ESTD. 1958

www.nsw-india.com TERMS OF WARRANTY

8

NARANG SCIENTIFIC WORKS PVT. LTD. guarantee the

high quality and workmanship of each unit for a period

of one year subsequent to the date of delivery by the

company. During this period, faulty material will be

replaced free of charge. This guarantee does not extend

to components that are subject to wear and tear in the course of

normal operation or due to improper treatment /maintenance as per

instructions not followed.

TERMS OF WARRANTY

The manufacturer is only responsible for eects on the safety,

reliability and the performance of the instrument.

Installation, additions, adjustments, modications or repairs are

carried out by personnel authorized by the manufacturer.

The electrical installations within the room concerned satisfy the

requirements laid down by ISO/CE.

The appliance is used in full accordance with the instruction

manual which is solely a guide and no substitute for professional

training.The safe and eective use of this product largely

depends on the skill of the operator.We are not liable for nay

damages due to mishandling or improper and unauthorized use.

The company reserves the right to change technical

specications, designs without prior notice.

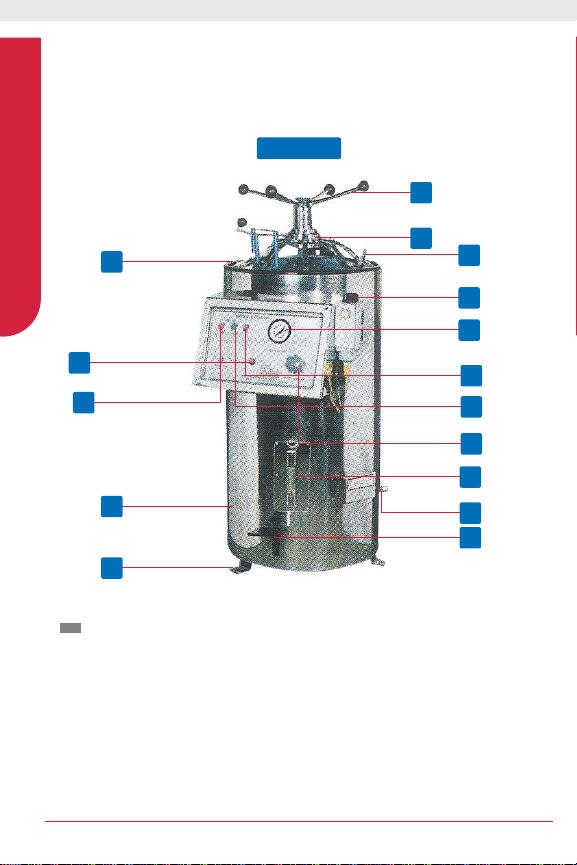

1

2

3

4

5

Note: In case you feel any kind of diculty please do not hesitate to contact us.

We shall be too pleased to assist you without any obligation. Our Instruments

are guaranteed for 12 months from the date of purchase.

Stamp:

WARRANTY CARD

Bill No.

Serial No.

Date of Purchase

Dealer Name