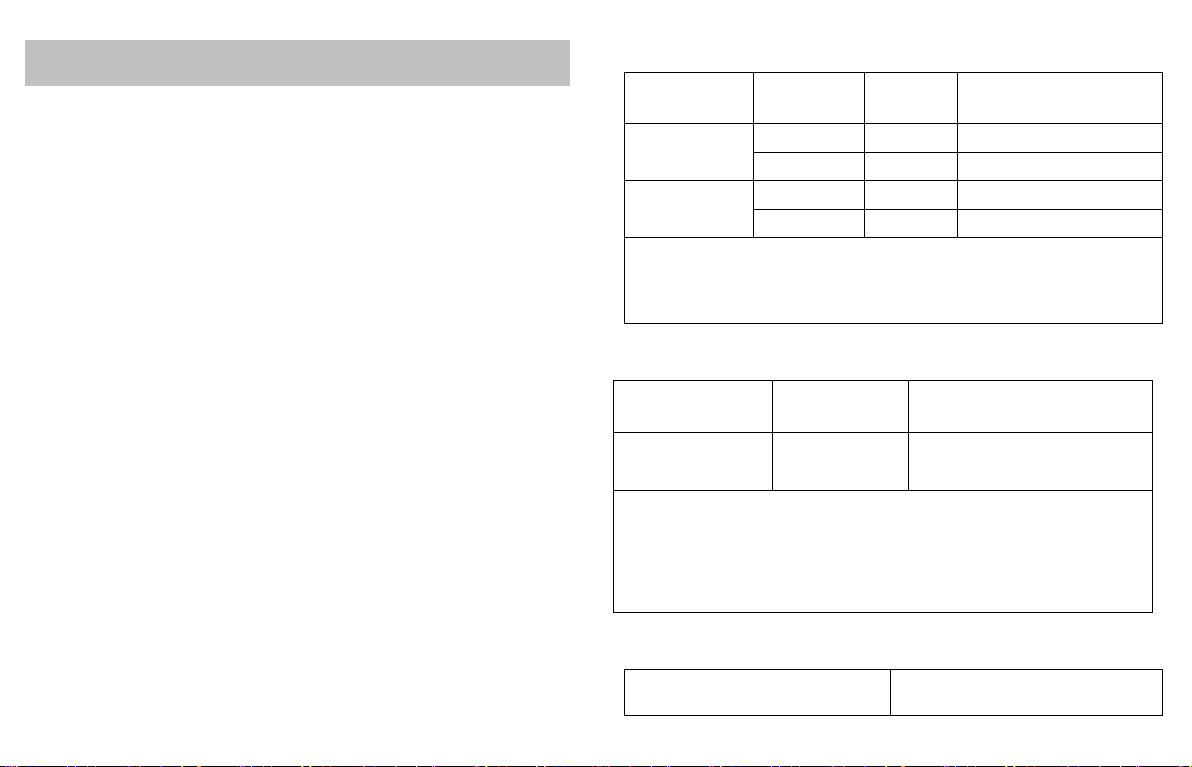

Voltage measurement and simulation:

Function Range Resolution Accuracy ± (% of reading +

Counts)

DC V / mV INPUT

Auto range 0 ~ 110 mV 0.01 mV ± (0.05 % + 5 counts)

0 ~ 15 V 0.001V ± (0.05 % + 5 counts)

DC V / mV

OUTPUT

0 ~ 100 mV 0.01 mV ± (0.05 % + 5 counts)

0 ~ 15 V 0.001V ± (0.05 % + 5 counts)

Input impedance: 2 M Ω(nominal) < 100 pF

Over voltage protection: 30 V

Voltage driver capability: 1 mA

DC mA measurement and simulation

Range Resolution Accuracy @ 25 °C

± (% of reading + Counts)

0 ~ 24 mA

(Inputand Output) 0.001 mA ± 0.03% + 5

Overloadprotection: 125 mA, 250 V fast acting fuse

Percent display: 0 % = 4 mA, 100 % = 20 mA

Sourcemode: compliance 1000 Ω at 20 mA for battery voltage ≥ 6.8 V (700 Ω

at 20 mA for battery voltage5.8 to 6.8 V )

Simulatemode: Externalloopvoltagerequirement:24V nominal,30 Vmax, 12Vmin

Loop Power

Internal power supply 24 V ± 10 % / 25 mA max.