Spirax Sarco R1C User manual

Other Spirax Sarco Measuring Instrument manuals

Spirax Sarco

Spirax Sarco Colima Visco User manual

Spirax Sarco

Spirax Sarco Colima Visco User manual

Spirax Sarco

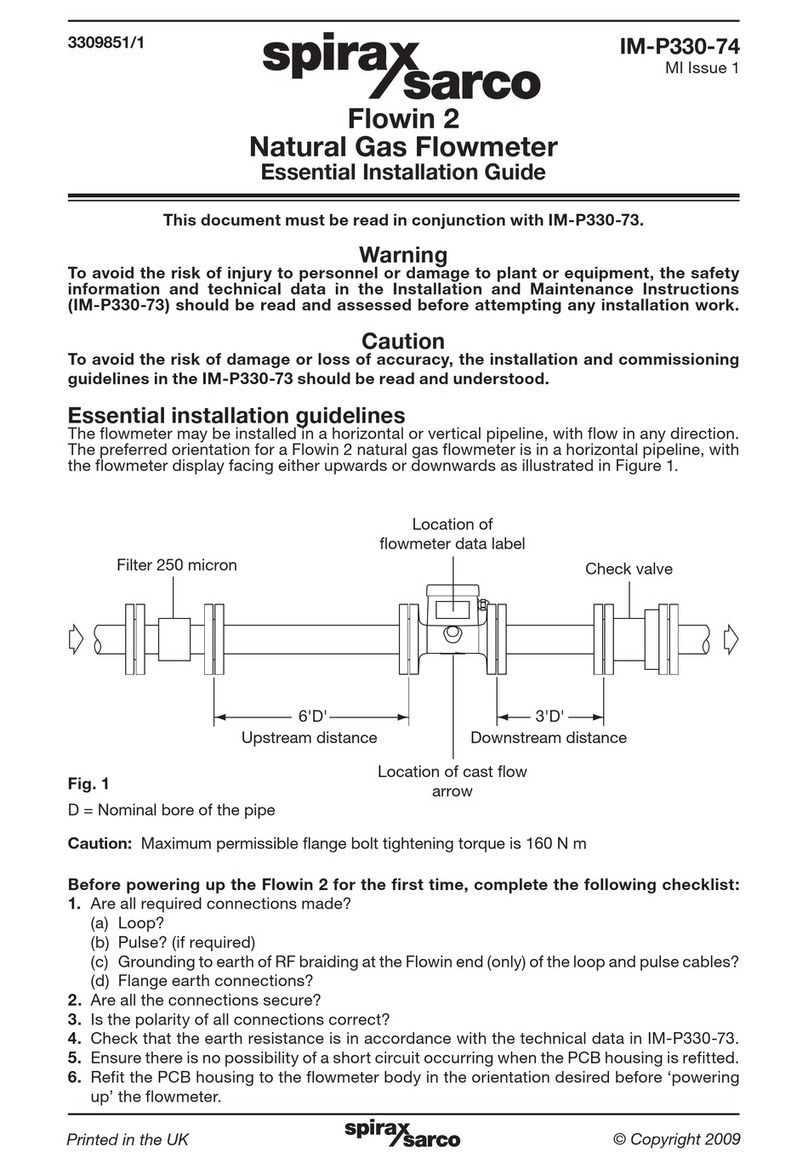

Spirax Sarco Flowin 2 User manual

Spirax Sarco

Spirax Sarco UTM20 Series User manual

Spirax Sarco

Spirax Sarco ILVA20 User manual

Spirax Sarco

Spirax Sarco ELM Assembly instructions

Spirax Sarco

Spirax Sarco RIM10 Series User manual

Spirax Sarco

Spirax Sarco STAPs User manual

Spirax Sarco

Spirax Sarco CP32 User manual

Spirax Sarco

Spirax Sarco ILVA20 User manual

Spirax Sarco

Spirax Sarco IFTGS14 User manual

Spirax Sarco

Spirax Sarco 2000 Series User manual

Spirax Sarco

Spirax Sarco MTL10 Inline User manual

Spirax Sarco

Spirax Sarco RIM20 User manual

Spirax Sarco

Spirax Sarco VLM30 User manual

Spirax Sarco

Spirax Sarco STAPs User manual

Spirax Sarco

Spirax Sarco TVA Series User manual

Spirax Sarco

Spirax Sarco MTI10 Insertion User manual

Spirax Sarco

Spirax Sarco DIVA User manual

Spirax Sarco

Spirax Sarco CP42 Technical specifications