39

- GB -

Table of Contents

1Information about these operating instructions.................................................................................41

1.1 Symbols used in these instructions ..........................................................................................41

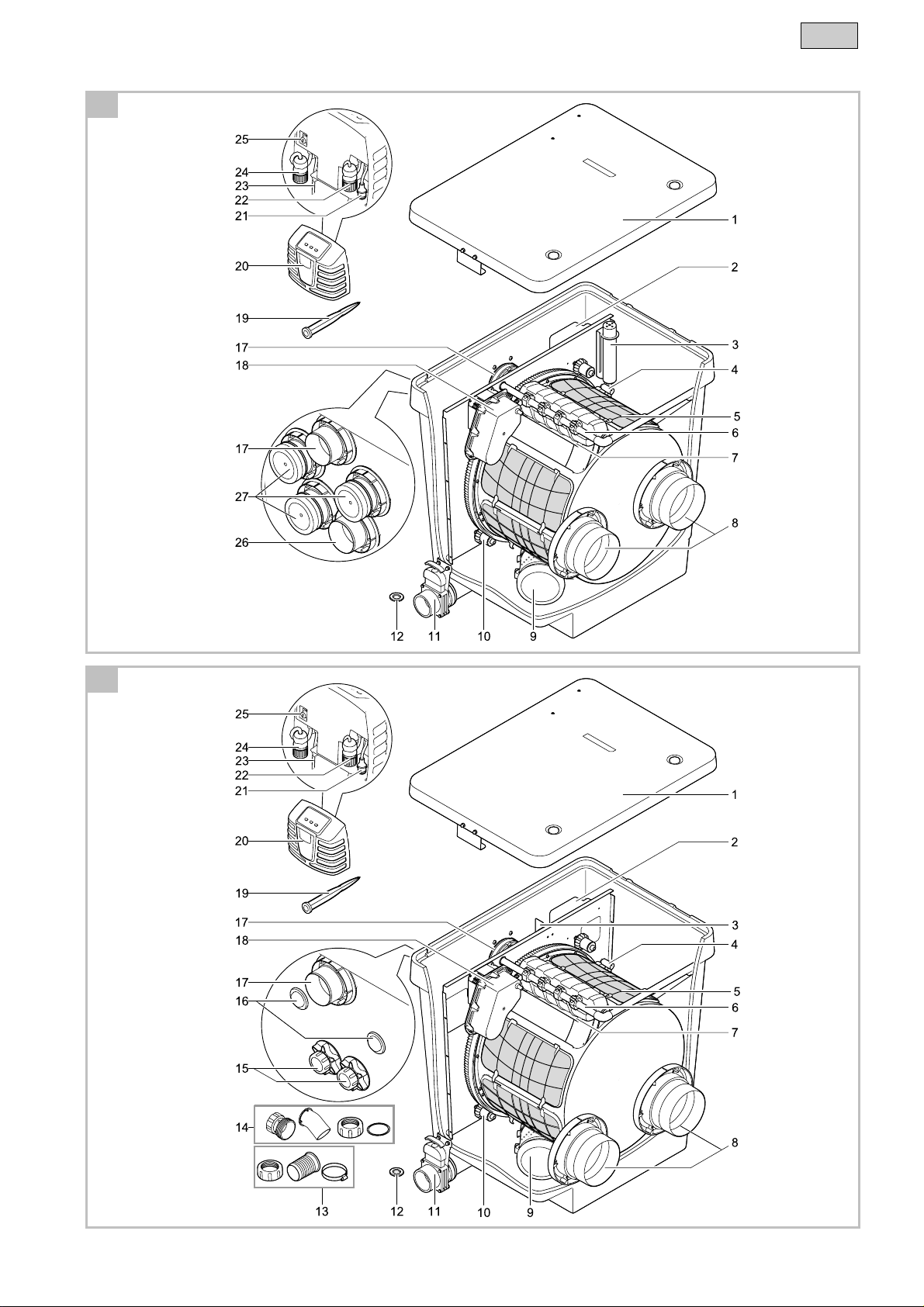

2Scope of delivery...............................................................................................................................41

3Product Description...........................................................................................................................42

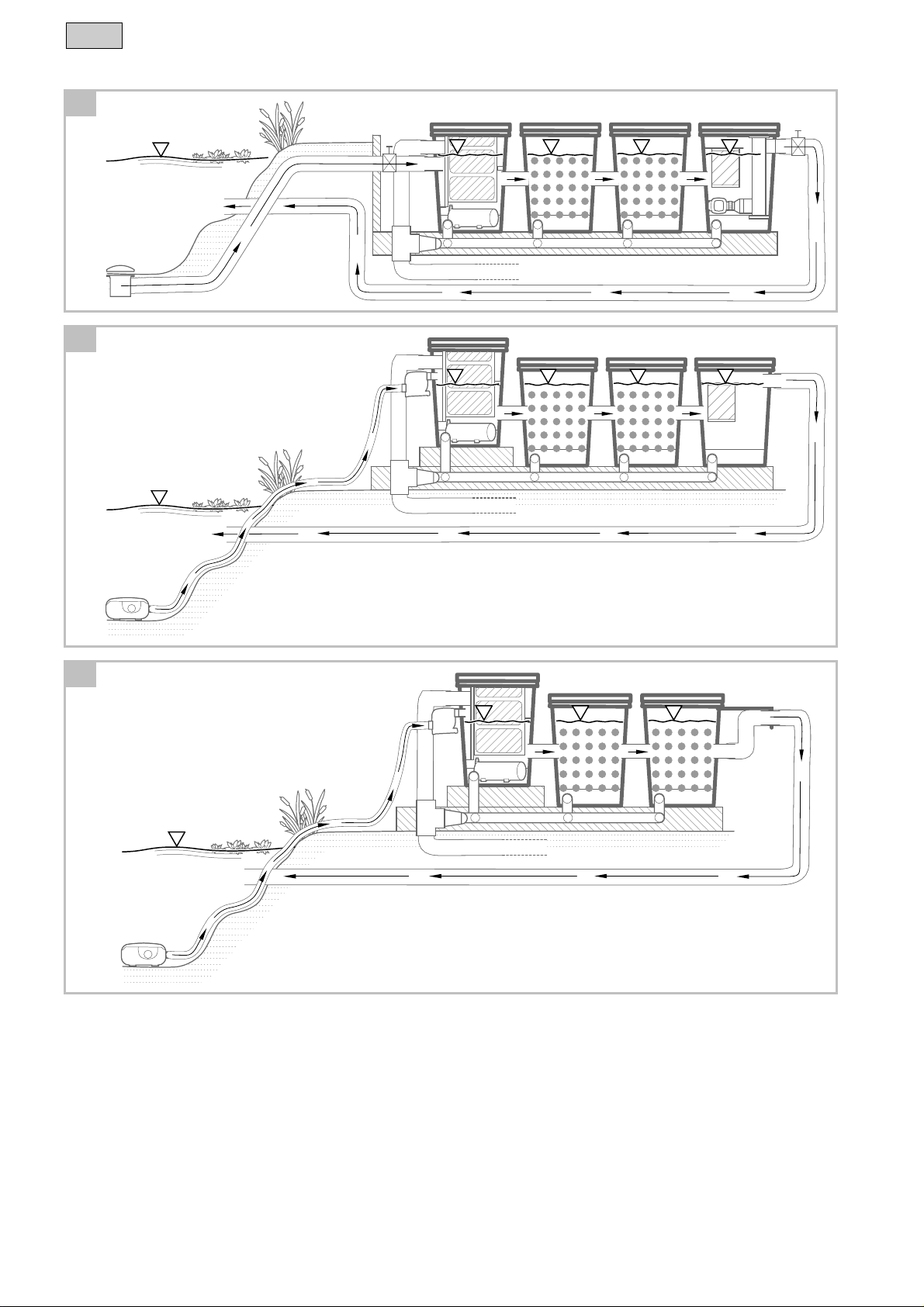

3.1 Gravity fed system....................................................................................................................42

3.2 Pump fed system......................................................................................................................42

3.3 Unit configuration......................................................................................................................43

3.4 Function description..................................................................................................................44

3.5 Intended use.............................................................................................................................44

4Safety information.............................................................................................................................44

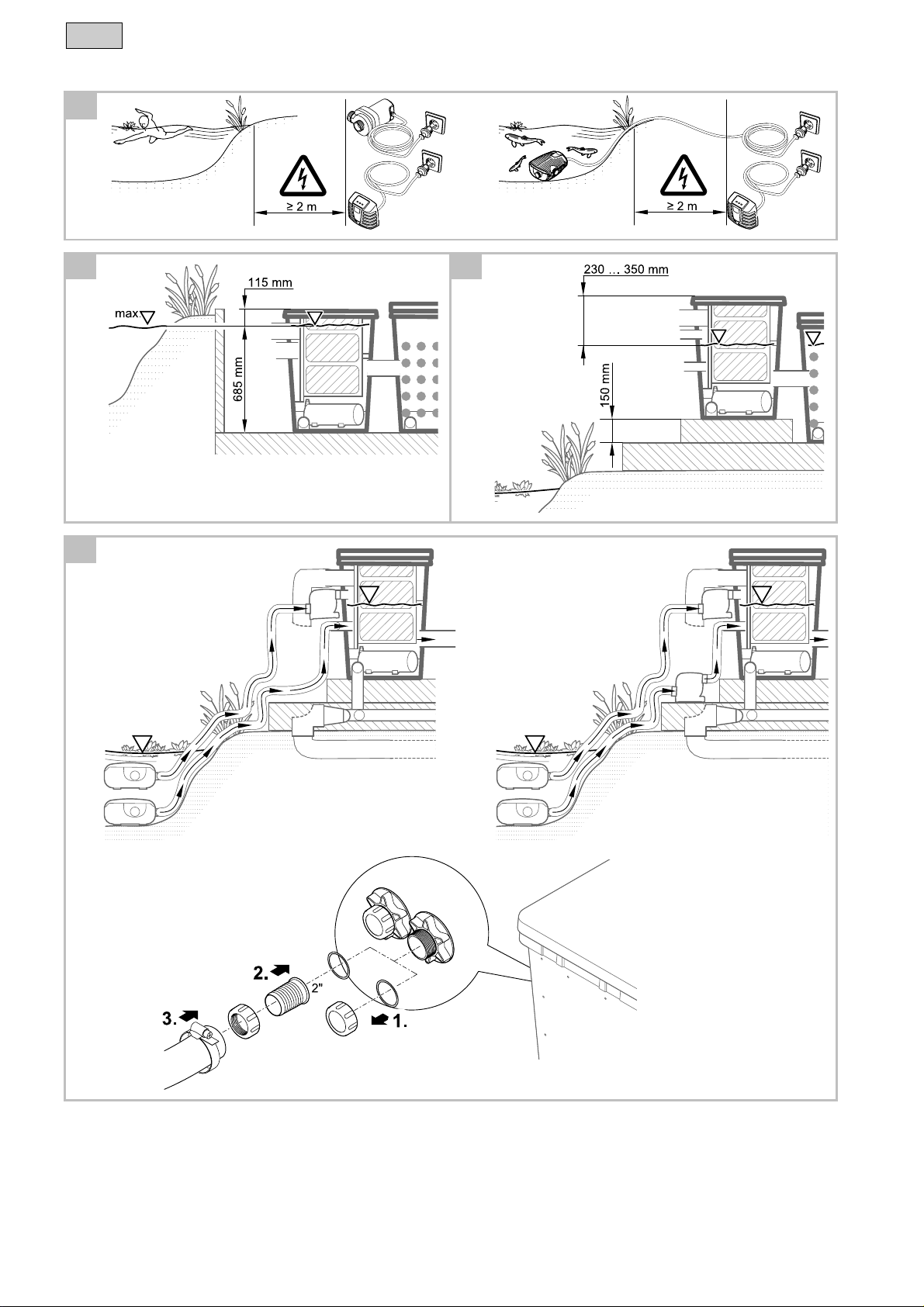

4.1 Hazards encountered by the combination of water and electricity...........................................44

4.2 Danger for persons with pacemakers.......................................................................................44

4.3 Correct electrical installation.....................................................................................................45

4.4 Safe operation...........................................................................................................................45

5Installation and connection................................................................................................................46

5.1 Installation planning..................................................................................................................46

5.1.1 Gravity fed system........................................................................................................47

5.1.2 Pump fed system..........................................................................................................47

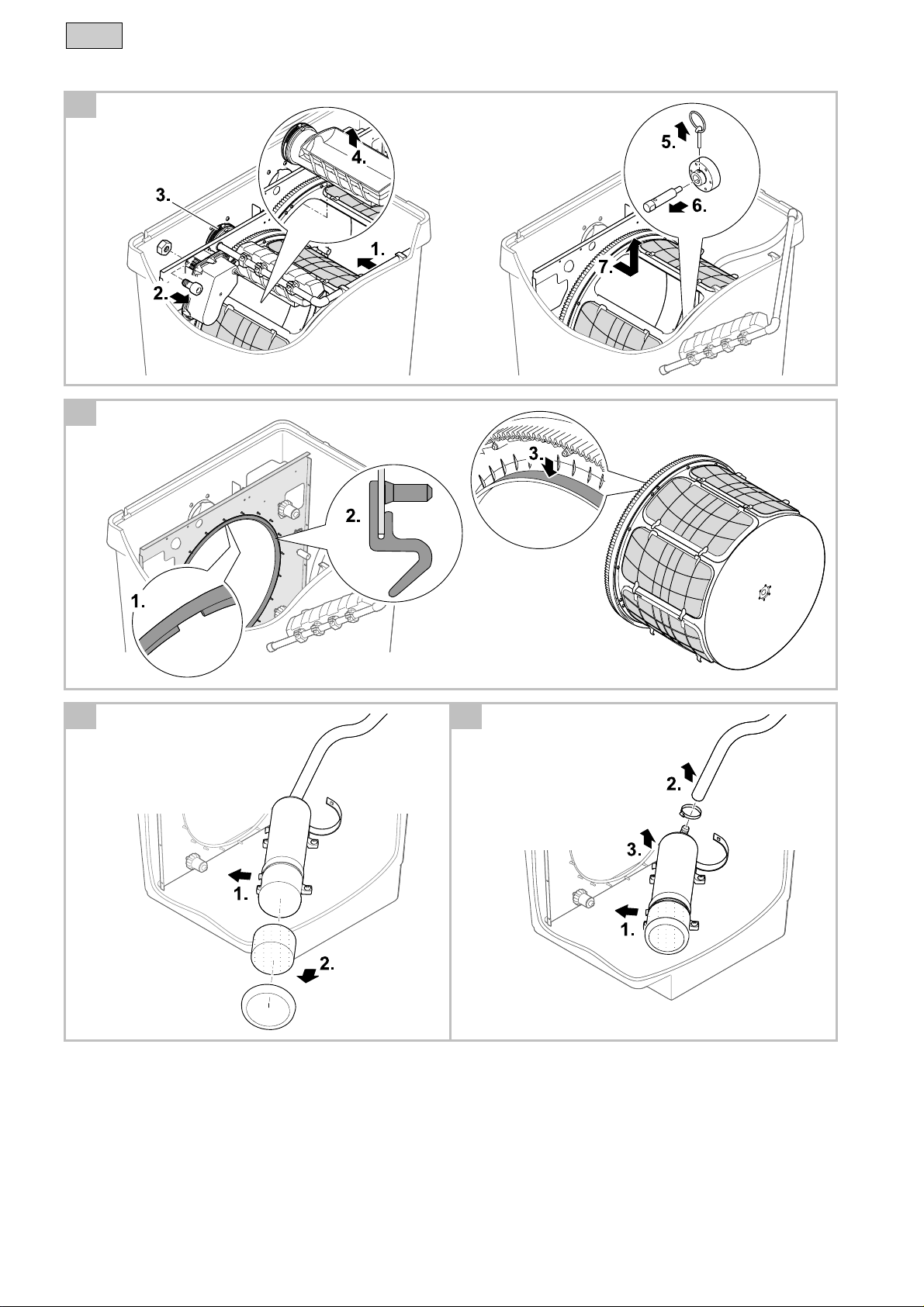

5.2 Connecting the drum filter.........................................................................................................48

5.2.1 Information regarding pipes..........................................................................................48

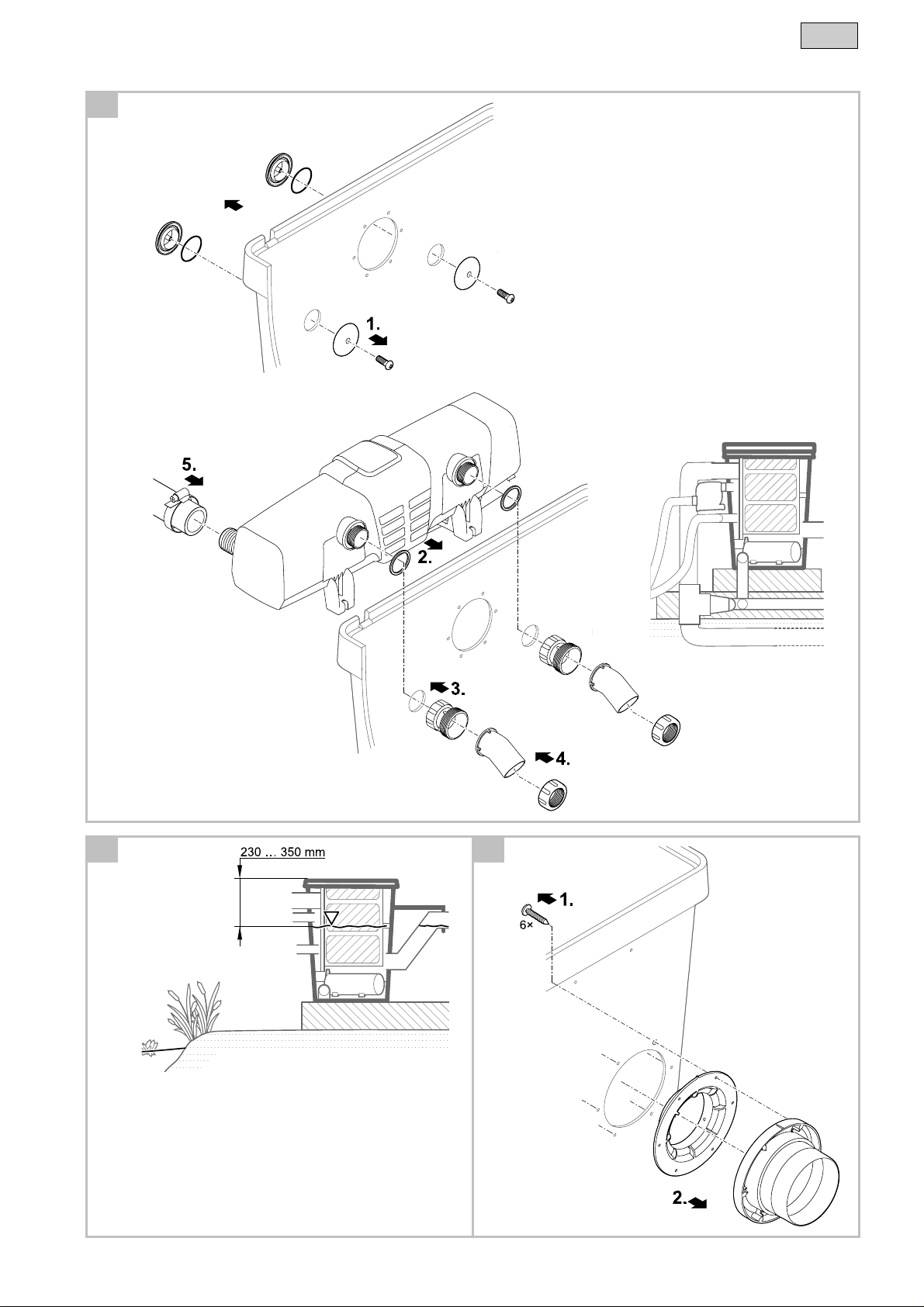

5.2.2 Connecting the inlet......................................................................................................48

5.2.3 Installation of the UVC clarifying unit............................................................................49

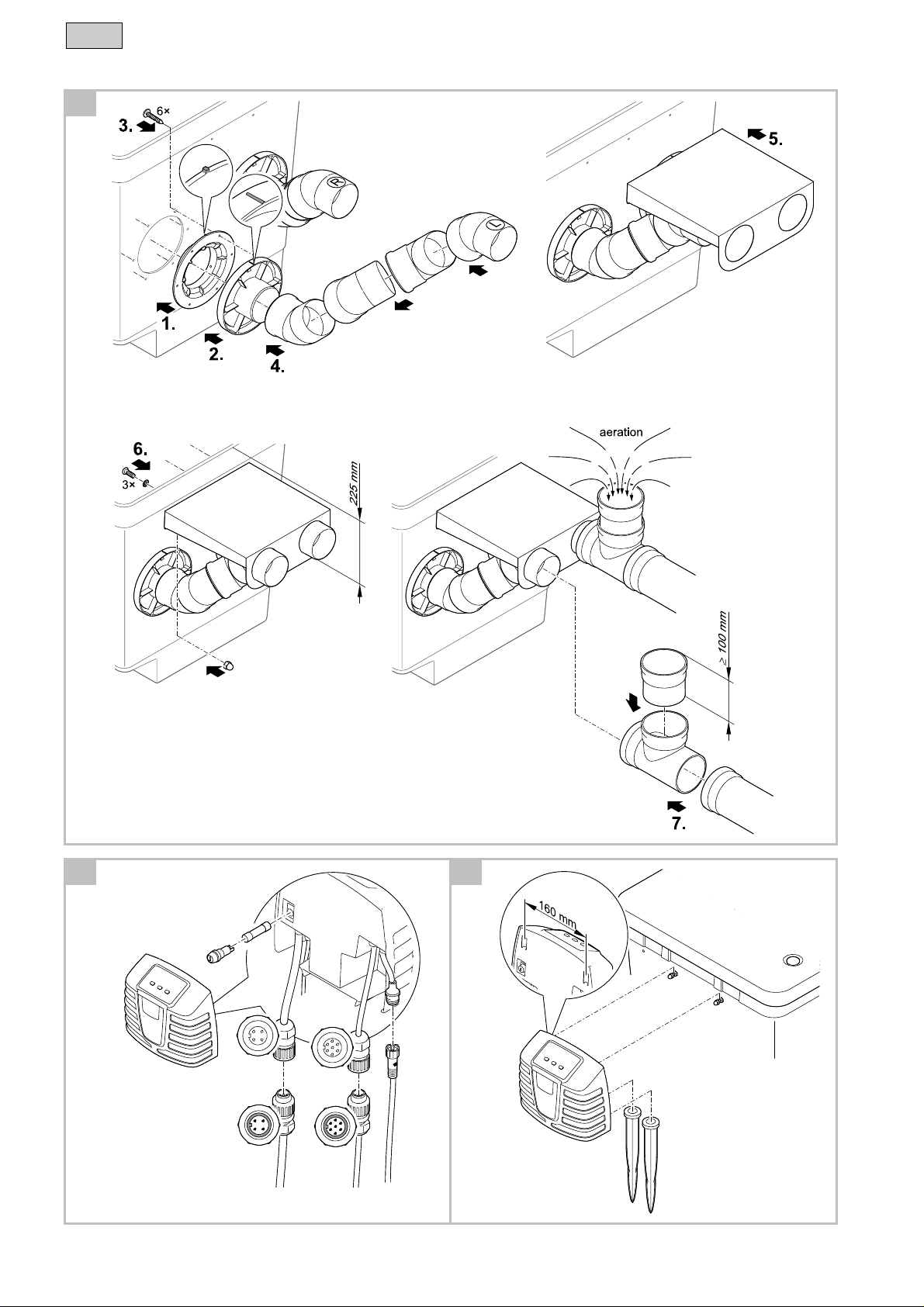

5.2.4 Connecting the dirt outlet..............................................................................................49

5.3 Individual operation of the drum filter module...........................................................................50

5.4 Connecting and installing the control system ...........................................................................51

6Commissioning/start-up ....................................................................................................................52

6.1 Order of starting up steps .........................................................................................................52

6.2 Adjusting the level detection device..........................................................................................54

7Operation...........................................................................................................................................55

7.1 Control system overview...........................................................................................................55

7.2 Switching ON/OFF....................................................................................................................55

7.3 Operating modes ......................................................................................................................56

7.4 Manual cleaning........................................................................................................................56

7.5 Settings in the menus ...............................................................................................................56

7.5.1 C

CL

L: Cleaning time "Cleaning".........................................................................................56

7.5.2 E

EC

C: Extended cleaning time "Extra Cleaning"................................................................57

7.5.3 I

In

n: Time-dependent cleaning "Interval")........................................................................57

7.6 Reading out the number of cleaning cycles..............................................................................58

7.6.1 Cleaning cycles in 24 hours..........................................................................................58

7.6.2 Total cleaning cycles ....................................................................................................58

7.7 Loading default settings............................................................................................................58

7.8 System messages.....................................................................................................................59

8Remedy of faults...............................................................................................................................63

- GB -