Table of Contents

Conditioning Instruction BIOM® 5 (G/55185/0818/en) ii / iii

Table of Contents

1 Applicability..................................................................................................................................1

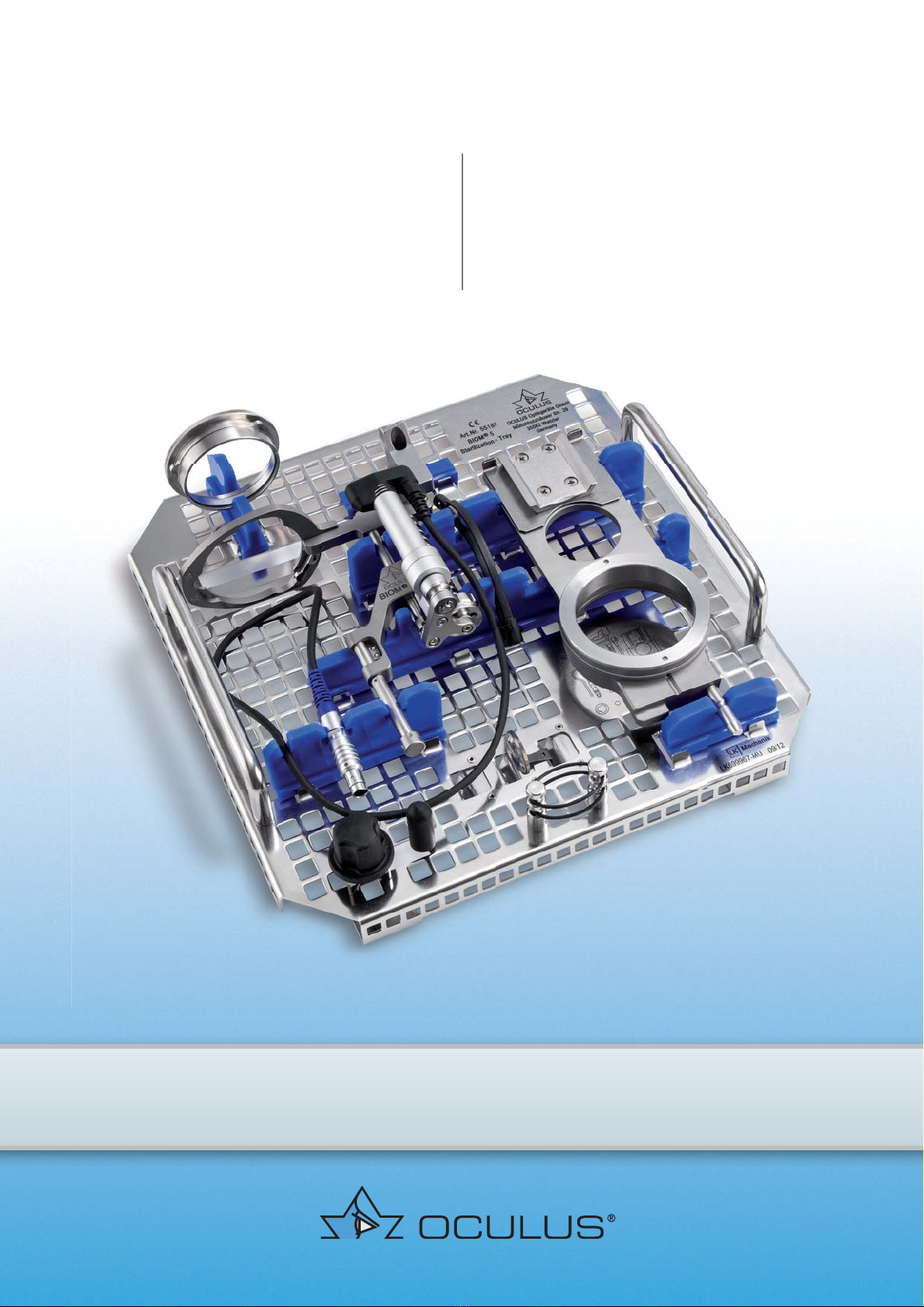

2 Safety Instructions......................................................................................................................1

2.1 About this Manual .........................................................................................................1

2.1.1 Used Graphic Symbols.................................................................................2

2.2 Safety Instructions for Use..........................................................................................2

3 Conditioning Procedure.............................................................................................................4

4 Components of the BIOM® 5 to be Conditioned ...............................................................5

5 Cleaning and Disinfection ........................................................................................................6

5.1 Preparation: Dismantle the BIOM® 5 .......................................................................6

5.2 Pre-Cleaning ....................................................................................................................8

5.3 Cleaning/Disinfection by Machine ............................................................................9

5.3.1 Information About Cleaning/Disinfection by Machine......................9

5.3.2 Cleaning and Disinfecting by Machine................................................ 10

5.4 Manual Cleaning/Disinfection ................................................................................. 13

5.5 Cleaning in an Ultrasonic Bath (Optional)........................................................... 14

6 Steam Sterilisation .................................................................................................................. 15

6.1 Prior to Steam Sterilisation ...................................................................................... 15

6.1.1 Function Check Prior to Steam Sterilisation...................................... 15

6.1.2 Lubrication................................................................................................... 18

6.1.3 Packaging..................................................................................................... 19

6.2 Steam Sterilisation...................................................................................................... 19

7 Storage........................................................................................................................................ 20

8 Disposal....................................................................................................................................... 20

9 Guarantee and Service............................................................................................................ 20

9.1 Manufacturer and Service Address ........................................................................ 21

10 Overview: Permitted Sterilisation Method – List of Articles ....................................... 22

11 Consumables and Sterilisable Accessories........................................................................ 25

12 Appendix..................................................................................................................................... 25