O Signal Levels and Insertion Loss

The signal levels o both outputs are approximately 8dB lower in signal level than the input.

This means a 5V peak input signal will be lowered to around 2V peak. This reduction allows

the output audio signal more space to rapidly increase in volume, which it may do under

certain conditions, without any signi icant risk o clipping distortion.

When the module's eedback control is at its minimum value the delayed output's signal level

pretty much ollows that o the input. There are no surprises. However, increasing amounts o

eedback, both negative and positive, can produce massive changes in output signal level. The

actual peak output level is hard to predict as it can change with the harmonic structure o the

input signal, the undamental requency o the input signal, the delay time selected and the

modulation signals used. This rapid change in volume at certain requencies is a distinctive

part o the langing sound.

Any 5U modular system is powered rom +/-15V so the maximum signal output o any

module cannot be more than +/-15V. In practice it actually works out somewhat less than this

and outputs o over +/-13V are unlikely. I the output wants to be above this value, but the

module cannot produce it, then the output clips. This means the module does what it is

supposed to do up to +/-13V and then any desired output greater than that is clipped at +/-

13V and goes no urther. This abrupt lattening o the top and bottom o wave orms creates

distortion and is generally not wanted.

The Flanger module is quite capable, when eedback is applied, to produce signal levels ar

greater than what goes in. I the output matched the input per ectly, ie. 5V peak ended up as

5V peak with no eedback, then when eedback was applied the output could easily try to

exceed the +/-13V. By lowering the nominal output level to approximately 2V peak the output

can rise by over six times be ore clipping sets in.

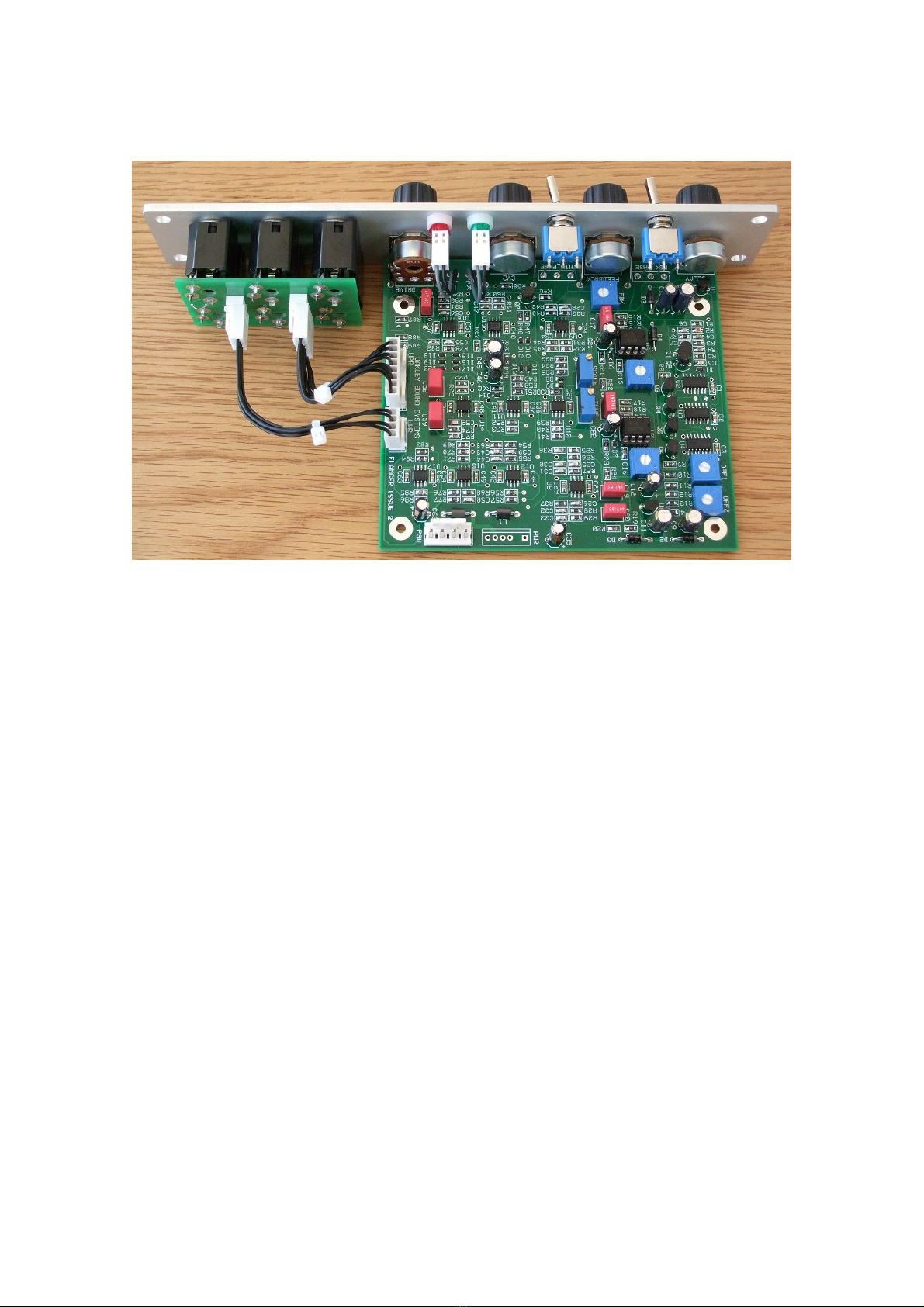

The two signal activity LEDs both monitor the signal level going into the BBD devices. The

module is calibrated so that the red LED will only light when the BBD audio driver circuitry

starts to overdrive. Keeping a signal under this level will help keep the signal as clean as

possible. It is, however, still possible, under certain conditions, or the output stages o the

module to distort. This should be obvious to the user as output stage clipping can normally be

heard. Clipping does not damage the module and some users may ind the sound appealing.

When the delay time is very short the signal running through the BBD devices is not passed

through as e iciently as it is when the delay times are longer. Engineers say that the insertion

loss through the BBD increases at higher clock requencies. The upshot o this is that you may

notice a small volume drop as delay times are shortened. While this has no real detrimental

e ect, especially or chorus and pitch shi ting e ects, it does reduce the signal level available

or eedback. At very high levels o eedback, that is, close to or at oscillation, and with very

short delay times you will notice that the langing e ect is not as pronounced. In practice this

means that the position o the eedback control is important to getting the right sound at the

desired delay time.

8