General safety instructions

Thedeviceisbuiltaccordingtocurrentstate-of-the-arttechnologyandapplicableregulations.Thedevice

complieswiththe EUmachinerydirective,harmonisedstandards,Europeanstandardsortheapplicable

nationalstandards.Thisisconrmedwithamanufacturer’sdeclaration.

Relevant accident prevention regulations, generally accepted safety-related rules, EU guidelines, other

applicablestandardsandcountry-specicregulationsarealsoapplicable.

Becauselinearunitscanbeusedinsuchawiderangeofapplications,theultimateresponsibilityandliability

forappropriateuselieswiththeenduser.

Thisdevicecreatesanunavoidableresidualriskforpersonalinjuryandmaterialdamage.Forthisreason,

everyindividualwhoworksonthisdeviceassociatedwiththetransport,assembly,operating,maintenance

and repair of the device, must receive instruction and understand the potential dangers. The operating

instructionsmustbeunderstoodandobserved.

Inaddition,actuatingequipmentposesariskofinjuryduetorotatingorotherwisemovingcomponents.Due

tomovingcarriages,operationallinearaxesparticularlyposeanincreasedcrushinghazard,especiallyin

connectionwithendpositiondampersandlimitswitches.Theusermustmaketheseresidualrisksknown

withsignsorwrittencodesofconduct.Alternative,theusercaneliminateorexcludetheseresidualrisksto

thegreatestextentpossiblebyemployingappropriateconstructivemeasures.

Thenoiselevelcanincreaseathighspeeds,specialapplicationsandataccumulationofmorenoisesources.

Theusermusttaketheappropriateprotectivemeasures.

Linearunitstart-upisprohibiteduntilitcanbeestablishedthatthemachineorsysteminwhichitismounted

conformstoEUmachinery directives,harmonisedstandards,Europeanstandardsorapplicablenational

standards.

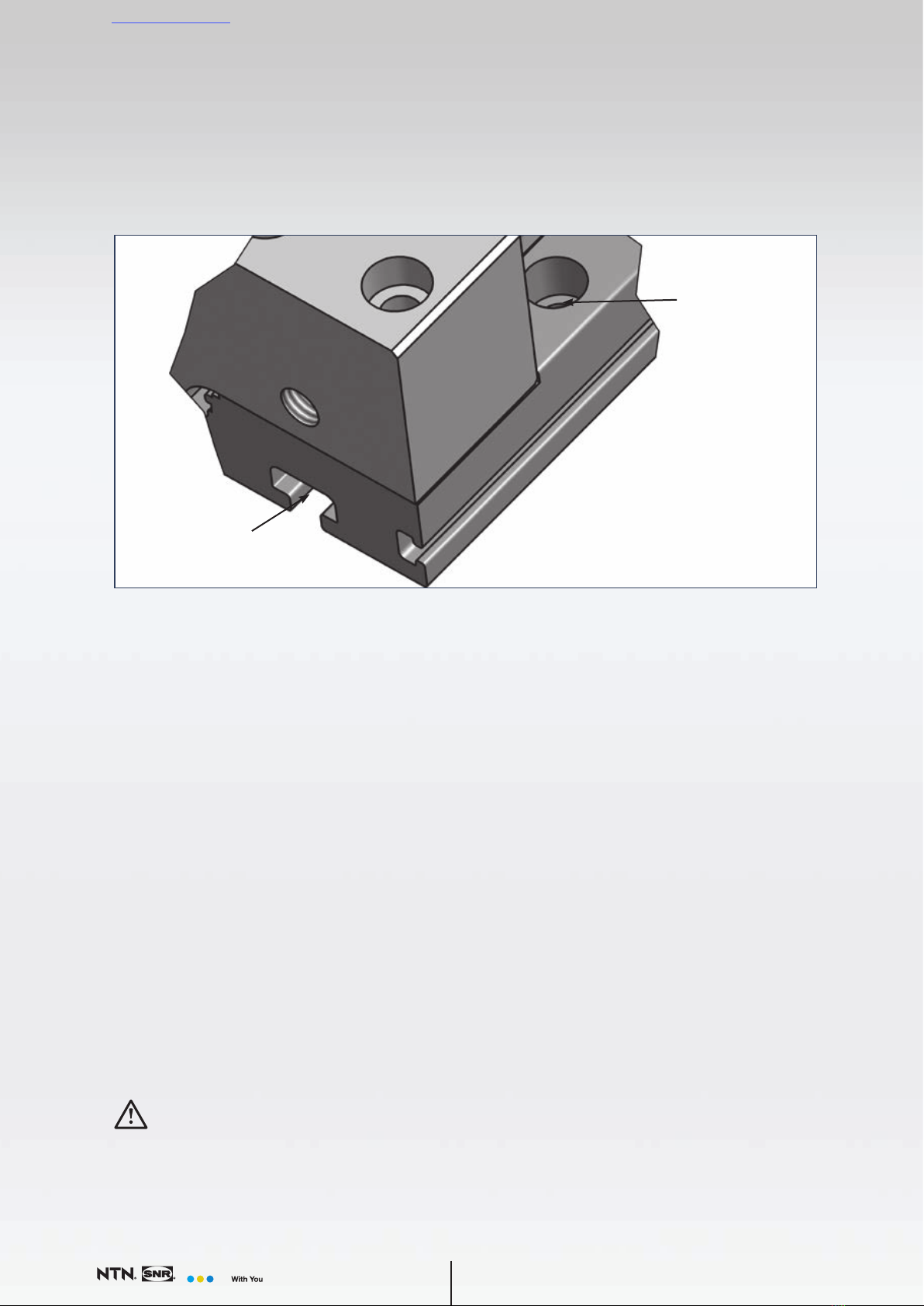

Intended use

NTN-SNR linear axes and NTN-SNR linear tables are fundamentally designated for linear movement as

occursduringpositioning,synchronisation,transport,palletising,loading,unloading,clamping,tightening,

testing, measuring, handling and manipulating components or tools. Type-specic load data from the

relevantcataloguedocumentationand/orNTN-SNRsupplementarytechnicalcalculationsmustbeobserved.

Furthermore,anoperatingtemperaturebetween–10°Cto+40°Cmustbeadheredto.

Alternativeorexcessiveuseisconsideredimproperuse.Themanufacturerassumesnoliabilityforresulting

damages.Theuserbearssoleresponsibilityforallrisks.

Thelinearaxismayonlybeoperatedandservicedbyindividualsfamiliarwiththeaxisandwhohavebeen

instructedinthedangers.

Specialprovisionscanbemadeforapplications(asexamplefoodindustry,cleanroometc.)whichdeviate

fromthestandardmodications.

Safety

6