Table of Contents

NTEGRA Spectra Probe NanoLaboratory. SNOM

Measuring Head. Instruction Manual

Table of Contents

1. BASIC INFORMATION......................................................................................................................... 2

1.1. OVERVIEW........................................................................................................................................ 2

1.2. PRINCIPLE OF OPERATION ................................................................................................................ 2

1.3. DESIGN ............................................................................................................................................. 4

1.3.1. Optical Measuring Head................................................................................................... 5

1.3.2. Optical Tube...................................................................................................................... 9

1.3.3. Laser beam delivery system............................................................................................. 11

1.3.4. Photomultiplier Module .................................................................................................. 12

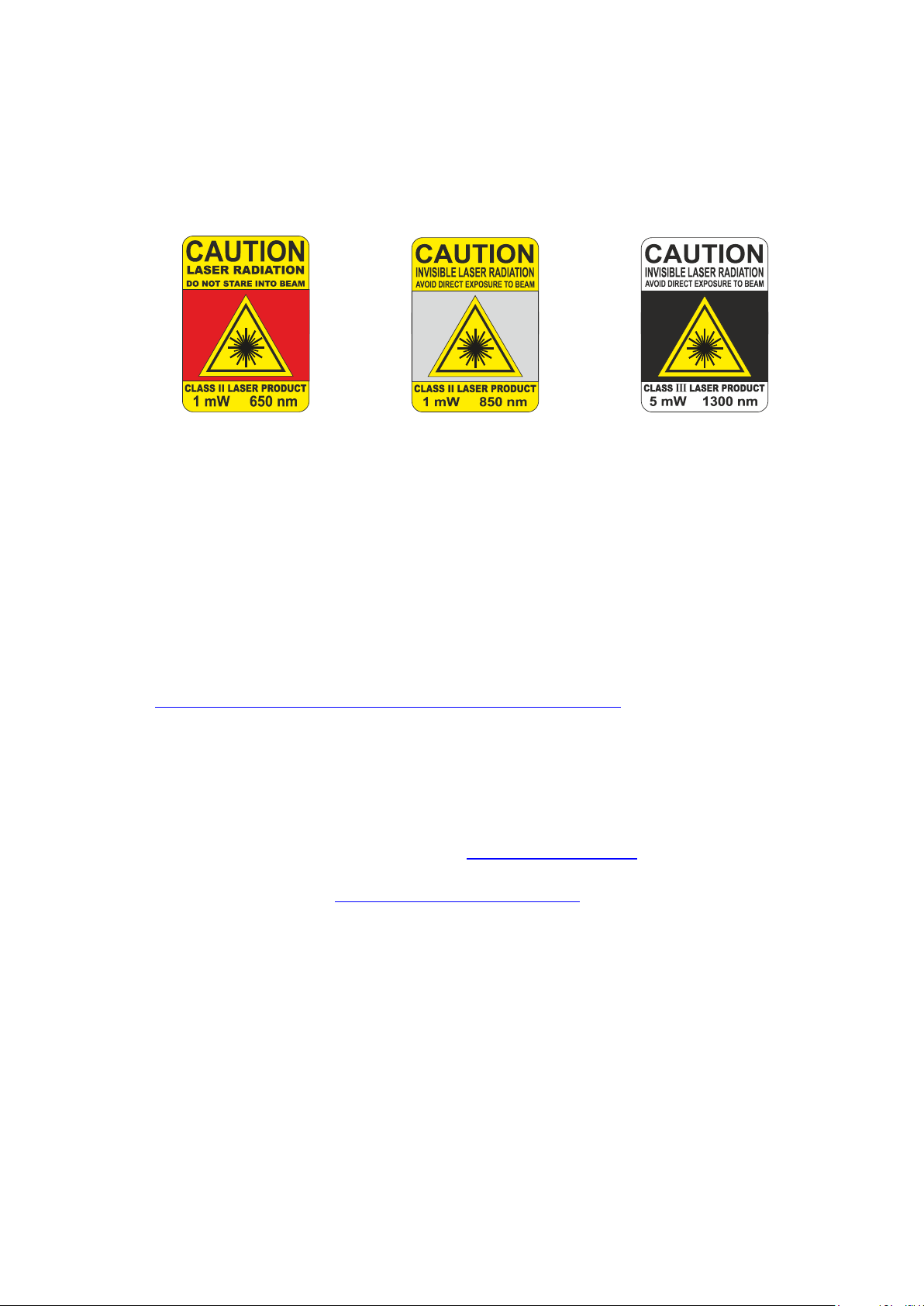

1.4. BASIC SAFETY MEASURES ............................................................................................................. 13

1.5. OPERATING CONDITIONS................................................................................................................ 15

1.6. STORAGE AND TRANSPORT INSTRUCTIONS .................................................................................... 16

2. ASSEMBLING OF THE SNOM MODULE........................................................................................ 17

2.1. EXCHANGING THE REPLACEABLE PANEL OF THE BASE UNIT ......................................................... 17

2.2. MOUNTING THE OPTICAL TUBE...................................................................................................... 18

2.3. MOUNTING THE LASER BEAM DELIVERY SYSTEM ........................................................................... 21

3. PREPARING FOR OPERATION........................................................................................................ 23

3.1. PREPARING AND INSTALLING THE SAMPLE..................................................................................... 23

3.2. PREPARING AND INSTALLING THE APERTURE PROBE ..................................................................... 26

3.3. INSTALLING THE PROBE HOLDER................................................................................................... 28

3.4. INSTALLING THE MEASURING HEAD .............................................................................................. 28

3.5. PRELIMINARY APPROACHING AND SELECTING SCAN AREA ........................................................... 30

3.6. PRIMARY ADJUSTING THE DETECTION CHANNEL........................................................................... 31

3.7. LAUNCHING THE CONTROL PROGRAM ........................................................................................... 33

3.8. ADJUSTING THE OPTICAL CANTILEVER DEFLECTION DETECTION SYSTEM .................................... 34

4. PERFORMING MEASUREMENTS ................................................................................................... 38

4.1. APPROACHING THE SAMPLE AND FINE ADJUSTING THE DETECTION CHANNEL.............................. 39

4.2. ADJUSTING THE DELIVERY CHANNEL ............................................................................................ 40

4.3. SCANNING ...................................................................................................................................... 47

4.4. SAVING DATA ................................................................................................................................ 50

4.5. FINISHING THE WORK .................................................................................................................... 51

1