NSK Bruel & Kjaer Vibro VCM-3 User manual

Keep it accessible for future reference

UNRESTRICTED DOCUMENT

Instruction

VIBRO Condition Monitoring 3

VCM-3

On-site Commissioning

Copyright © 2022 Brüel & Kjær Vibro GmbH

All rights to this technical documentation remain reserved.

Any corporeal or incorporeal reproduction or dissemination of this technical documentation or making this

document available to the public without prior written approval from Brüel & Kjær Vibro GmbH shall be

prohibited. This also applies to parts of this technical documentation.

Instruction VCM-3 On-Site Commissioning, C107759.002 / V03, en, date of issue: 29.03.2022

Brüel & Kjær Vibro GmbH

Leydheckerstrasse. 10

64293 Darmstadt

Germany

Phone: +49 6151 428 0

Fax: +49 6151 428 1000

Brüel & Kjær Vibro A/S

Lyngby Hovedgade 94, 5 sal

2800 Lyngby

Denmark

Phone: +45 69 89 03 00

Fax: +45 69 89 03 01

BK Vibro America Inc

1100 Mark Circle

Gardnerville NV 89410

USA

Phone: +1 (775) 552 3110

Homepage

www.bkvibro.com

Trademarks and Copyrights

All trademarks, service marks, and/or registered trademarks used in this document belong to BK Vibro America

Inc., except as noted below:

Microsoft®, Microsoft® software, Windows®, Windows® operating system are either registered trademarks or

trademarks of Microsoft Corporation in the United States and/or other countries.

Trademarks used herein are the property of their respective owners.

© Brüel & Kjær Vibro ● C107759.002 / V03 Page 3 of 22

Technical alterations reserved!

Brüel & Kjær Vibro │Instruction VCM-3 On-Site Commissioning

Table of Contents

EN

UNRESTRICTED DOCUMENT

Table of Contents

1Introduction..............................................................................................................4

1.1 Scope .....................................................................................................................................................4

1.2 Firmware version ..................................................................................................................................5

1.3 Document Conventions .......................................................................................................................5

2On-site Commissioning of VCM-3..........................................................................6

2.1 Prerequisites .........................................................................................................................................6

3Initial Power Up test –Visual check.......................................................................7

3.1 Investigation of deviations in LED colors after initial power up......................................................9

3.1.1 Sensor problems on connected sensors (signal inputs).........................................................................................9

3.1.2 CCS (constant current supply) sensors..................................................................................................................9

3.1.3 Non-CCS sensors ................................................................................................................................................10

3.1.4 VCM-3 hardware (device) problems.....................................................................................................................10

4VCM-3 Homepage Commissioning Procedure....................................................12

4.1 Log into the VCM-3 Homepage..........................................................................................................12

4.2 Check the VCM-3 firmware version and update firmware..............................................................13

4.3 Check the Operational Status............................................................................................................14

4.4 Check bias voltages of sensors........................................................................................................15

4.5 Make tap test of the accelerometers.................................................................................................16

4.6 Configuration ......................................................................................................................................17

4.7 Document the completed commissioning process ........................................................................18

4.8 Completing on-site commissioning –visible check .......................................................................19

5Appendix 1: Update VCM-3 firmware...................................................................20

6Appendix 2: Power Up/Down and Reboot ...........................................................21

Page 4 of 22 © Brüel & Kjær Vibro ●C107759.002 / V03

Technical alterations reserved!

EN

UNRESTRICTED DOCUMENT

1 Introduction

1.1 Scope

The purpose of the On-site commissioning procedure is to bring the VCM-3 in an operational state.

•To check that the VCM-3 boots up correctly.

•To verify that all channels which shall be used for monitoring the machine, are wired correctly

and responds correctly to a tap test.

•To finalize the commissioning procedures, configure the network and define the machine

name.

Before starting these procedures, it is assumed that the physical system installation has been

checked. See C107758.002 EN Hardware Installation Instruction.

The test described in the following sections is based on the factory test template which is initially

loaded as part of the VCM-3 firmware. The factory monitoring (test) template is running by default in

the VCM-3 when it is started up for the on-site commissioning procedure. When the on-site

commissioning procedure has been completed the monitoring template, which will provide the VCM-

3 with the correct personality for the particular machine type can be uploaded to the VCM-3

Homepage and activated on the device.

NOTE!

The procedures described in this instruction assume that the VCM-3 has not been

commissioned before (factory settings apply).

Overview of factory monitoring (test) template

Channel

1-10 Configured for CCS accelerometers (Constant Current Source)

11-12 Configured for MEMS based Tower sensors

13-16 Configured for Speed sensors

17-24 Configured for 4-20mA sensors

Descriptor list

For each AC/DC channel:

•Offset voltage

•50Hz level

•60Hz level

For each Speed/DC channel

•Voltage reading

•50Hz level

•60Hz level

For each 4-20mA channel

•Current reading

NOTE!

If other sensor configurations are required for an installation test, please contact

Brüel & Kjær Vibro Technical support support@bkvibro.com.

© Brüel & Kjær Vibro ● C107759.002 / V03 Page 5 of 22

Technical alterations reserved!

Brüel & Kjær Vibro │Instruction VCM-3 On-Site Commissioning

Introduction

EN

UNRESTRICTED DOCUMENT

1.2 Firmware version

Different firmware versions behave differently and looks (slightly) different. This version of the

document describes the look and feel of firmware version 1.22. Older versions as used in the

drawings will in general look the same but can have vital differences in what a LED color means.

Always use a manual that match the Firmware version you have.

1.3 Document Conventions

Feature

Comments

Menu items, buttons, tabs,

UI features, keyboard

instruction

Indicated by bold type face. Examples: Click Remove. Press

Ctrl+Shift or Press F12.

Path denotations

Example: File > Template > Load template

Important Note!

Important Note indicates information which is potentially serious to

either personnel or to the unit.

Note!

Note text is for special attention. The information is very important for

the correct operation of the system.

Tables with grey header

The content of these tables is only for information.

Page 6 of 22 © Brüel & Kjær Vibro ●C107759.002 / V03

Technical alterations reserved!

EN

UNRESTRICTED DOCUMENT

2 On-site Commissioning of VCM-3

2.1 Prerequisites

To complete the on-site commissioning procedure, the following must be available:

A service laptop with:

1. A Microsoft Edge browser or Mozilla Firefox browser. Due to the installed security certificates on

the VCM-3 the Google Chrome browser has difficulties in showing the VCM-3 Homepage.

When you address the VCM-3 Homepage in either Microsoft Edge or Firefox some security

alerts are shown. These shall be ignored.

2. The latest VCM-3 firmware version. This is optional. Only to be used if you wish to install new

FW version on-site.

© Brüel & Kjær Vibro ● C107759.002 / V03 Page 7 of 22

Technical alterations reserved!

Brüel & Kjær Vibro │Instruction VCM-3 On-Site Commissioning

Initial Power Up test –Visual check

EN

UNRESTRICTED DOCUMENT

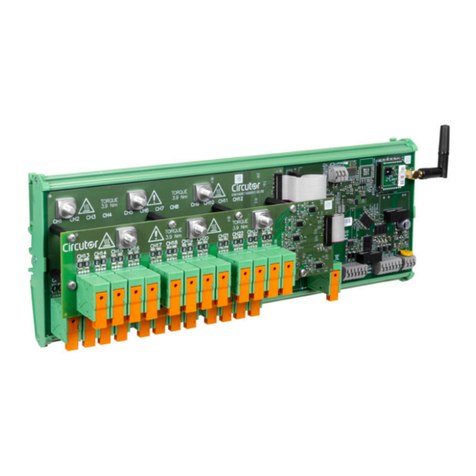

3 Initial Power Up test –Visual check

Purpose:

1. To check that the VCM-3 can boot up correctly

2. To check that sensors are wired correctly

3. To check that the speed sensor is working.

NOTE!

This visible check assumes that the VCM-3 is running the factory monitoring template.

Power Up

1

Apply power to the VCM-3

2

Wait until the boot procedure is complete.

When the Boot Status LED turns into green the boot procedure is complete.

All channels in the VCM-3 have been configured in the factory monitoring template. Therefore, you

will see a blue color LED on the AC/DC channels with no sensor connection.

After power up the VCM-3 front panel shall look like the picture below.

If the LED’s deviates from the description in the table below there is a problem with the VCM-3 or the

installation of the sensors. This shall be investigated before the commissioning procedure is

continued.

Page 8 of 22 © Brüel & Kjær Vibro ●C107759.002 / V03

Technical alterations reserved!

EN

UNRESTRICTED DOCUMENT

Initial LED status from factory

Inputs/Outputs/System and

associated LED color

Explanation

Network

Off –as the VCM-3 is not connected to any network (beside

RJ-45 connector)

Status: System

On –Blue, indicates that the VCM-3 is not connected to a

server in the condition monitoring centre.

Status: Template

The factory template is loaded and running.

Status: Online

No gateway IP address is defined, the VCM-3 is not connected

to the network

Boot Status

On-Green. This indicates the the VCM-3 has completed it’s

boot procedure correctly

DI/O

On –Green because Modbus is enabled in the factory

template.

DO

Off –as the digital output is not in use

DI

Off –as the digital input is not in use

AC/DC

On –Green, input channels which are wired to an

accelerometer. In this example channel 1 to 9.

AC/DC

On –Blue, input channels which are configured as constant

current source (CCS) accelerometers, but not wired to an

accelerometer.

AC/DC

(11 and 12)

On –Blue, input channels which are configured for an AS-247

MEMS sensor with 24 V supply, but not wired to a sensor.

Speed/DC

On –Green. Speed inputs shows green light as all Speed/DC

sensor inputs are enabled in the factory template.

If an input is connected to a speed sensor the LED will flash

between dark green and light green If the machine is rotating

slowly or you put a piece of metal in front of the mounted speed

sensor.

Speed/DC

4-20mA

On –Green, as all 4-20mA sensor inputs are enabled in the

factory template

© Brüel & Kjær Vibro ● C107759.002 / V03 Page 9 of 22

Technical alterations reserved!

Brüel & Kjær Vibro │Instruction VCM-3 On-Site Commissioning

Initial Power Up test –Visual check

EN

UNRESTRICTED DOCUMENT

3.1 Investigation of deviations in LED colors after initial power up

It is recommended to remedy any visible problems, if possible, before you proceed with the

remaining part of the commissioning procedure.

3.1.1 Sensor problems on connected sensors (signal inputs)

Color

Explanation

Off

Channel disabled

Green

Channel enabled, no errors

Red

Template error

Blue

Channel voltage out of defined range

Tacho out of range (for tacho channels)

Yellow (blinking)

Level 3 indication is controlled by the template (the blinking is

combined with red, green, or blue)

If there is an error indication on the channel LED it is important to know what type of sensor you are

working with. There are two types of sensors:

3.1.2 CCS (constant current supply) sensors

Color

Explanation

Blue

Sensor is connected correctly but it is outputting outside of the

allowed range.

Check the sensor’s calibration.

Check the allowed range in the template and the bias level in the tap

test.

Blue

Sensor is not connected.

Sensor is not connected correctly (S+ and S-/C interchanged).

Sensor is not grounded (S+ and S- are connected, but S- are not

connected to C).

Page 10 of 22 © Brüel & Kjær Vibro ●C107759.002 / V03

Technical alterations reserved!

EN

UNRESTRICTED DOCUMENT

3.1.3 Non-CCS sensors

Color

Explanation

Blue

Sensor is not connected.

Sensor is not connected correctly (S+ and S- interchanged).

Check the sensor’s calibration.

Check the allowed range in the template and the bias level in the tap

test.

Blue

For non-CCS sensors this is indicating a serious problem with the

sensor. If it is a tacho sensor that is outputting >25V you can safely

ignore this error, but in all other cases you should check the sensor.

3.1.4 VCM-3 hardware (device) problems

System LED

Color

Explanation

Green

Connected to backend

Yellow

Disconnected from backend (was previously connected)

Blue

Disconnected from backend

Red

Watchdog error/reboot imminent

White

Firmware is upgrading

Purple

System is sampling real-time

Cyan

System has stopped real-time sampling

Template LED

Color

Explanation

Green

Template loaded

Yellow

Template not loaded

Blue

Template error

Red

Fatal error (both template and fallback template failed)

Online LED

Color

Explanation

Green

Gateway pingable

Yellow

Factory settings

Blue

Gateway not pingable

Red

Configuration error / gateway not reachable (reachable before)

Dark blue

Reseting to default IP address

© Brüel & Kjær Vibro ● C107759.002 / V03 Page 11 of 22

Technical alterations reserved!

Brüel & Kjær Vibro │Instruction VCM-3 On-Site Commissioning

Initial Power Up test –Visual check

EN

UNRESTRICTED DOCUMENT

Device Status /

LED color

Explanation

Status: System

On –Red. Watchdog about to reboot the VCM-3

Action:

1. If watchdog reboot does not help, make a manual reboot. The reboot

activates some repair facilities.

2. If 1) does not help, then make an upgrade of the firmware. Refer to

the procedure in Appendix 2.

3. If 2) does not help the VCM-3 or the running template has a fault. Try

changing to the factory template. If that solves the problem the

template must be replaced or updated. If the problem is present with

the factory template –replace the unit..

Status: Template

On –Red. Fatal template error

Action:

1. Reboot the VCM-3 and check if the problem disappears. The reboot

activates some repair facilities.

2. If 1) does not help then make an upgrade of the firmware. Refer to

the procedure in Appendix 2.

3. If 2) does not help the VCM-3 has a fault. You cannot complete the

commissioning procedure. Exchange the VCM-3 with a spare unit.

Status: Online

On –Red. Either default gateway cannot be reached (but before) or network

has a configuration error. (Maybe the specified IP address is illegal)

Action:

1. Reboot the VCM-3 and check if the problem disappears. The reboot

activates some repair facilities.

2. If 1) does not help go to the Network configuration page and check.

Boot Status

On –Red. Unit is off and power is within specification. Ready to be turned on.

Action:

1. Push the Power Up/Down button but only with a short push. If this

turns the Boot Status into green the VCM-3 is OK.

2. If 1) does not help then reboot the VCM-3 and check if the problem

disappears. The reboot activates some repair facilities.

3. If 2) does not help the VCM-3 has a fault. You cannot complete the

commissioning procedure. Exchange the VCM-3 with a spare unit.

Page 12 of 22 © Brüel & Kjær Vibro ●C107759.002 / V03

Technical alterations reserved!

EN

UNRESTRICTED DOCUMENT

4 VCM-3 Homepage Commissioning Procedure

After the visible inspection check the on-site commissioning procedure shall be continued using the

functionality of the VCM-3 Homepage.

Via the Homepage the following steps shall be completed:

1. Check the VCM-3 firmware version

2. Check the Operational Status

3. Check the sensor bias voltages

4. Perform a Tap test of all accelerometers in order to check the correct mounting of the

accelerometers

5. Check the rotational speed sensor signal using a piece of metal

6. Configure the VCM-3 with the correct IP addresses and enable services

7. Save the commissioning report

8. Reboot the VCM-3 after completion

9. Inspect the VCM-3 front plate after reboot

4.1 Log into the VCM-3 Homepage

How to connect a laptop and perform the login.

1

Change the laptop network settings to match the ip range of the VCM-3. Factory default network

settings of VCM-3 are as follows:

•Netmask (subnet mask): 255.255.255.0

•VCM-3 Ipv4 address: 192.168.2.202

NOTE!

Brüel & Kjær Vibro recommends that to set the laptop to Ipv4 address

192.168.2.199, Netmask 255.255.255.0

2

Connect the laptop to one of the RJ45 ports of the VCM-3 unit using a LAN cable.

RJ45 cable connector.

3

Write the VCM-3 IP address in the browser. Ignore the security notifications and proceed to the

VCM-3 login page.

Table continued on next page…

© Brüel & Kjær Vibro ● C107759.002 / V03 Page 13 of 22

Technical alterations reserved!

Brüel & Kjær Vibro │Instruction VCM-3 On-Site Commissioning

VCM-3 Homepage Commissioning

Procedure

EN

UNRESTRICTED DOCUMENT

4

Use the following credentials:

Username: vcm_service

Password: VCM3-Service

4.2 Check the VCM-3 firmware version and update firmware

Check firmware version

1

After the login procedure is completed chack the firmware version number is located in the page

header.

2

If the firmware is version 1.14 or lower, the VCM-3 must be updated to a later version. Refer to the

procedure in Appendix 2. Initial (first) release firmware version is 1.15.

Page 14 of 22 © Brüel & Kjær Vibro ●C107759.002 / V03

Technical alterations reserved!

EN

UNRESTRICTED DOCUMENT

4.3 Check the Operational Status

NOTE!

This page is only available on VCM-3 with installed firmware version 1.15 or higher.

How to inspect the Operational Status page

1

After login the Operational Status page is shown. This page gives an overview of the present status

of the VCM-3. As a general rule the status indicators in the red boxes must have the status as

shown on the screen shot. Otherwise there is a problem with the VCM-3.

The other status indicators are dependent upon the state of the commissioning procedure.

2

If the status indicators in the red boxes shows a different result, try to reboot the VCM-3 and

inspect the Operational Status page again.

1. Reboot the VCM-3 and check if the problem disappears. The reboot activates some repair

facilities.

2. If 1.) does not help then make an upgrade of the firmware. Refer to the procedure in On-site

Commissioning instruction C107759.002 EN: Appendix 2.

3. If 2.) does not help the VCM-3 has a fault. Exchange the VCM-3 with a spare unit.

© Brüel & Kjær Vibro ● C107759.002 / V03 Page 15 of 22

Technical alterations reserved!

Brüel & Kjær Vibro │Instruction VCM-3 On-Site Commissioning

VCM-3 Homepage Commissioning

Procedure

EN

UNRESTRICTED DOCUMENT

4.4 Check bias voltages of sensors

Use the Commissioning Report feature to check the bias voltages of the connected sensors.

NOTE!

The Commissioning Report is only supported with an activated Factory Monitoring

Template, which is not to be exchanged with the Standard (Master) Monitoring

Template and/or the customized Monitoring Template created with the VCM-3 Editor

software.

View Commissioning Report

1

Select Commissioning Report from the VCM-3 Homepage menu

2

Inspect the report.

•The bias voltages (Level) of CCS sensor shall be between 11 and 14 Volts

•The bias voltages (Level) of the AS-247 MEMS sensor on Channel 11 and 12 (if present) shall

be between 1.5 and 3 Volt.

•Put a piece of metal in front of the rotational speed sensor. It shall show approximately 25 V.

The 50/60Hz noise shall be in the mV range

Page 16 of 22 © Brüel & Kjær Vibro ●C107759.002 / V03

Technical alterations reserved!

EN

UNRESTRICTED DOCUMENT

4.5 Make tap test of the accelerometers

With the tab test can check the signal from each of the connected accelerometers and the speed

sensor by using the Oscilloscope function of the VCM-3 Homepage. In addition, it can be checked

whether the sensors are connected correctly to the VCM-3 input channels.

NOTE!

The intended use of the Oscilloscope function is during commissioning to check the

input channel signal (raw sensor signal).

The Oscilloscope function should only be used with the factory monitoring template for

commissioning.

By using this function with other templates than the commissioning (factory monitoring)

template the Oscilloscope plot can freeze or the VCM-3 Homepage becomes

unresponsive.

When this condition occurs, the user usually has to call up another function on the

VCM-3 homepage and then return to the Oscilloscope view.

IMPORTANT NOTE!

The measurement functionality of the VCM-3 is not affected by this behavior! All

measurement functions of the VCM-3 hardware/firmware continue to run, alarm states

are registered and communication via MODBUS or OPC is maintained.

Select the Oscilloscope window on the VCM-3 Homepage

1

The oscilloscope shows the time waveform from all sensor signals. When tapping each of the

accelerometers you can check whether the respons from the accelerometer appears on the expected

channel. The update rate of the display can be adjusted so it is possible to tap a group of sensors in a

certain sequenceand then check the result afterwards.

Table continued on next page…

© Brüel & Kjær Vibro ● C107759.002 / V03 Page 17 of 22

Technical alterations reserved!

Brüel & Kjær Vibro │Instruction VCM-3 On-Site Commissioning

VCM-3 Homepage Commissioning

Procedure

EN

UNRESTRICTED DOCUMENT

2

Use the Oscilloscope function to check the sensor connections and that the sensor provides a valid

signal.

4.6 Configuration

IMPORTANT NOTE!

It is essential that this manual process is done correct, otherwise you may require an

extra visit to rectify the information.

Configure network and machine specification

Select the Commissioning-Configuration Page on the VCM-3 Homepage.

On the Commissioning –Configuration page –key in the network configuration

•Name: Enter a machine name

•Number: Enter a number of the machine

•IP Address

•Default Gateway

•Netmask

Remember to click Save Changes

Page 18 of 22 © Brüel & Kjær Vibro ●C107759.002 / V03

Technical alterations reserved!

EN

UNRESTRICTED DOCUMENT

4.7 Document the completed commissioning process

Use the Commissioning Report feature to document the final commissioning result.

IMPORTANT NOTE!

Send the commissioning reports to the back office (B&K Vibro Hotline) staff.

It is valuable information in case of problems with connections to the VCM-3.

View Commissioning Report

1

Select Commissioning Report from the VCM-3 Homepage menu

2

Download the Commissioning Report to the service PC

1

Save the report by clicking Save/Print at the bottom of the Commissioning Report page.

A print window is automatically opened. Select the save to PDF feature in the print window.

Save the report with a turbine name or number and the IP address. Then it is so it easy to recognize

again.

2

The saved Commissioning report contains:

•Machine Name

•Machine Number

•Firmware Version

•Serial Number of VCM-3

•IP Address

•MAC Address

•Default Gateway

•Netmask

•DNS Server

•Enabled services

•Active monitoring template

•Identification of the user

•Bias voltages and 50/60Hz noise.

© Brüel & Kjær Vibro ● C107759.002 / V03 Page 19 of 22

Technical alterations reserved!

Brüel & Kjær Vibro │Instruction VCM-3 On-Site Commissioning

VCM-3 Homepage Commissioning

Procedure

EN

UNRESTRICTED DOCUMENT

4.8 Completing on-site commissioning –visible check

IMPORTANT NOTE!

This visible check assumes that the VCM-3 is running the factory monitoring

template.

When commissioning has completed the VCM-3 front panel shall look like the picture below.

LED color

Explanation

Network

Flashing

On –flashing green. The LED on the connector where a LAN cable is connected flashes

green. The VCM-3 is connected to the network.

Status –System

On –Blue, indicates that the VCM-3 is not connected to a server in the condition

monitoring centre.

On- Green, indicates that the VCM-3 is connected to a server in the condition monitoring

centre.

Both states are valid depending upon the actual network state.

Status - System

Status - Template

The factory template is loaded and running.

Status - Online

A green color shows that the VCM-3 can ping the specified gateway. This tells that the

VCM-3 is integrated into the network setup.

Boot Status

On-Green. This indicates the the VCM-3 has completed it’s boot procedure

DI/O

On –Green, as Modbus is enabled in the factory template.

DO

Off –as the digital output is not in use.

DI

Off –as the digital input is not in use.

AC/DC

On –Green, input channels which are wired to an accelerometer. In this example

channel 1-9.

AC/DC

On –Blue, input channels which are configured as constant current source (CCS)

accelerometers, but not wired to an accelerometer.

AC/DC

On –Blue, input channels which are configured for an AS247 MEMS sensor with 24V

supply, but not wired to a sensor.

Speed/DC

On –Green, as all Speed/DC sensor inputs are enabled in the factory template

If the machine is rotating slowly or you put a piece of metal in front of the mounted speed

sensor, the corresponding LED will flash between light green and dark green.

Speed/DC

4-20mA

On –Green, as all 4-20mA sensor inputs are enabled in the factory template.

Table of contents

Other NSK Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Sealey

Sealey Professional AUTO SERVICE TA100 Instructions for use

ABB

ABB ScreenMaster RVG200 operating instructions

Circutor

Circutor STM-S12 instruction manual

PAC

PAC R6000S Operation manual

enviromental express

enviromental express oakton PD250 instruction manual

Emerson

Emerson Micro Motion 782791**B Series Safety instructions booklet