ToOrderPartsCall1-888-702-5326-https://monsterfloorequipmentparts.com

4

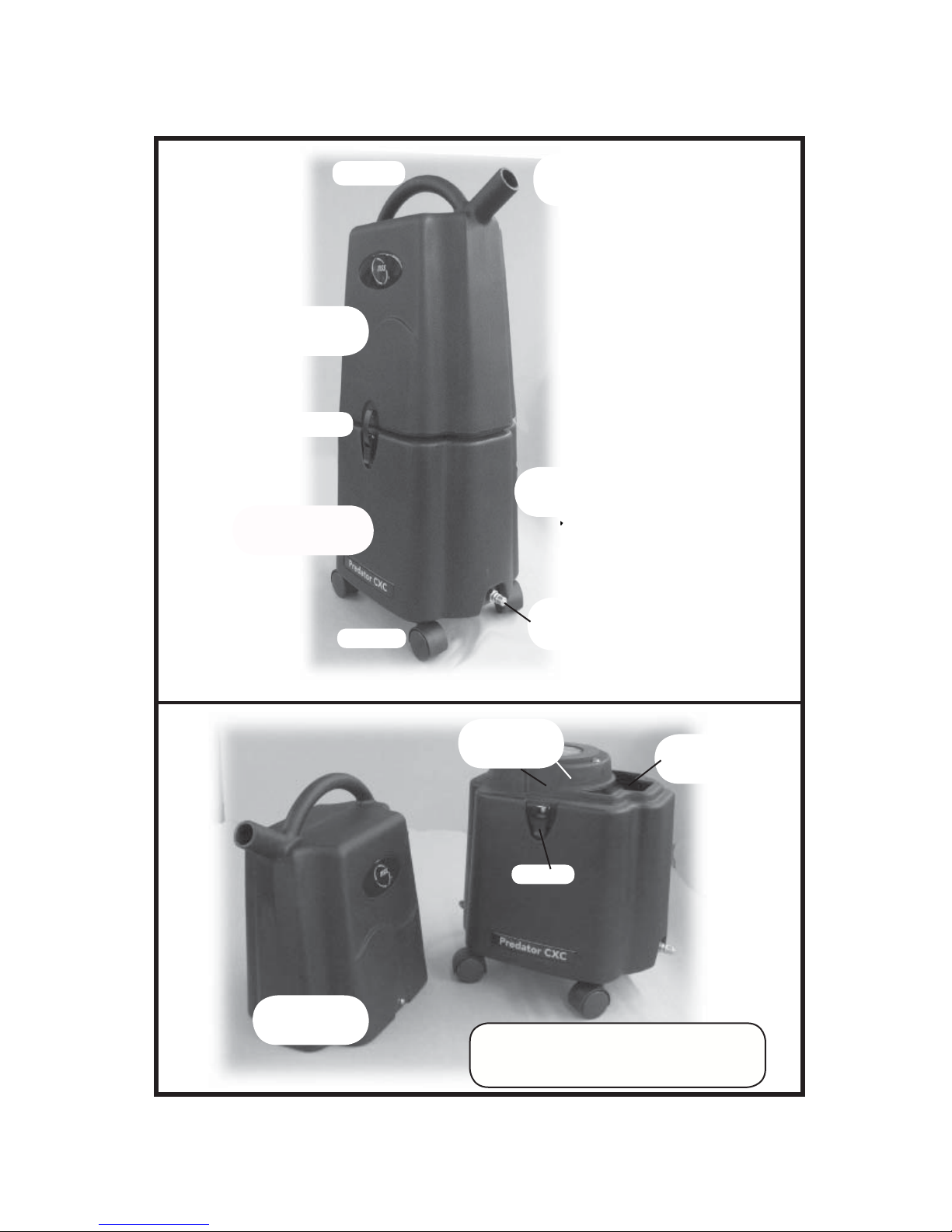

YOUR NEW MACHINE:

The manufacturer thoroughly tests every

machine it sells before it is packaged. When

you receive your new machine, examine the

packaging for signs of shipping damage.

Carefully unpack the machine and inspect it. If

you see evidence of damage to the container

or the contents, contact the freight carrier

immediately.

Additionally, ensure all parts and accessories

are present; if you notice anything missing,

contact your distributor without delay.

NORMAL USE:

The CXC & CXH Spotters are designed to

clean small areas like furniture, area rugs,

and spots in carpets. These machines are

not suited for cleaning the carpet in an

entire room.

CHEMICALS:

The use of clear water in the machine is

recommended, with the use of properly diluted

cleaner applied as a pre-spray on the area to

be cleaned; however, you may mix water and

cleaning chemicals in a bucket -- according to

directions on the chemical label -- and then

pour into the solution tank. If you chose to use

chemicals in the machine, always use a cleaner

with a pH as close to neutral as possible to

avoid premature wear of the pump, seals, and/

or other components. Damage caused by the

use of strong chemicals is not covered by the

warranty.

The use of powder chemicals is discouraged;

unless they are mixed very thoroughly and

rinsed out completely at the end of the job,

powdered cleanerscould causea build-upin the

pump, lines, heater and/or quick disconnects.

Any problem caused by a chemical build-up is

not covered by warranty.

If foaming occurs as you clean, use a defoamer,

either in the recovery tank or on the area being

cleaned, to prevent overflow which can cause

water damage.

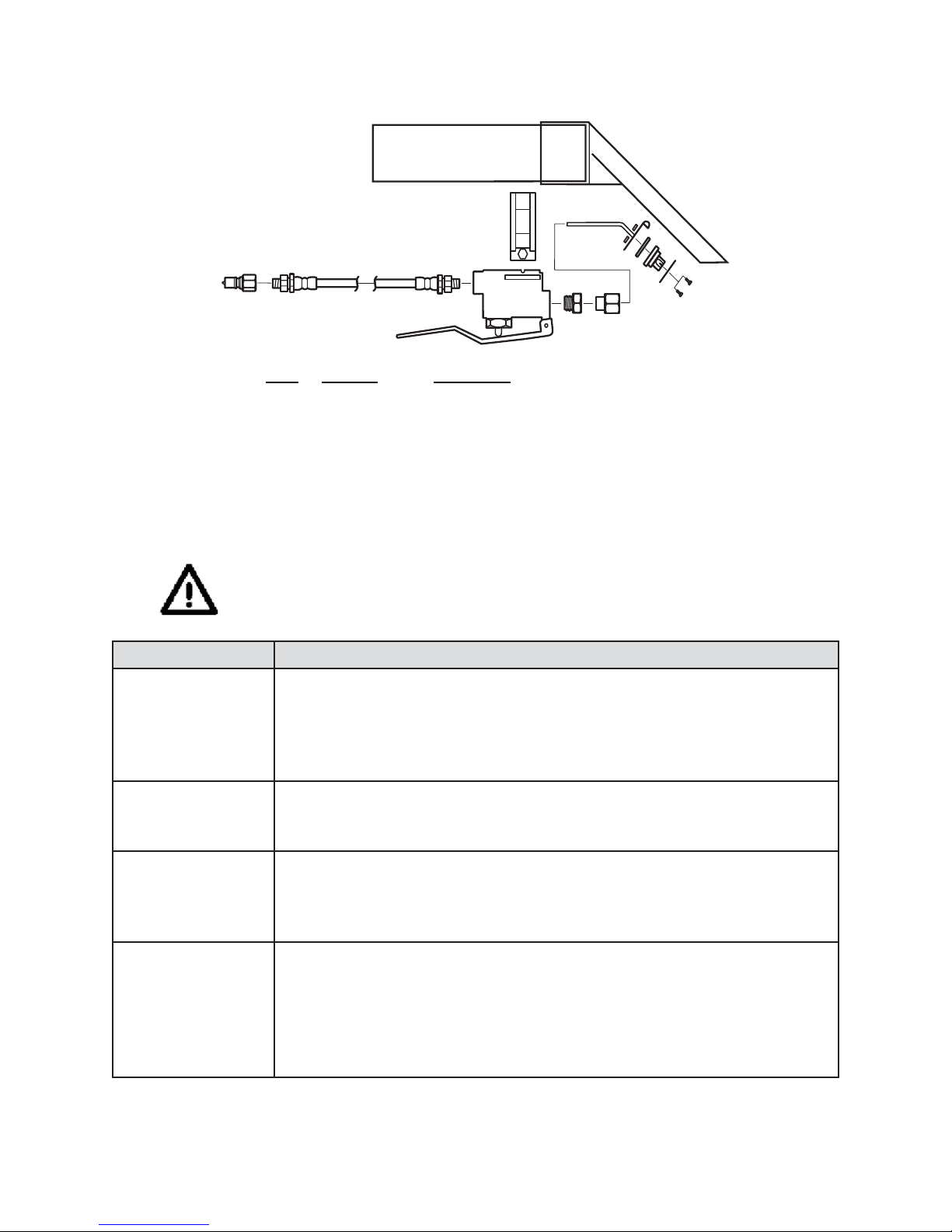

TOOLS & ACCESSORIES:

Use only manufacturer’s recommended

tools and accessories. The hand tool is

made from stainless steel and will provide

years of trouble-free use. If the spray valve

begins to leak or if the spray tip gets worn

and is no longer providing a nice even spray

pattern, order a replacement part from your

distributor.

The solution line and vacuum hose are made

of durable and long-lasting components and,

with proper care, they both should last for

years. Use a spray silicone to keep the quick

connect couplings moving freely.

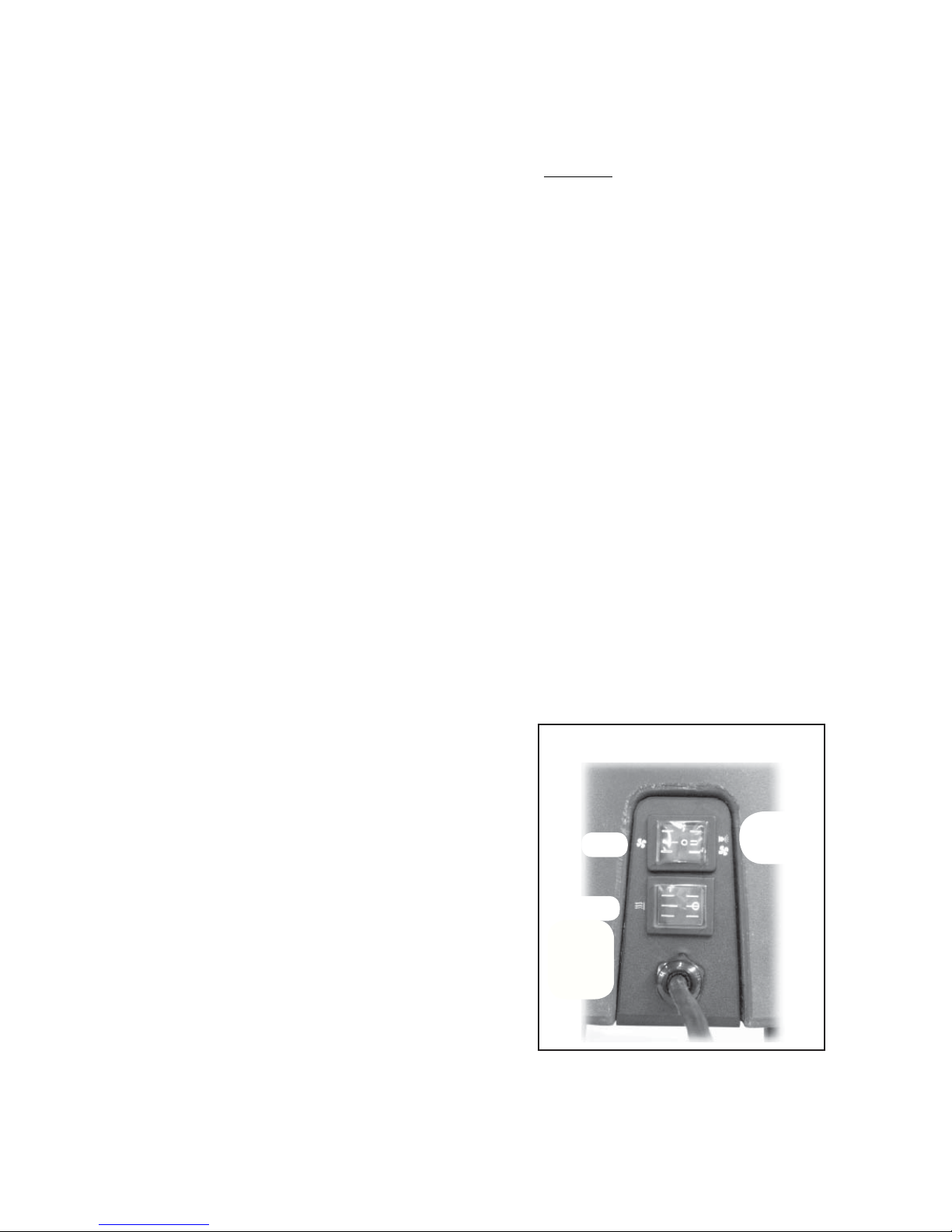

CARE & MAINTENANCE:

For optimum performance flush the machine

with clear water at the end of each working

day. Once a month, minimum, run a flushing

compound through the machine to break up

any mineral or chemical build-up that may have

formed from the use of hard water or chemicals.

The vacuum motor and the pump do not require

any scheduled maintenance; however, the

vacuum motor may require replacement brushes

after 700 - 1000 hours.

To maintain a professional image, clean the

body with an all purpose detergent, and protect

it with automobile interior polish. Lubricate the

wheels, castors, and quick disconnects with an

all purpose, silicone spray.