8National Rejectors, Inc. GmbH, Buxtehude

GENERALINFORMATION

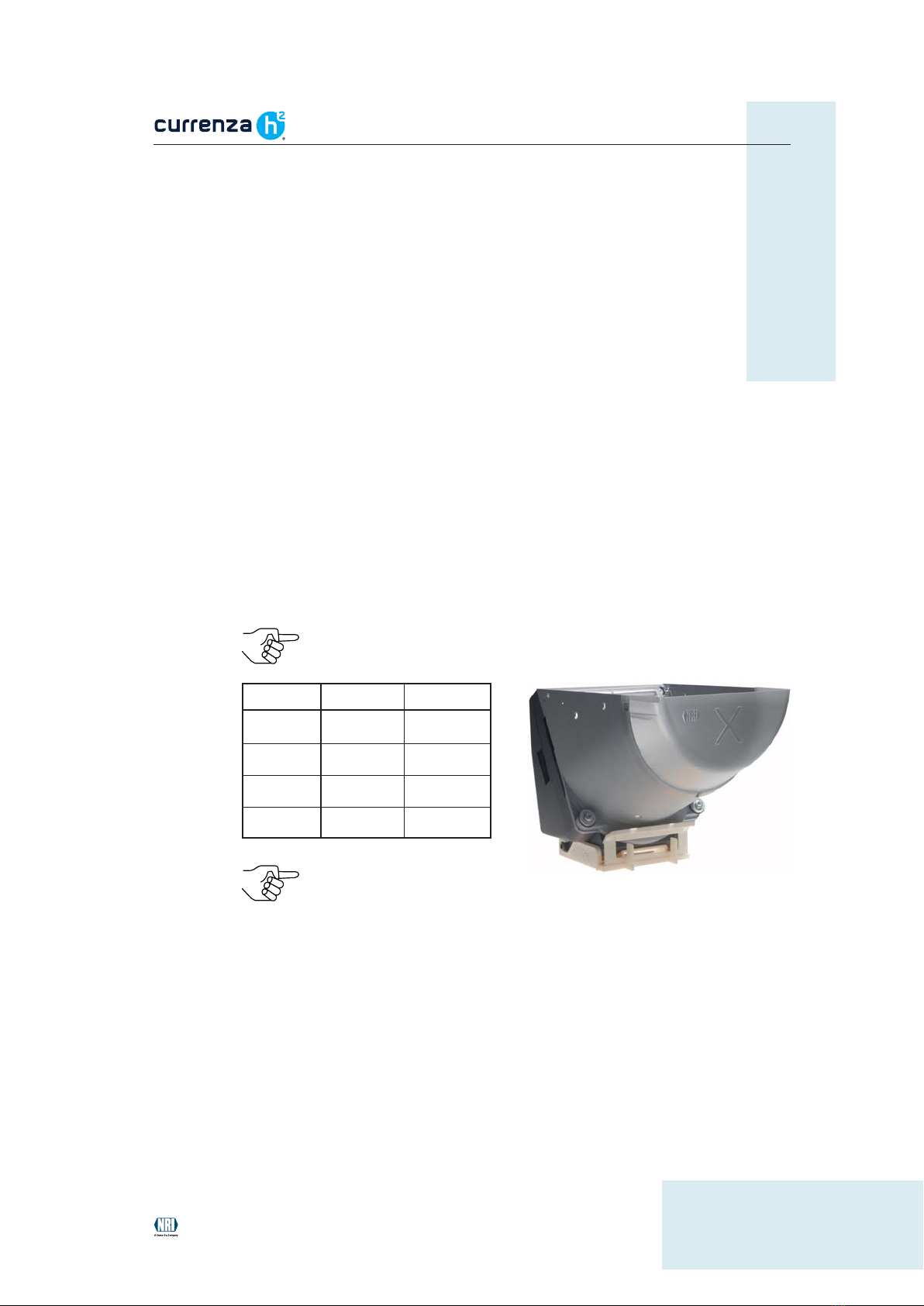

General information about the hopper currenza h2

The electromechanic hopper currenza h2is a coin payout system for

machines.Dependingonthemodelandthecointypeitcancollect2,000and

more coins, in order to be able to pay out these coins as change on

command of the machine control system. Due to its high capacity the

hopper is used in machines, that have to pay out certain coins as change

frequently, such as money changers, vending and amusement machines.

Thehopper modelsh2L andh2X areprojected andcannot be

deliveredyet.

The hopper is fitted with a machine interface, that can be configured for

parallelorserialccTalk operation accordingtorequirements.In thecaseof

the parallel interface the hopper communicates with the machine control

system using signal lines, whereas the ccTalk interface allows the hopper

to use the serial ccTalk data transfer protocol to communicate with the

control system as slave. The interface is configured according to customer

requirements on delivery.

The reliable and low-maintenance payout mechanism in the form of a

rotating disc driven by a motor is designed extra ruggedly, so that it

withstands innumerous coin payouts permanently.

Ifthehopperistobefilledautomatically,itcaninteractwithacoinvalidation

system without any problems (e.g. NRI coin validators G-13.mft, G-40 or

NRI coin changers c2, E-66/A-66, G-46).

The currenza h2features

• Models in various sizes for a coin capacity as high as possible

depending on the machine dimensions

• Space-saving dual hopper installation thanks to coin passage

• switchable machine interface for parallel or serial ccTalk operation

• Suitable for paying out a lot of different coin types

• Payout speed of up to 7.5 coins per second

• Operating safety due to coin payout sensors, automatic error

detection and anti-jam function

• Optional empty and full recognition