8

25. 01. 23. Document Number 671856

Nuaire | Western Industrial Estate | Caerphilly | CF83 1NA | nuaire.co.uk

MRXBOXAB-ECO(3/5)-(SC/SW)Installation Manual

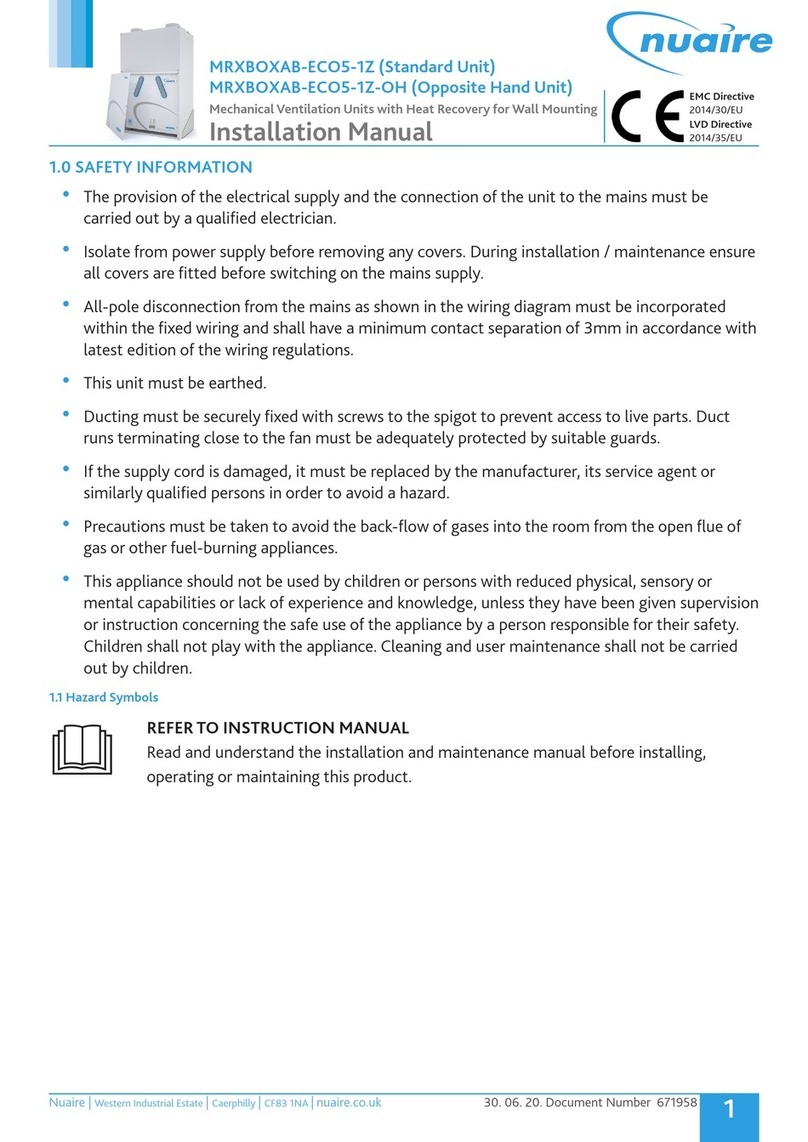

5.0 COMMISSIONING

The filters fitted inside the unit are protected with a plastic film.

Prior to commissioning remove the covers (Figures 20 & 21), take

off the film and replace.

1. For the required air flow rates please refer to the design specification

for the property, follow 3.7, or refer to appropriate building

regulation (see section 3.6)

2. The unit is supplied with independent control for both normal and

boost airflows (Figure 19).

3. Correct commissioning is essential to ensure the ventilation air flow

rates are met. It also ensures the unit is not over ventilating and

causing excessive power consumption.

4. Commissioning should be carried out in accordance with

appropriate building regulation (see section 3.6). A calibrated

moving vane anemometer and hood will be required to carry out

commissioning.

5. Adjustment valves should be locked in place to prevent further

adjustment.

6. Once commissioned the home owner / tenant should be informed

that the unit should not be adjusted as it will have a detrimental

effect on the indoor air quality and could result in condensation and

mould growth. The clear panel covering the control has an adhesive

panel which should be exposed and sealed post commissioning to

prevent tampering.

7. Speed 1 is limited to never exceed speed 2, when commissioning

speed 2 should always be set first.

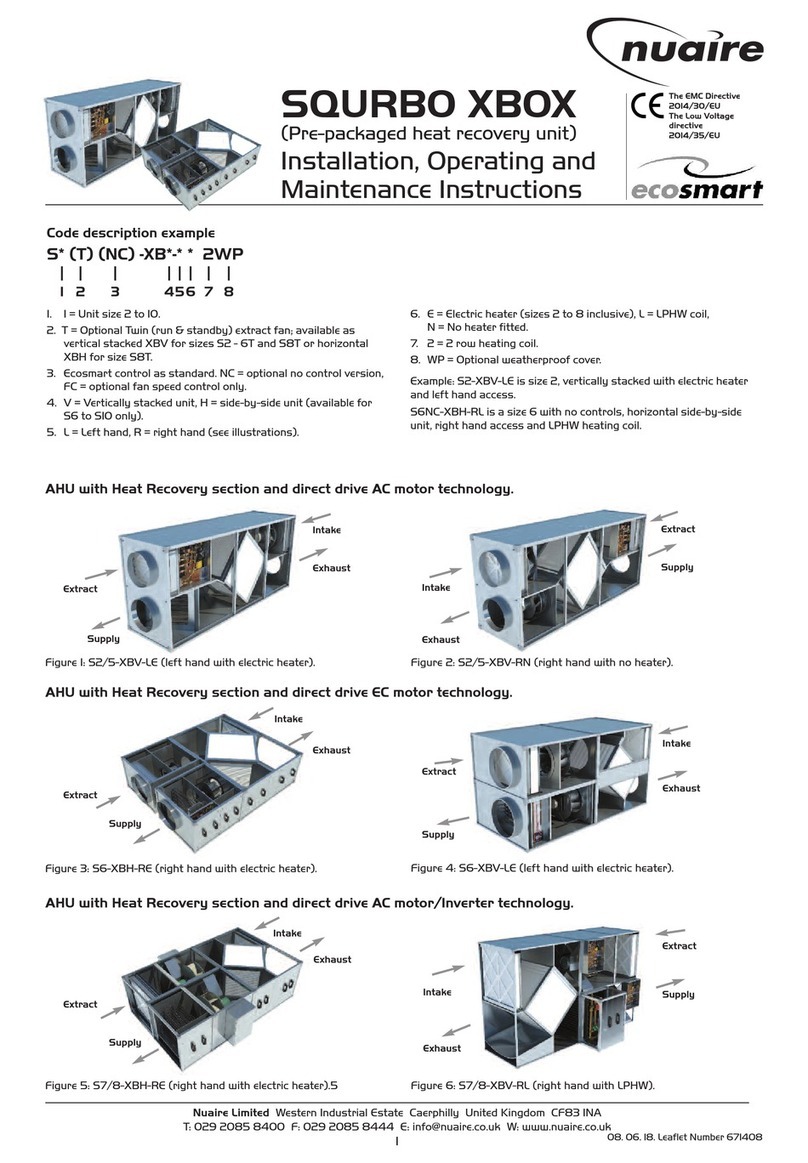

19 Unit Control On Front Panel (Standard Configuration Only)

+

-

Post commissioning remove

adhesive backing and seal

Power Fan

Failure

+

-

Ventilation Controls

-

+

+

-

+

-

Speed 1

-

+

Speed 2 Speed 3

Supply Extract Supply Extract Supply Extract

Humidity adjustment

5.1 Humidity Adjustment (AB unit only).

This product contains an internal humidity sensor fitted into the air-

flow extracting from the wet rooms. When the unit senses that the

humidity exceeds the set point the unit will boost to that set by the

commissioned boost speed. The set point can be found on the front

of the unit (Figure 19) and is at its least sensitive when turned fully

clockwise. Note that the sensor is measuring humidity from all the wet

rooms at the same time and should not be relied on to solely boost the

unit. Additional switch should be used local to the wet rooms (Section

4.3.3).

5.2 Status Indication

The status of the unit is indicated by a series of LED’s on the front cover.

The variants are listed below.

The display on the unit control panel will not indicate when a

higher speed setting has been triggered by an external source, such

as an ES-PIR2 etc.

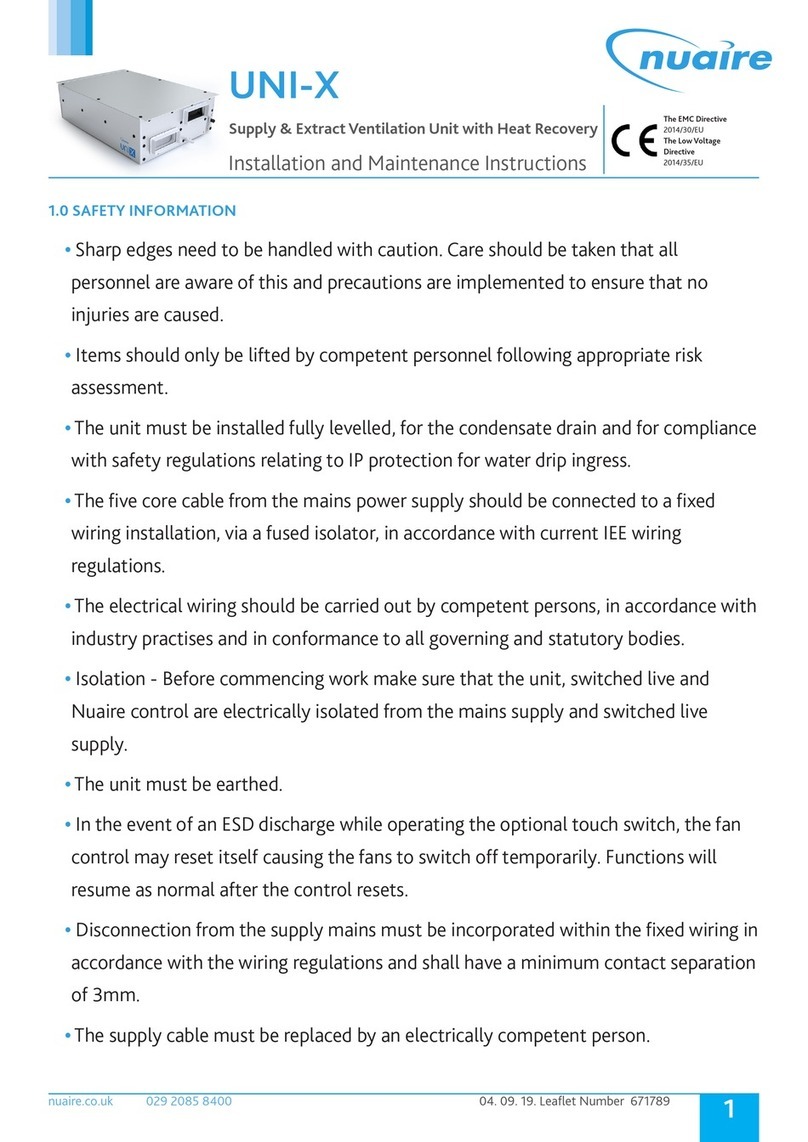

20 Unit Control On Front Panel (Standard Configuration Only)

HX Bypass

(AB units only)

Speed 1

Speed 2

Speed 3

Supply Fan Fault

Extract Fan Fault

Frost Protection

Filter Change

5.3 Integral Automatic HX Bypass

Intake and extract temperatures are monitored at the point the

airflows enter the unit, if the range falls within the set parameters the

bypass damper is opened automatically to target an indoor comfort

temperature all year round.

5.4 Summer / Winter Switch

When the switch position is set to Summer the integral automatic

summer bypass is fully operational, in the alternative Winter position

the HX bypass is disabled to ensure the unit is constantly in heat

recovery mode.

5.5 Speed 3 Operation (SW Units Only)

Speed 3 will be non-operational if the intake temperature is greater

than the extract temperature.

5.6 Frost Protection

In the event of the intake air temperature at the unit dropping below

the predetermined set point (-5°C as standard) the supply fan will

reduce to minimum speed, once the temperature rises above the set

point the fan will return to its commissioned speed.

Frost protection will only activate after ten days of continuous run

time. If commissioning of the unit is outside of this time frame please

notify the after sales department prior to site visit.

6.0 MAINTENANCE

It is important that maintenance checks are recorded and that the

schedule is always adhered to, in all cases, the previous report should

be referred to.

6.1 Filters

Filters are to be inspected every 6 months and replaced every 12

months (or sooner if required). Failure to do so may impair the

performance and energy efficiency of this unit. A flashing LED

(Section 5.2) will indicate that a filter change is required. This indication

repeats every 12 months and will turn off automatically after 5 Days.

Remove the filter covers on the front panel of the unit by gripping the

two circular tabs either end of the filter covers and pulling away from

the unit. The filter can now be extracted by pulling the black removal

loop on the front edge of the filter. Once the filters have been inspected

return or replace them as necessary.