3 | EN

Screw-on cable tray systems

Table of contents

Table of contents

1 About these instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Target group ....................................................5

1.2 Relevance of these instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.3 Types of warning information ........................................5

1.4 Depiction conventions .............................................5

1.5 Basic standards and regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.6 Applicable documents .............................................6

2 Correct use ...............................................6

3 Safety ...................................................6

3.1 General safety information ..........................................6

3.2 Personal protective equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3.3 Personal tools ...................................................7

4 System overview ..........................................8

4.1 System description ...............................................8

4.1.1 Cable trays ............................................................ 8

4.1.2 Connectors ............................................................ 9

4.1.3 Fittings .............................................................. 10

4.1.4 Cover for cable trays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1.5 Cover for fittings ....................................................... 18

4.1.6 Accessories .......................................................... 19

5 Mounting ................................................20

5.1 Cutting the cable tray .............................................21

5.2 Mounting the joint plate ...........................................22

5.3 Applying the edge protection strip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

5.4 Connecting cable trays ...........................................23

5.4.1 Creating a straight connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.4.2 Creating an angled connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.4.3 Creating a vertical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.5 Mounting fittings ................................................35

5.5.1 Supporting a fitting ..................................................... 35

5.5.2 Mounting WKV angle connections on a fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

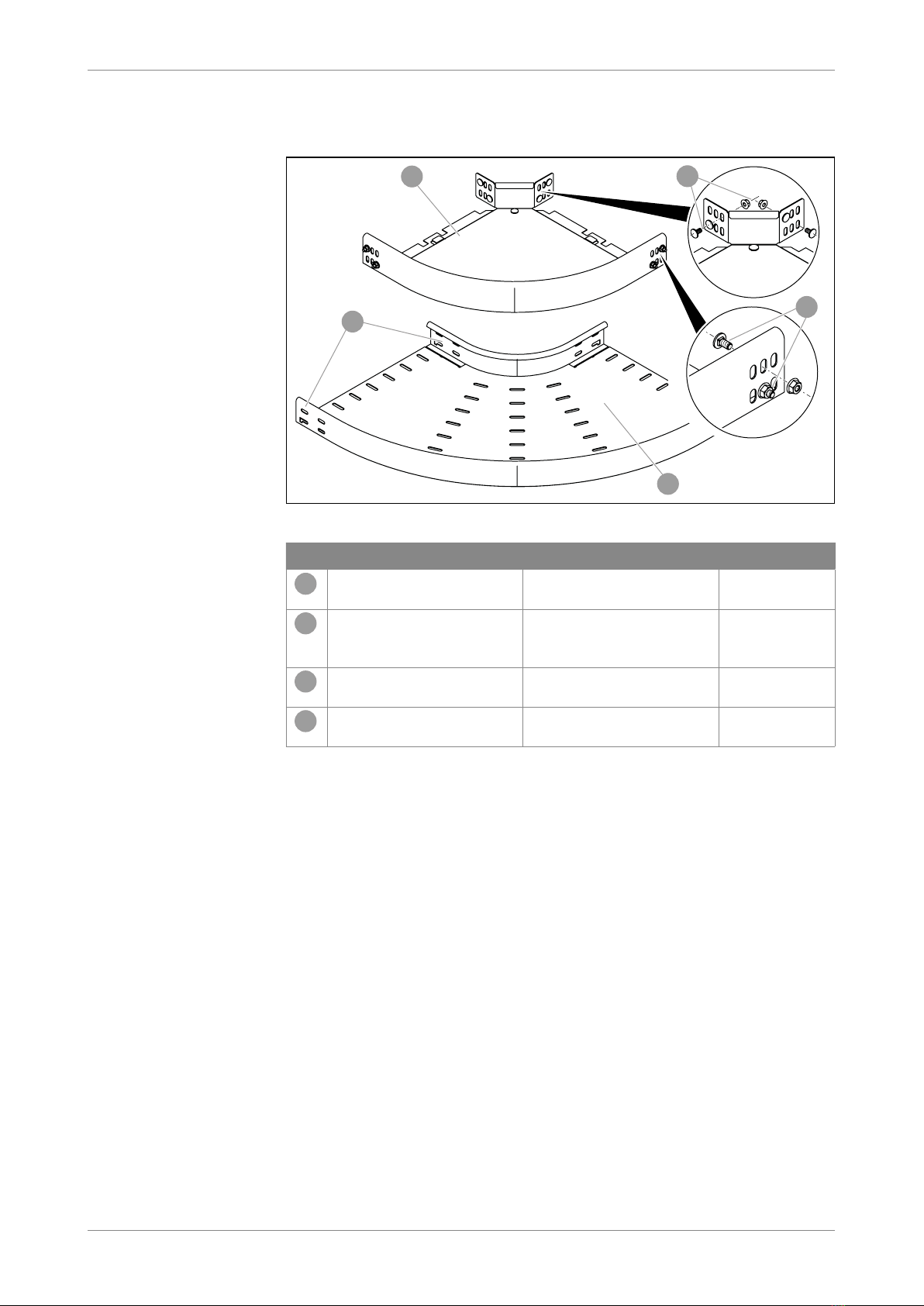

5.5.3 Mounting the 45°/90° bend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.5.4 Mounting a falling/rising vertical bend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.5.5 Mounting an add-on tee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.5.6 Mounting the T branch piece . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.5.7 Mounting a cross-over . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.5.8 Mounting adjustable bend elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.5.9 Mounting a reducer profile/end closure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.6 Mounting barrier strips ............................................56

5.7 Creating equipotential bonding .....................................56

5.8 Mounting the cover ..............................................57

5.8.1 Mounting the cover with cover clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.8.2 Mounting the cover with turn buckle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5.8.3 Mounting a fitting cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60