1

1. INTRODUCTION

This installation guide is for the Thermostatic Sequential Shower Valve.

It covers the installation, maintenance and operation of the Shower

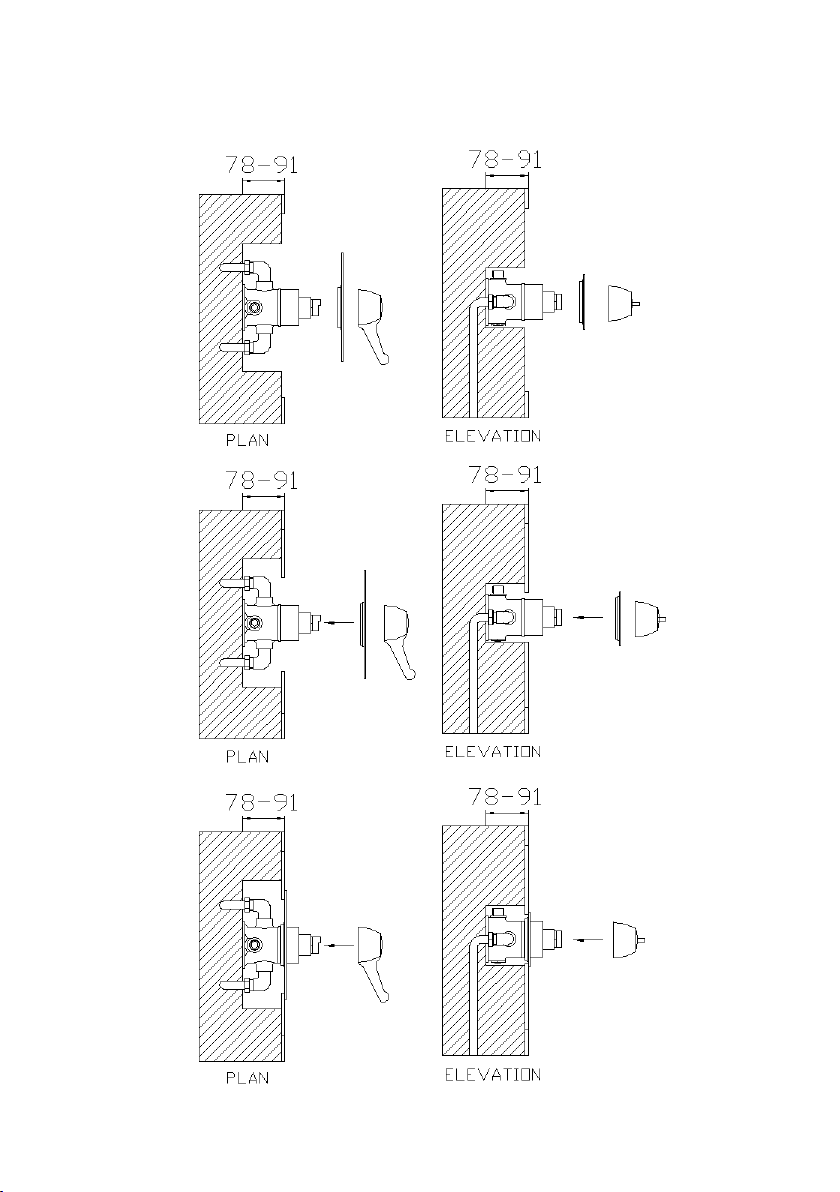

valve. This valve comes either as an Exposed Type Valve or a Concealed

Type Valve. There are different handle and plate types for the valves

depending on which valve was supplied.

The Thermostatic Shower Valve is a sequential valve, for showering

and is thermostatically regulated by a wax element. It is designed to

provide a flow of water at a safe temperature when installed as

described in this manual. The shower valve is suitable for both low and

high pressure installations. The valve is suitable, without modification,

for all types of installation, including pumped gravity systems, mains

pressure and combination boilers.

SAFETY

We recommend that this product is fitted by a fully qualified installer.

The installation must comply with all current water regulations.

Please note: This valve MUST be commissioned on site to suit site

conditions.

In order for this product to operate as designed it must be installed,

commissioned and maintained as stated in this manual.