NoxBox NOxBOXi User manual

NOxBOXiOperating Instructions

®

1

www.noxboxltd.com

Bedfont Scientic Ltd, Station Road, Harrietsham, Maidstone, Kent, ME17 1JA

Issue 6.0 (Software V.17.1) September 2015. Part No: LAB636

© NOxBOX Ltd NOxBOX Limited reserves the right to change or update this literature without prior notice. Registered ofce: England and Wales. Registered No: 9563860

ISO 9001:2008

Cert No. FM 31664

ISO 13485:2003

Cert No. MD 502905

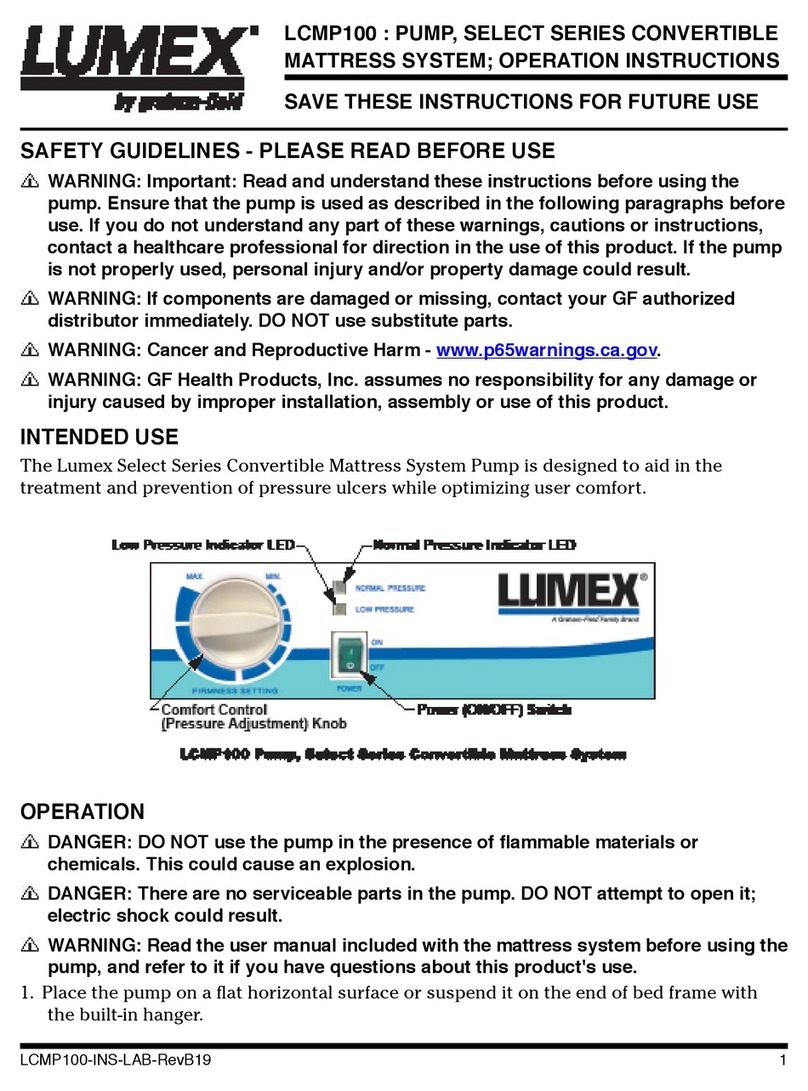

Set- Up

Before you use the Bedfont NOxBOXiintelligent Nitric Oxide delivery and monitoring system it is important to follow these steps:

Ensure the device does not require maintenance (monthly) and that the maintenance is not due during the expected duration of the therapy such as:

• NO sensor high calibration

• NO2 sensor high calibration

• Pump calibration

• Vent calibration

Checklist

• Ensure the device is clean and free from damage

• Ensure the water trap is empty and has been cleaned from previous use

• Ensure all single use items from previous patient have been discarded

Equipment you will need for set-up:

• A NOxBOxi system test kit (NOXBOX-I TEST)

• A NOXKIT (inspiratory limb size dependant)

• Two cylinders of delivery gas

• A 22mm one-way valve for HFO ventilator circuits (FXS555)

Additional items

• NOxAIR Environmental monitors

• Manual bagging kit

NOTE: If you do not have the parts listed above or the device has not been maintained the NOxBOXimay not be suitable for use and you may be unable to

set-up the device. Failure to follow these procedures may result in harm to to the operator or the patient.

NOxBOXiOperating Instructions

®

2

www.noxboxltd.com

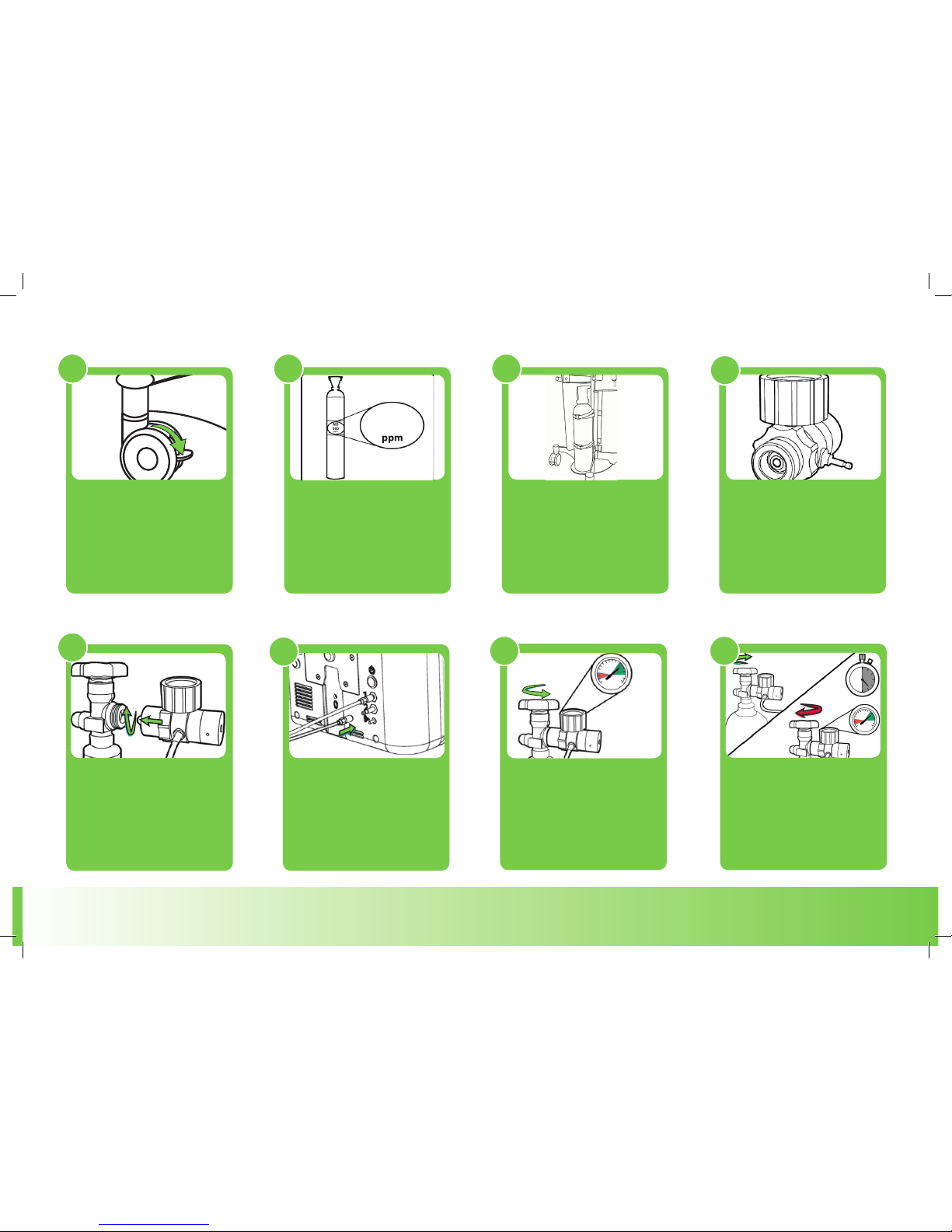

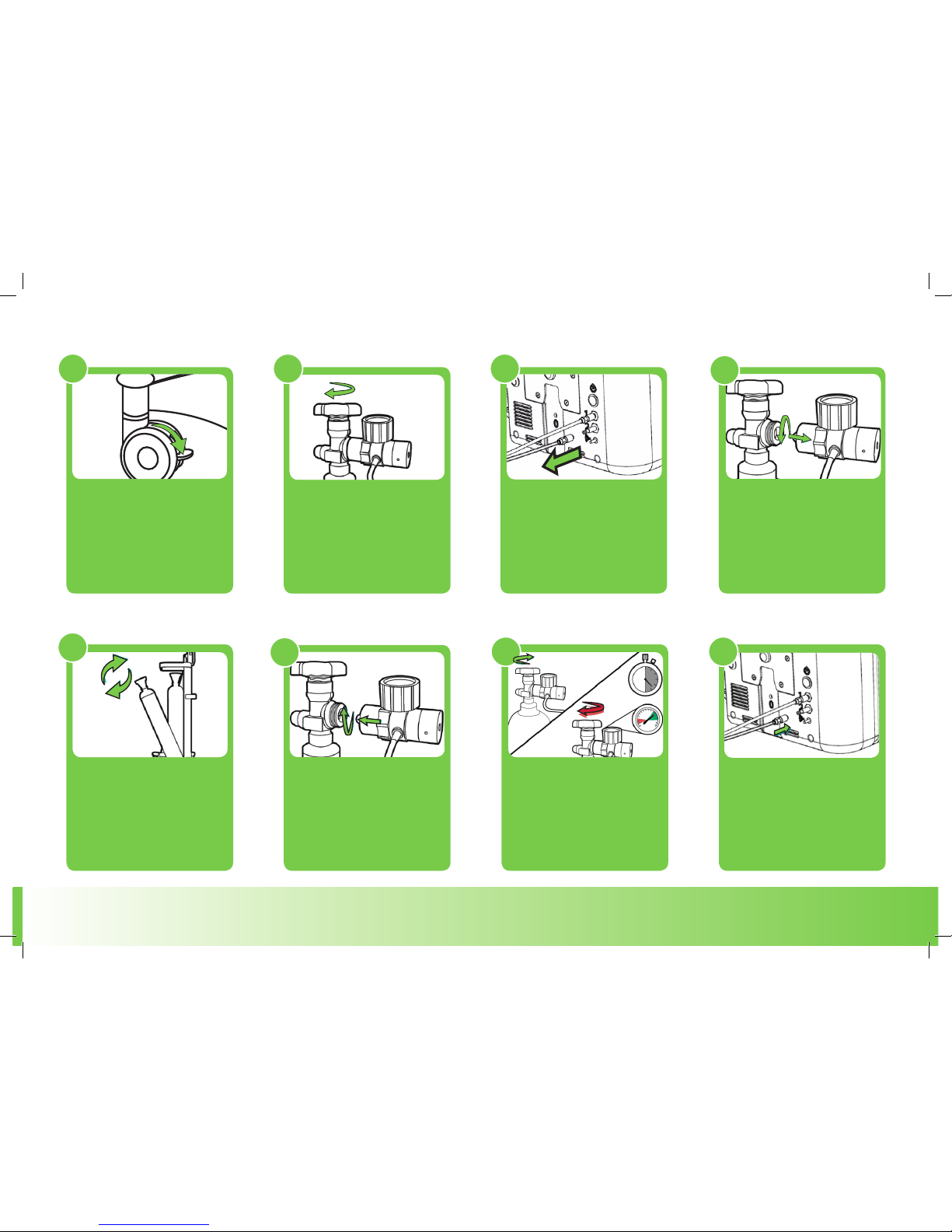

Setup

Engage trolley brakes to

stabilise system prior to use.

To attach monitor to trolley,

carefully drop the monitor

over the attachment plate.

Connect power supply to

suitable rated mains outlet.

Press power button to start

system.

Once zero test is complete,

follow instructions on

screen to set-up system.

Experienced users may

choose to skip directly to

system tests or skip to dose.

System test circuit set-up:

NOxFlowTM arrow points in

direction of ow. 1m vent

tubing between sample

point and NOxFlowTM.

Perform system

test to ensure correct system

functionality prior to

connecting to patient.

Connect to patient circuit;

sample near patient Y-piece.

Retain NOxFlowTM

orientation for ow and 1m

distance from sample point.

1 2 34

56 7 8

NOxBOXiOperating Instructions

®

3

www.noxboxltd.com

Performaleaktest:openthe

cylindervalvethenclose.

Observegaugefor30

seconds,needleshould

remainsta>onary.

Engage trolley brakes to

stabilise system prior to

changing cylinder.

Check cylinder concentration

matches the setting for the

system.

Check regulator surfaces and

O rings are damage free. Do

not use damaged equipment.

Attach regulator to cylinder.

Screw rmly by hand. Attach

supply line to regulator.

Apply supply line to port on rear

of monitor

12 3

5

Slowly open cylinder valve.

Read gauge. If needle in red

zone, replace cylinder before

starting treatment.

Perform a leak test: open the

cylinder valve then close.

Observe gauge for 30

seconds, needle should

remain stationary.

4

68

Cylinder setup

7

Load cylinders onto trolley.

Secure with straps.

1000

NOxBOXiOperating Instructions

®

4

www.noxboxltd.com

System tests

System test circuit set-up:

NOxFlow arrow points in

direction of ow. 1m vent

tubing between sample

point and NOxFlow.

Re-open NO cylinder.

Connect O2supply to

NOxFlowTM inlet. Set O2 ow

to 10 L/min. Press“Next” on

system screen to run test.

System test takes approx.

5 minutes to run. This purges

NO2and ensures correct

NOxBOXioperation.

System test passed. Stop O2 ow

and disconnect from NOxow.

Ready to connect to patient.

System test failed. Check:

NOxFlow orientation; O2

ow at 10 L/min, NO cylinder

connected and valve open.

Re-run test.

If not using in next 10 mins: Unit

may time out and may require

you to repeat step 4.

Connect to patient circuit.

Enter dose and check alarm

levels before commencing

treatment.

123

4567

NOxBOXiOperating Instructions

®

5

www.noxboxltd.com

Ventilator connections

The NOxFlowTM is single

patient use. Unwrap and

carefully uncoil the lines.

Push and click-to-lock twin

sensor line to unit.

Twist dose line luer to unit.

Select a vent connector with

luer port from the NOXKITTM.

Connect the male luer of the

sample line.

12 3 4

NOxFlowTM is situated in the inspiratory limb,

before the humidier.

The sample line is up to 30cm from patient to the patient Y-piece.

NOxFlow should be approx. 1 metre back from the sample

point. Ideal range 0.7 m – 1.3 m.

For system test, high frequency and manual bagging circuit

diagrams please refer to Technical Guide.

5

Change sample line and

hydrophobic iter.

NOxBOXiOperating Instructions

®

6

www.noxboxltd.com

Dose setting & main screen features

The navigation tabs access the alarm history and user settings screens.

Alarm history: shows last 10 alarms for current treatment. Unresolved

alarms are listed at the top.

User settings: change user settings, access Manual Override

calculator, Sensor Zero and Service Engineer area.

To set or change dose press ‘edit

dose’ . The NOxBOXi will then

guide you through setting the

dose and high/low alarms. Once

conrmed the delivery and

monitoring will adjust

accordingly.

Maximum dose - 80ppm

Minimum dose - 0.1ppm

dose setting

edit dose

monitored gas

units

upper alarm

adjustment

upper alarm value

lower alarm

adjustment

lower alarm value

mute button (inactive)

monitored

value

supply

indicator

(depleated)

cylinder 2

supply concentration

supply

indicator

(gas available)

cylinder 1

time at

current dose

days:hours:mins

second timing marker

total treatment

time

days:hours:mins

NOxBOXiOperating Instructions

®

7

www.noxboxltd.com

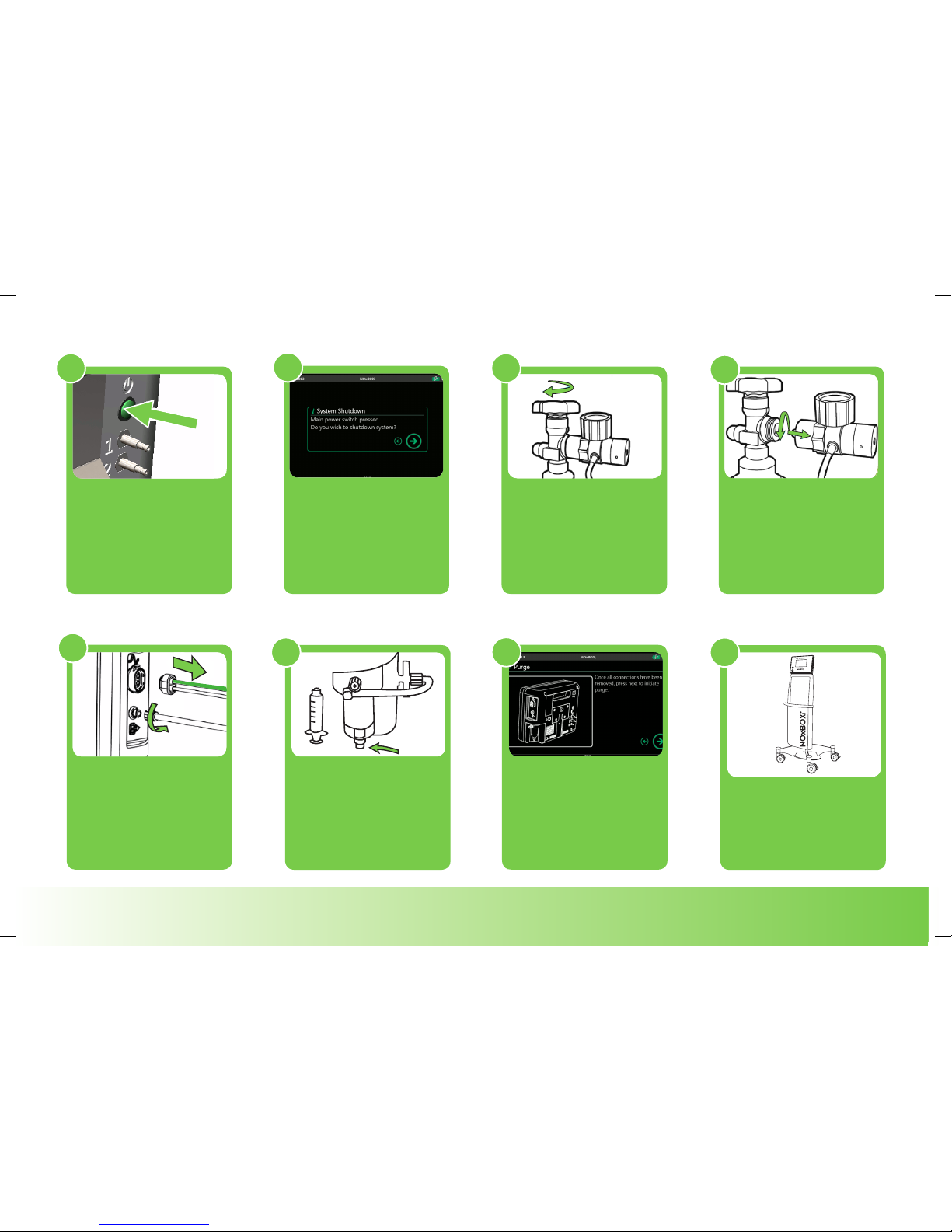

Cylinder replacement

Engage trolley brakes to

stabilise system prior to

changing cylinder.

Fully close cylinder valve.

Check regulator gauge

pressure is relieved and

remove regulator from

depleted cylinder.

Remove depleted cylinder from

trolley and replace with new

supply cylinder. Check the

concentration matches the value

displayed on-screen.

Check O rings and attach

regulator to new

cylinder.

12

5

Perform a leak test: Slowly open

the cylinder valve then close.

Observe gauge for 30 seconds,

needle should remain

stationary.

Purge pressure from hose, then

reconnect the hose to inlet port

monitor. Open valve on cylinder

fully.

7 8

34

Performaleaktest:openthe

cylindervalvethenclose.

Observegaugefor30

seconds,needleshould

remainsta>onary.

6

Detach hose from monitor and

depressurise on purge needle.

NOxBOXiOperating Instructions

®

8

www.noxboxltd.com

Conrm on-screen that

shutdown is required. Follow

on-screen instructions.

Fully close each cylinder and

depressurise the supply lines

using the purge needle.

Check regulator gauge

pressure is relieved and

remove regulator from each

cylinder and stow on system

trolley.

Remove all single patient use

devices from monitor and

dispose of according to local

regulations.

Drain water trap and dispose of

drainage syringe.

On completion of last

instruction screen, system will

purge and shutdown safely

ready for storage.

234

567

Shutdown

Remove power supply and

store on trolley for transport.

Ensure system is attached to

suitable mains supply whilst in

storage.

8

When ready to shutdown the

system, briey press the power

button on the monitor.

1

NOxBOXiOperating Instructions

®

9

www.noxboxltd.com

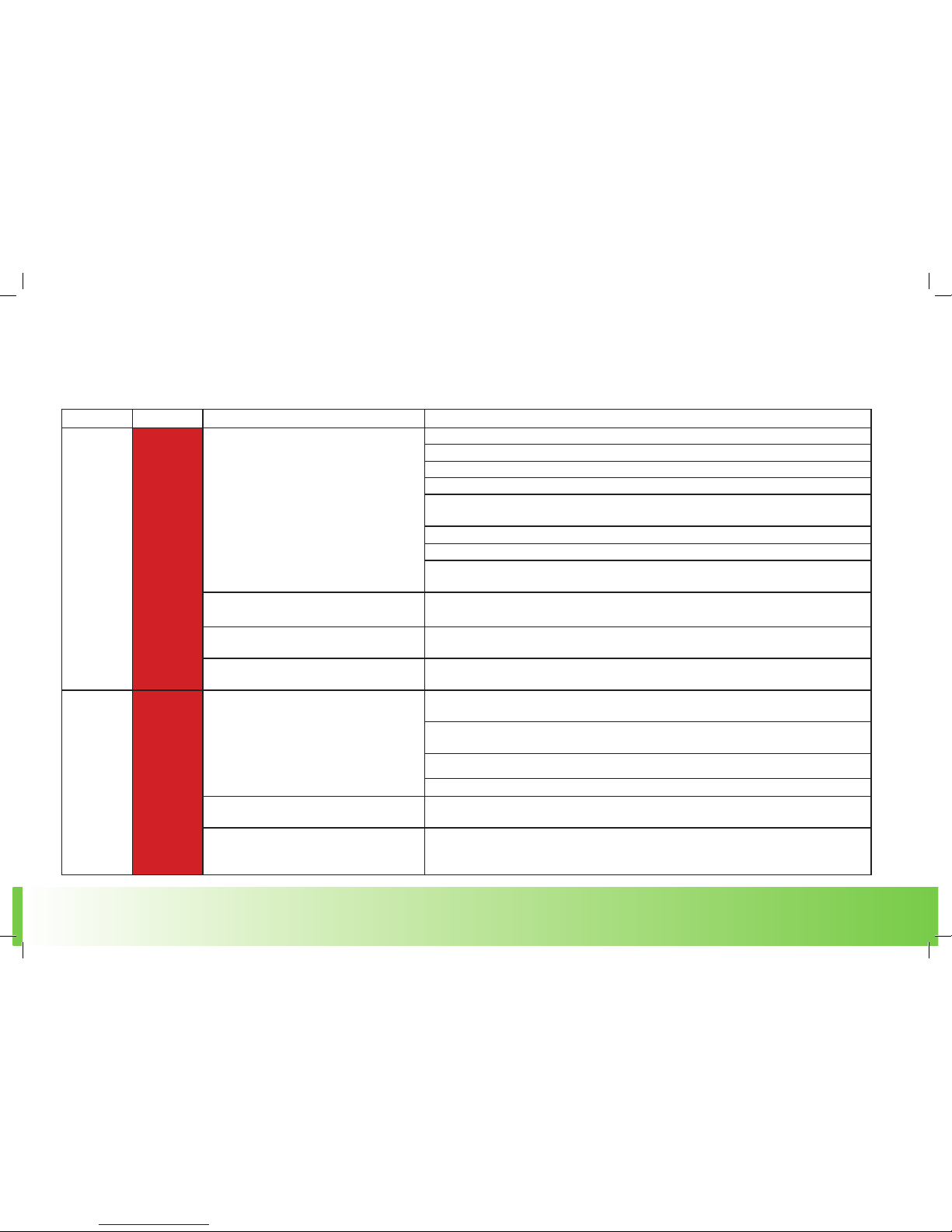

Troubleshooting Guide

ALARMS TROUBLESHOOTING

The NOxBOXiis equipped with audible and visible alarm notications; this chapter is a guide to the alarm conditions that can occur and common actions for alarm resolution. All alarms

are graded into high priority or medium priority alerts.

NOTE: In all instances of alarms sounding, the health and condition of the patient must be ensured before attempting to resolve any issue with the NOxBOXisystem.

Alarm Priorities

The system alarms are colour coded to help identify priority of detected issue. Additionally, the two alarm priorities each have an audible warning to help dierentiate them.

Priority Colour & Tone Meaning

High Red

5 tone pattern & Red L.E.D.

alarm strip.

Critical problem detected. Condition poses immediate threat to patient health or correct

functioning of the NOxBOXi monitor. Alarm condition should be diagnosed and resolved

immediately.

Medium Amber

3 tone pattern

Problem detected. Condition may impair the functioning of the NOxBOXi. If left unresolved, problem may

worsen and cause a high priority alarm condition.

NOxBOXiOperating Instructions

®

10

www.noxboxltd.com

Notications at Switch on

The below are a series of notications which may be seen at start-up (before the home screen) if an issue is detected with the NOxBOXi.

Troubleshooting Guide

Notication Priority Possible Cause Recommended

NOxBOXi System

Diagnostics

High The NOxBOXi performs self-tests at start-up and during operation

to ensure safe performance is maintained. In the event that a

critical test fails, the system will display a full-screen notice

indicating that the system can no longer be used safely.

Press the on screen reset button.

Sensor Bias Lost High The Nitric Oxide sensor requires a constant very low trickle charge

to maintain its calibration. In the event that the system is not stored

on mains power charge, after an extended period of time the

battery may completely discharge and the sensors will lose their

calibration bias.

In the event of power loss, connect the unit to mains power and allow

6 hours for the unit to charge before

calibrating the NO sensor and re-commissioning the unit.

If another system is not readily available and patient

requires therapy, engage the manual override mode, replace the

system as soon as practically possible and alert the Service Engineer.

The Nitric Oxide sensor is sensitive to extreme

temperature variation, contact with VOCs (such as

alcohol based cleaning products), strong fragrances, direct contact

with moisture or vibrations (such as during transit in a vehicle).

Follow setup steps as normal, if sensor zero fails re

attempt until the unit passes, this can take up to 30

minutes in some cases.

The NO sensor may require replacing. If another system is not readily available and patient

requires therapy, engage the manual override mode, replace the

system as soon as practically possible and alert the Service Engineer.

NOxBOXiOperating Instructions

®

11

www.noxboxltd.com

High Priority Alarms during therapy

The below are a series of alarms which may be seen during therapy (once the device has been setup) if an issue is detected with the NOxBOXi.

Troubleshooting Guide

Alarm Priority Possible Cause Recommended Action

NO Low High Monitored levels of NO gas being delivered to

the patient have dropped below the alarm

setting boundary. NOxBOXidelivery system

cannot maintain correct dose setting.

Check sample line is correctly attached to ventilator circuit and NOxBOXiwater trap inlet.

Check sample line for blockages.

Check water trap (including barrel thread) for damage and/or leaks.

Check no ventilator circuit breaks or leakages have occurred.

Check supply cylinder is connected, open; there are no leaks and the concentration matches the

system settings.

Check correct orientation of NOxFLOW.

Check NOxFLOW dose line and connection is connected and there are no blockages or leaks.

Check NOxFLOW ow detection lines and connection (including O rings) are connected and there

are no blockages or leaks.

The ventilator minute volume may be too low. Check ventilator minute volume (see NOxBOXitechnical guide for ow specications), you may

need to increase the ventilator bias ow.

The NO low alarm may be inappropriately set

by user.

Check NO low alarm value and reduce value if ventilator settings deem necessary.

The NO sensor may require replacing. If another system is not readily available and patient requires therapy, engage the manual

override mode, replace the system as soon as practically possible and alert the Service Engineer.

NO High High Monitored levels of NO gas being delivered to

the patient have risen above the alarm setting

boundary. NOxBOXi delivery system cannot

maintain the correct dose setting.

Check supply cylinder concentration matches the system settings. If possible, change the NO

supply cylinder for the correct concentration. If not, call Service Engineer to resolve.

Check no ventilator circuit break/leakage has occurred that may cause build-up of NO

concentration due to lack of ventilator ow.

Check correct orientation of NOxFLOW.

Check NOxFLOW connection (and O rings) to NOxBOXi.

The NO high alarm may be inappropriately set

by user.

Check NO high alarm value and increase value if ventilator settings deem necessary.

The NO sensor may require replacing. If another system is not readily available and patient requires therapy, engage the

manual override mode, replace the system as soon as practically possible and alert the Service

Engineer.

NOxBOXiOperating Instructions

®

12

www.noxboxltd.com

NO2High Monitored levels of NO2gas being

delivered to the patient have risen

above the alarm setting boundary.

High NO dose settings on low ventilator ows with High O2content may cause higher NO2build-up than

expected. Increase ventilator bias ow to help reduce stagnation in delivery.

Poor quality NO cylinders can

contain high levels of NO2.

Connect a second supply cylinder to the alternate inlet port. Open the cylinder and

disconnect the previous cylinder, forcing a cylinder changeover to see if this resolves the issue.

The NO2 high alarm is set to a default

value of 1.0ppm. NO2 is extremely

toxic and poses risk to patient health.

The alarm value can be increased to a maximum of 5.0ppm if required. Please see INO guidelines for more

information on maximum NO2values during INO therapy.

Incorrect placement of

NOxFLOW and sample line.

See ventilator circuit diagram for correct placement of NOxFLOW and sample line.

Whilst in standby mode NO2can build

up in supply lines.

Purge supply lines (see cylinder change procedure).

Stagnant gas in manual bag circuit

causing NO2.

Purge manual bag circuit before connecting to

patient (see manual bagging procedure).

The NO2sensor may require

replacing.

If another system is not readily available and patient requires therapy, engage the manual override mode,

replace the system as soon as practically

possible and alert the Service Engineer.

O2Low High Monitored levels of O2 gas being

delivered to the patient have fallen

below the alarm setting boundary.

Check sample line for blockages.

Check water trap (including barrel thread) for

damage and/or leaks.

Check sample line is correctly attached to ventilator circuit and NOxBOXi water trap inlet.

Check no ventilator circuit breaks or leakages have occurred.

The NO gas is balanced in N2, this is

an asphyxiant gas. At high NO dose

levels for low concentration cylinders

(e.g. 200 ppm) the level of gas

delivered into the ventilator stream

can reduce the % v/v of O2being

delivered to the patient.

Check O2concentration setting at ventilator.

Adjust O2 alarm value if deemed necessary.

The O2sensor may require

replacing.

If another system is not readily available and patient requires therapy, engage the manual override mode,

replace the system as soon as practically possible and alert the Service Engineer.

Troubleshooting Guide

NOxBOXiOperating Instructions

®

13

www.noxboxltd.com

NO2High Monitored levels of NO2gas being

delivered to the patient have risen

above the alarm setting boundary.

High NO dose settings on low ventilator ows with High O2content may cause higher NO2build-up than

expected. Increase ventilator bias ow to help reduce stagnation in delivery.

Poor quality NO cylinders can

contain high levels of NO2.

Connect a second supply cylinder to the alternate inlet port. Open the cylinder and

disconnect the previous cylinder, forcing a cylinder changeover to see if this resolves the issue.

The NO2 high alarm is set to a default

value of 1.0ppm. NO2 is extremely

toxic and poses risk to patient health.

The alarm value can be increased to a maximum of 5.0ppm if required. Please see INO guidelines for more

information on maximum NO2values during INO therapy.

Incorrect placement of

NOxFLOW and sample line.

See ventilator circuit diagram for correct placement of NOxFLOW and sample line.

Whilst in standby mode NO2can build

up in supply lines.

Purge supply lines (see cylinder change procedure).

Stagnant gas in manual bag circuit

causing NO2.

Purge manual bag circuit before connecting to

patient (see manual bagging procedure).

The NO2sensor may require

replacing.

If another system is not readily available and patient requires therapy, engage the manual override mode,

replace the system as soon as practically

possible and alert the Service Engineer.

O2Low High Monitored levels of O2 gas being

delivered to the patient have fallen

below the alarm setting boundary.

Check sample line for blockages.

Check water trap (including barrel thread) for

damage and/or leaks.

Check sample line is correctly attached to ventilator circuit and NOxBOXi water trap inlet.

Check no ventilator circuit breaks or leakages have occurred.

The NO gas is balanced in N2, this is

an asphyxiant gas. At high NO dose

levels for low concentration cylinders

(e.g. 200 ppm) the level of gas

delivered into the ventilator stream

can reduce the % v/v of O2being

delivered to the patient.

Check O2concentration setting at ventilator.

Adjust O2 alarm value if deemed necessary.

The O2sensor may require

replacing.

If another system is not readily available and patient requires therapy, engage the manual override mode,

replace the system as soon as practically possible and alert the Service Engineer.

Water Trap

Full

High Water trap is lled with condensate from sample line.

If the water trap is allowed to overow, the sample

path will block and water ingress to the NOxBOXi

system could damage the internal mechanisms and

gas sensors. Delivery accuracy is compromised and

patient safety could be put at risk.

Use disposable male-luer lock syringe contained in NOXKIT to empty uid from

water trap via the self-sealing drain tap located at the bottom of the water trap.

Dispose of entire syringe and contents according to local directives (e.g. sharps waste).

The water trap uses a small oat to activate the alarm, if no

moisture is present gently tap the barrel to see if the alarm oat is

in the o position.

If issues persist, remove the barrel and check position of alarm oat.

Removing the water trap barrel will dilute NO sample causing inaccurate dose and readings.

Take care not to damage/cross thread the water trap thread when

replacing the barrel.

Sample Line

block

High Sample line to monitor has become blocked, pinched

or occluded. Sample monitoring is

aected which may compromise deliveryaccuracy

and patient safety.

Check sample line for any pinch/crush points from external bodies, or blockages that may have

occurred.

Check water trap does not require emptying.

Change sample line and hydrophobic lter.

If another system is not readily available and patient requires therapy, engage the manual

override mode, replace the system as soon as practically possible and alert the Service Engineer.

Battery

Critical

High NOxBOXiis running from internal battery and battery

charge level has been detected as critical. System

power could fail within the next 10

minutes. Power failure will stop automatic

intelligent delivery of NO.

Reconnect the NOxBOXisystem to the mains using the NOxBOXipower supply. This will ensure

continued powered operation of the NOxBOXi and will start to recharge the internal battery.

Check green (mains power) L.E.D on mains power plug is lit indicating mains supply OK. If not,

try a dierent mains power socket/supply.

Disconnect power supply and reconnect, check blue (charging) L.E.D is lit indicating mains

supply OK. If not, try a dierent mains power/supply.

If possible replace NOxBOXipower supply and alert service engineer.

Troubleshooting Guide

NOxBOXiOperating Instructions

®

14

www.noxboxltd.com

Troubleshooting Guide

In the event that no mains power can be restored to the device, be prepared to engage the

manual override mode.

Cylinder

Supply

Critical

High NOxBOXidetects that available NO gas

supply is running low, and no alternate

cylinder supply is detected. Without action to

replenish the NO gas supply treatment

delivery will cease.

Install a new gas cylinder supply and connect to the alternate gas inlet port at the rear of

NOxBOXi.

If a new gas cylinder is already installed, ensure the cylinder valve is fully open and

connected to inlet port at rear to allow the device to use the supply for delivery.

Check the supply cylinder regulator gauges indicate adequate cylinder pressure (>20bar). If

regulator gauge indicates adequate pressure, check for leaks. If issues persist, replace regulator and

alert service engineer.

Vent Flow

Idle

High The NOxFLOW has not detected any vent ow

activity for an extended period of time (typically

over 30 seconds) during delivery.

Check correct orientation of NOxFLOW; the green arrow printed on the NOxFLOW should be

pointing towards the patient in the direction of the ventilator ow.

Check NOxFLOW ow detection lines and connection (including O rings) are connected and there

are no blockages or leaks.

Check there is not a serious leak or break in the ventilator circuit. Attend to the ventilator circuit

requirements.

Check the ventilator is connected and supplying sucient ow.

Critical

Delivery

Fault

High The NOxBOXihas detected a critical fault within

the intelligent delivery system, and can no

longer guarantee safe delivery function.

If another system is not readily available and patient requires therapy, engage the

manual override mode, replace the system as soon as practically possible and alert the

Service Engineer.

Occlusion on NO outlet. Check for occlusions on the NO outlet, delivery line or NOxFLOW. Once resolved, reset the dose to

resume delivery.

Touch screen

won’t

respond.

High The NOxBOXihas detected a critical fault within

the intelligent delivery system, and can no

longer guarantee safe delivery function. NO

delivery to the patient may have stopped.

If another system is not readily available and patient requires therapy, engage the

manual override mode, replace the system as soon as practically possible and alert the

Service Engineer.

NOxBOXiOperating Instructions

®

15

www.noxboxltd.com

Troubleshooting Guide

Medium Priority Alarms during therapy

Alarm Priority Possible Cause Recommended Action

Zero

Calibration

Medium Every 24 hours during use the NOxBOXi prompts

the user to perform a sensor zero. This operation

ensures the most accurate system performance by

checking the gas sensor

reading performance.

NOTE: This test takes up to 2 minutes to perform.

During this time the monitored patient gases will

be oine. The NOxBOXicontinues to deliver NO

during this time.

No special connections are required; the zero calibration is fully automatic.

Press the tick to start the zero calibration.

The zero calibration can be delayed if the system is not currently in a stable dose delivery state:

e.g. If the patient dose has recently been changed and the system is still stabilising to the new

dose level, dismiss this alarm message and perform the zero when the notice next appears.

Zero

Calibration

Fail

Medium One or all of the sensors have failed the zero (low)

calibration.

Ambient conditions may be aecting the zero

sample.

Check ambient NOxAIR monitor for high levels of NO. If high levels are detected, check the

regulator(s) and supply line(s) for leaks.

A sensor may have become unstable or residual

gas may be present in the system.

Repeat zero calibration.

Check the zero port (rear) has not been blocked.

If another system is not readily available and patient requires therapy, engage the manual

override mode, replace the system as soon as practically possible and alert the Service Engineer.

Cylinder Low Medium This will appear when an alternate viable gas

supply is detected, but the current feed cylinder is

nearly depleted.

Replace the cylinder with a fresh supply to resolve this alarm.

Alternatively, once the cylinder is empty, close the cylinder valve fully, remove the feed hose from

the rear of the system and release the pressure using the purge needle on the monitor. Please

note, once the second cylinder begins to deplete, if this rst cylinder has not been

replaced in the interim period, the‘cylinder supply critical’ alarm will be triggered.

NOxBOXiOperating Instructions

®

16

www.noxboxltd.com

Troubleshooting Guide

High

Calibration

Overdue

Medium To keep the NOxBOXifunctioning accurately, it is

important that the system sensors be fully calibrated by

a suitably qualied Service Engineer once a month.

The system records the last date of each successful

calibration in the service engineer section.

This action may be performed whilst the system is in use via the service

engineer area. However Bedfont strongly recommend that the sensor high

calibrations are not performed during therapy to minimise risk to the patient.

To resolve, the system sensors must be calibrated by the appointed Systems Engineer using

calibration gases.

Manual

Override

Medium Manual Override mode is engaged.

The system alarms to alert the user that the system is not

delivering in intelligent mode. Changes to the ventilator

setting or patient demand cannot be automatically

corrected on the system. A specic dose setting cannot

be dialled in and achieved.

The patient must be closely monitored and ensure the

gas alarms are correctly set to alert for any

abnormal gas delivery behaviour.

This alarm will resolve when the system is returned to normal Intelligent

Delivery Mode.

NOxBOXiOperating Instructions

®

17

www.noxboxltd.com

General Troubleshooting

Issue Possible Cause Recommended Action

NOxBOXiturns on and o

immediately. NOxBOXi

attempts to start up but shuts

down.

NOxBOXiwon’t turn on at all.

Low battery power. Connect NOxBOXito mains power and turn on NOxBOXi.

Check mains power is connected and battery is charging (see battery critical).

An internal fault has occurred; the system shuts

down to protect integral components.

If another system is not readily available and patient requires therapy, engage the

manual override mode, replace the system as soon as practically possible and alert the

Service Engineer.

Zero Calibration Fail One or all of the sensors have failed the zero (low)

calibration.

Ambient conditions may be aecting the zero

sample.

Check ambient NOxAIR monitor for high levels of NO. If high levels are detected, check the

regulator(s) and supply line(s) for leaks.

One or all of the sensors may have become unstable

or residual gas may be present in the system.

Repeat zero calibration.

Check the zero port (rear) has not been blocked.

If another system is not readily available and patient requires therapy, engage the

manual override mode, replace the system as soon as practically possible and alert the

Service Engineer.

System Test Fail The NOxBOXihas failed the safety test and

cannot accurately deliver and monitor Nitric Oxide

inintelligent mode.

Check the Oxygen source is owing.

Check the NOxFLOW is connected to the Oxygen source and the NOxBOXi-TEST kit.

Check the correct orientation of NOxFLOW.

Check the NOxFLOW is connected to the NOxBOXi.

Check NOxFLOW ow detection lines and connector O rings for damage.

Check sample line is connected to the water trap and the NOxBOXi-TEST kit.

Check water trap (including barrel thread) for damage.

Repeat the system test.

If second test fails, replace the NOxFLOW and sample line.

One or all of the sensors may have become unstable. If another system is not readily available and patient requires therapy, engage the

manual override mode, replace the system as soon as practically possible and alert the

Service Engineer.

Fluctuations/ Oscillations in

excess of 3ppm.

May be due to noxow. Ensure O-ring and NOxFLOW are present and connected.

Mass ow sensor due for service. Contact Service Engineer.

HFO frequency. Adjust the frequency slightly based upon your clinical judgement.

NOxBOXiOperating Instructions

®

18

www.noxboxltd.com

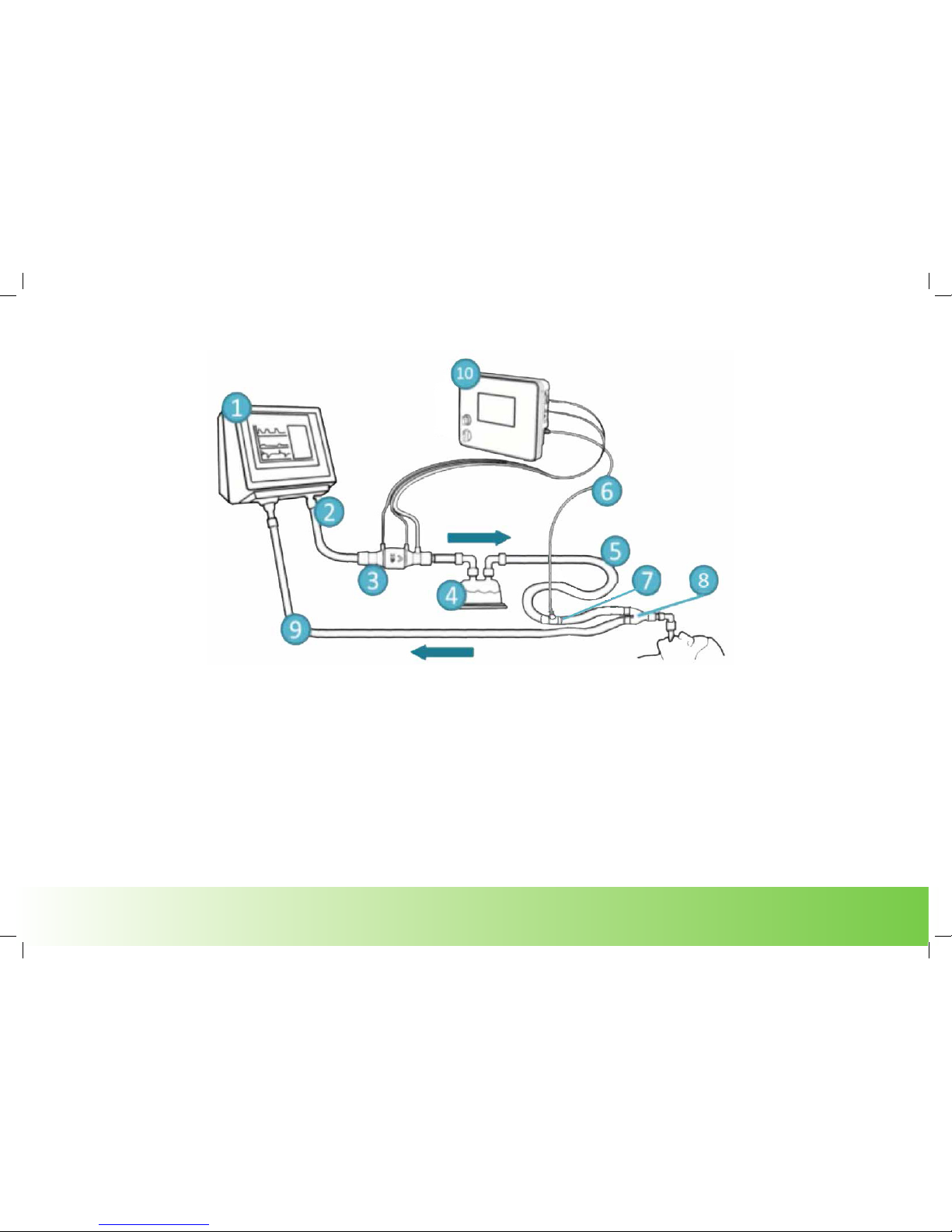

Conventional ventilator circuit

NOTE: To improve accuracy it is recommended to have up to 30cm between the patient Y-Piece (8) and the sample line (7).

1. Ventilator

2. Ventilator Inspiratory Port

3. NOxFLOWTM (use 22F or 15M to vent tube adaptors)

4. Humidier

5. 0.7m-1.3m Corrugated Tubing (15mm or 22mm)

6. NOxBOXi Sample Line

7. 10M - 10F, 12M - 12F, 15M - 15M luer port or 22M-22F luer port connector

8. Patient Y-piece

9. Expiratory limb

10. NOxBOXi

NOxBOXiOperating Instructions

®

19

www.noxboxltd.com

Manual override

NOTE: All dose information for the Manual Override are

approximations. Monitoring must be used to ensure the

patient is receiving the correct dose.

B

If Manual Override is required:

First check suitable ow rate is set.

Then engage mode selection valve to the

position seen on right hand side image.

2

A

A

B

B

Using on-screen

calculator access the

manual override

calculator from Settings.

Adjust vent ow to best match

patient settings. Table displays

approx. dose per valve setting.

Use the look-up tables in this

guide. To set ow rate, nd the

table matching NO

supply concentration.

Find the vent ow setting to

best match patient settings.

The column lists the approx.

dose per valve setting.

A

AB

To set ow rates

1

OR

600

B

NOxBOXiOperating Instructions

®

20

www.noxboxltd.com

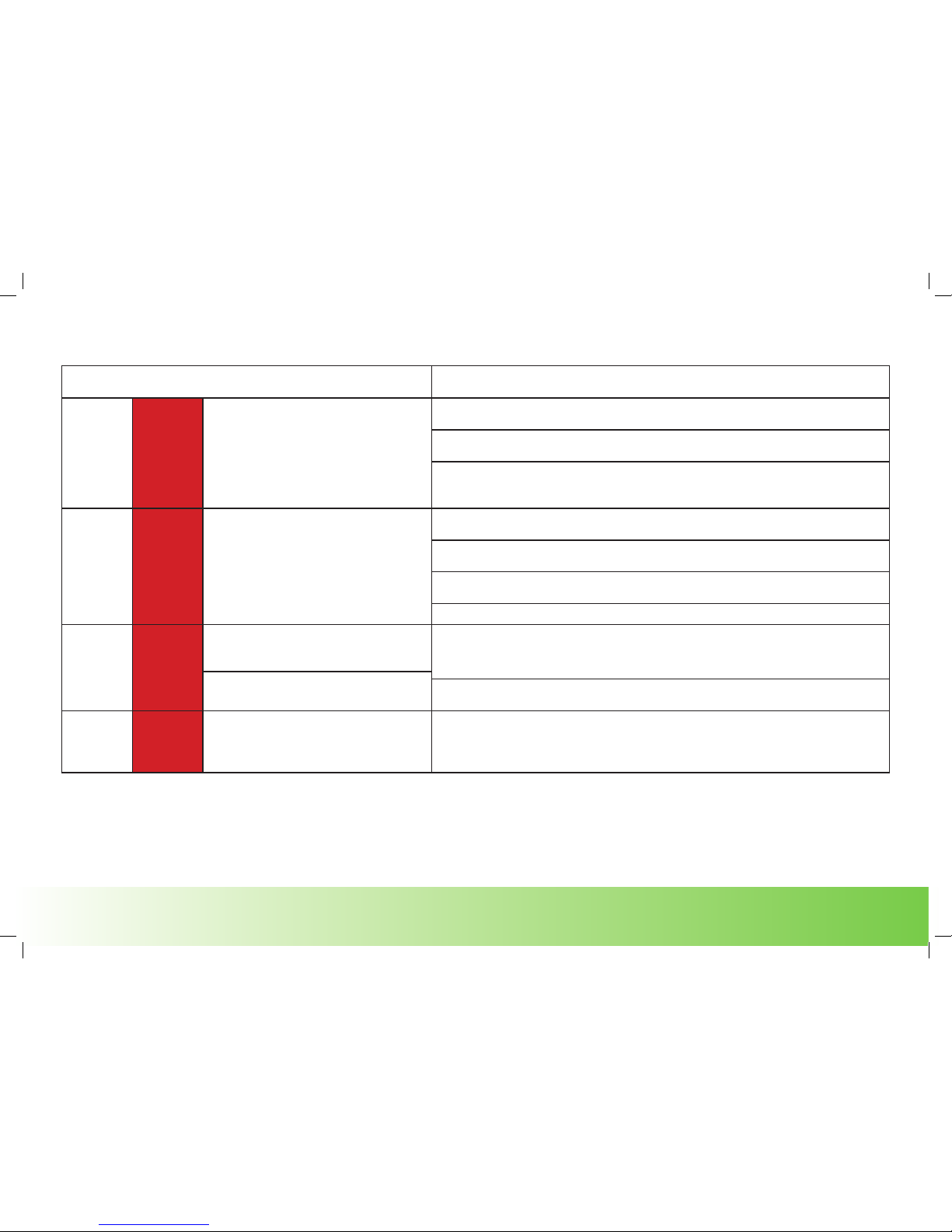

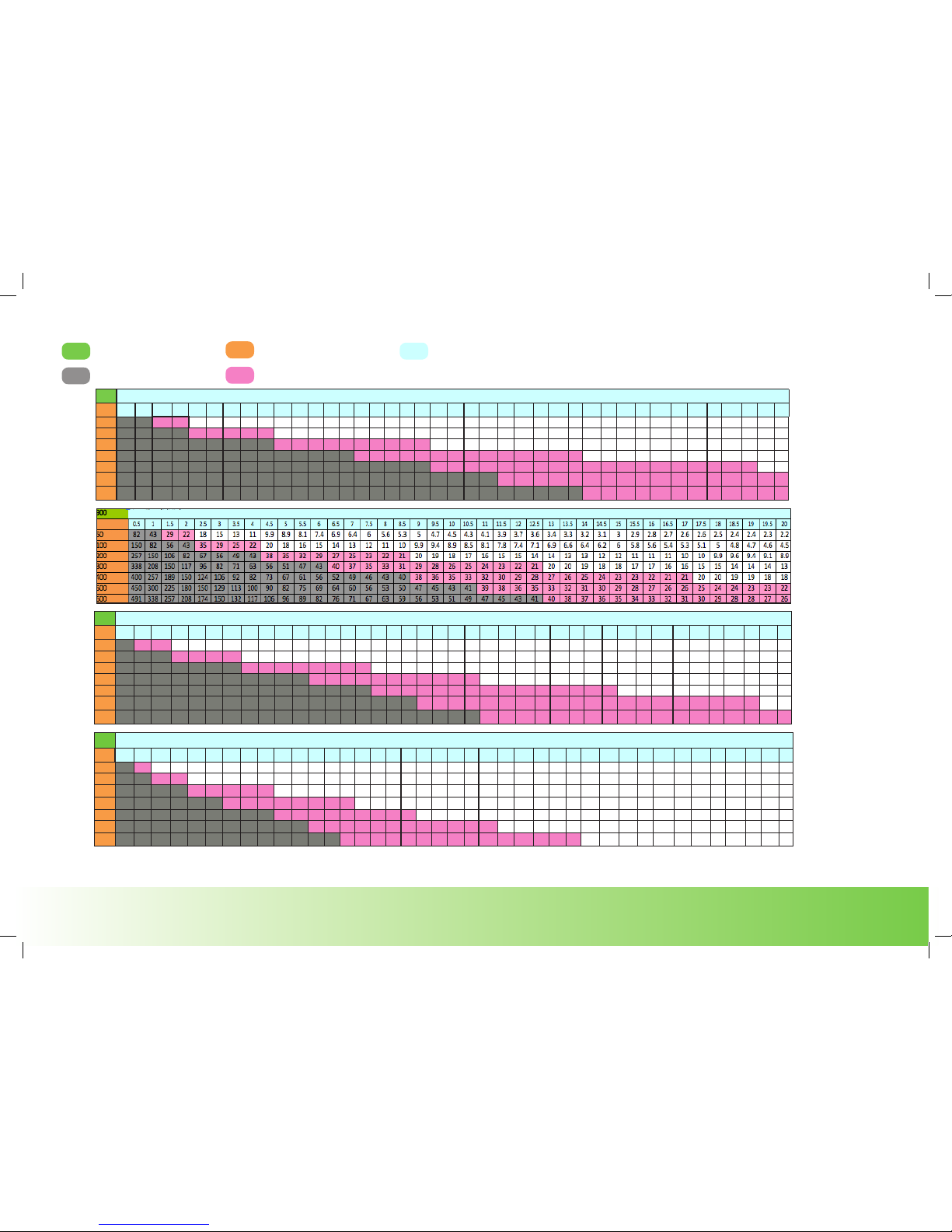

All dose information shown in these tables is for guidance only. The patient monitored gas levels should be used for actualy dose delivery information. All nitric oxide (NO) doses shown in parts per million

(ppm) when introduced to continuous ow rates indicated. Doses of NO above 40 ppm are not recommended. Doses above 20ppm are considered clinically high.

Flow valve setting Minute ow volume

Clinder Concentration (ppm)

800

0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 7 7.5 8 8.5 9 9.5 10 10.5 11 11.5 12 12.5 13 13.5 14 14.5 15 15.5 16 16.5 17 17.5 18 18.5 19 19.5 20

50 73 38 26 20 16 13 11 9.9 8.8 7.9 7.2 6.6 6.1 5.7 5.3 5 4.7 4.4 4.2 4 3.8 3.6 3.5 3.3 3.2 3.1 3 2.8 2.7 2.7 2.6 2.5 2.4 2.3 2.3 2.2 2.2 2.1 2 2

100 133 73 50 38 31 26 22 20 17 16 14 13 12 11 11 9.9 9.3 8.8 8.3 7.9 7.5 7.2 6.9 6.6 6.3 6.1 5.9 5.7 5.5 5.3 5.1 5 4.8 4.7 4.5 4.4 4.3 4.2 4.1 4

200 229 133 94 73 59 50 43 38 34 31 28 26 24 22 21 20 18 17 16 16 15 14 14 13 13 12 12 11 11 11 10 9.9 9.6 9.3 9 8.8 8.6 8.3 8.1 7.9

300 300 185 133 104 86 73 63 56 50 45 41 38 35 33 31 29 27 26 24 23 22 21 20 20 19 18 17 17 16 16 15 15 14 14 13 13 13 12 12 12

400 356 229 168 133 110 94 82 73 65 59 54 50 46 43 41 38 36 34 32 31 29 28 27 26 25 24 23 22 21 21 20 20 19 18 18 17 17 16 16 16

500 400 267 200 160 133 114 100 89 80 73 67 62 57 53 50 47 44 42 40 38 36 35 33 32 31 30 29 28 27 26 25 24 24 23 22 22 21 21 20 20

600 436 300 229 185 155 133 117 104 94 86 79 73 68 63 59 56 53 50 48 45 43 41 40 38 37 35 34 33 32 31 30 29 28 27 27 26 25 24 24 23

1000

0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 7 7.5 8 8.5 9 9.5 10 10.5 11 11.5 12 12.5 13 13.5 14 14.5 15 15.5 16 16.5 17 17.5 18 18.5 19 19.5 20

50 91 48 32 24 20 16 14 12 11 9.9 9 8.3 7.6 7.1 6.6 6.2 5.8 5.5 5.2 5 4.7 4.5 4.3 4.1 4 3.8 3.7 3.6 3.4 3.3 3.2 3.1 3 2.9 2.8 2.8 2.7 2.6 2.6 2.5

100 167 91 63 48 38 32 28 24 22 20 18 16 15 14 13 12 12 11 10 9.9 9.4 9 8.6 8.3 7.9 7.6 7.4 7.1 6.8 6.6 6.4 6.2 26 5.8 5.7 5.5 5.4 5.2 5.1 5

200 286 167 118 91 74 63 54 48 43 38 35 32 30 28 26 24 23 22 21 20 19 18 17 16 16 15 15 14 14 13 13 12 12 12 11 11 11 10 10 9.9

300 375 231 167 130 107 91 79 70 63 57 52 48 44 41 38 36 34 32 31 29 28 27 25 24 23 23 22 21 20 20 19 18 18 17 17 16 16 16 15 15

400 444 286 211 167 138 11 8 103 91 82 74 68 63 58 54 51 48 45 43 40 38 37 35 34 32 31 30 29 28 27 26 25 24 24 23 22 22 21 21 20 20

500 500 333 250 200 167 143 125 111 100 91 83 77 71 67 63 59 56 53 50 48 45 43 42 40 38 37 36 34 33 32 31 30 29 29 28 27 26 26 25 24

600 545 375 286 231 194 167 146 130 118 107 98 91 85 79 74 70 66 63 59 57 54 52 50 48 46 44 43 41 40 38 37 36 35 34 33 32 31 31 30 29

WARNING: Dose >40 ppm Dose over 20ppm

Minute Volume (L/Min)

Minute Volume (L/Min)

Dial

Dial

Minute Volume (L/Min)

Dial

500

0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 7 7.5 8 8.5 9 9.5 10 10.5 11 11.5 12 12.5 13 13.5 14 14.5 15 15.5 16 16.5 17 17.5 18 18.5 19 19.5 20

50 45 24 16 12 9.8 8.2 7 6.2 5.5 5 4.5 4.1 3.8 3.5 3.3 3.1 2.9 2.8 2.6 2.5 2.4 2.3 2.2 2.1 2 1.9 1.8 1.8 1.7 1.7 1.6 1.6 1.5 1.5 1.4 1.4 1.3 1.3 1.3 1.2

100 83 45 31 24 19 16 14 12 11 9.8 8.9 8.2 7.6 7 6.6 6.2 5.8 5.5 5.2 5 4.7 4.5 4.3 4.1 4 3.8 3.7 3.5 3.4 3.3 3.2 3.1 3 2.9 2.8 2.8 2.7 2.6 2.6 2.5

200 143 83 59 45 37 31 27 24 21 19 18 16 15 14 13 12 11 11 10 9.8 9.3 8.9 8.5 8.2 7.9 7.6 7.3 7 6.8 6.6 6.4 6.2 6 5.8 5.6 5.5 5.3 5.2 5.1 5

300 188 115 83 65 54 45 39 35 31 28 26 24 22 21 19 18 17 16 15 15 14 13 13 12 12 11 11 10 10 9.8 9.5 9.2 8.9 8.7 8.4 8.2 8 7.8 7.6 7.4

400 222 143 105 83 69 59 51 45 41 37 34 31 29 27 25 24 22 21 20 19 18 18 17 16 16 15 14 14 13 13 13 12 12 11 11 11 11 10 10 9.8

500 250 167 125 100 83 71 63 56 50 45 42 38 36 33 31 29 28 26 25 24 23 22 21 20 19 19 18 17 17 16 16 15 15 14 14 14 13 13 13 12

600 273 188 143 11 5 97 83 73 65 59 54 49 45 42 39 37 35 33 31 30 28 27 26 25 24 23 22 21 21 20 19 19 18 18 17 17 16 16 15 15 15

Dial

Minute Volume (L/Min)

Dose look-up table

1000ppm, 900ppm, 800ppm, 500ppm

Other manuals for NOxBOXi

1

Table of contents

Other NoxBox Medical Equipment manuals

Popular Medical Equipment manuals by other brands

TheraTogs

TheraTogs TogRite quick start guide

Kyoto Kagaku

Kyoto Kagaku MW8 instruction manual

Winncare

Winncare AERYS-120 user manual

Graham Field

Graham Field Lumex LCMP100 Operation instructions

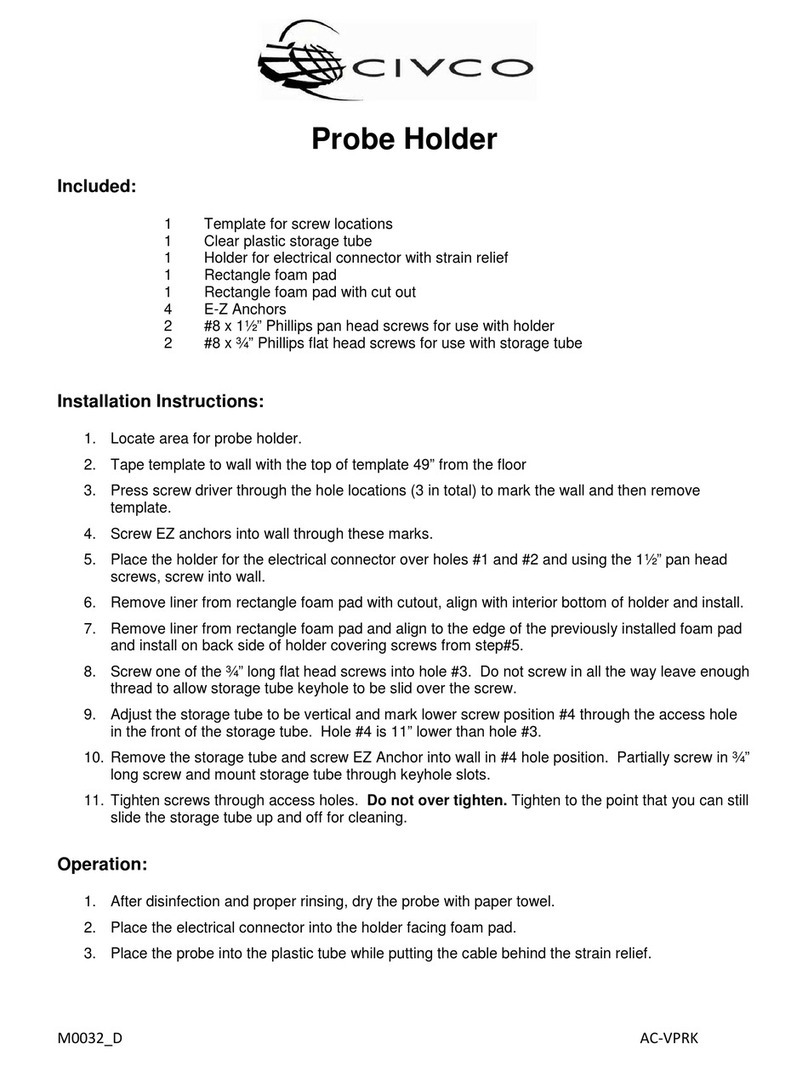

Civco

Civco 610-2052 quick guide

medi

medi circaid juxtalite ankle foot wrap inelastic compression... Instructions for use