5

Operating Instructions and Parts Manual 24369

DIGITAL BATTERY

ANALYZER

• IF BATTERY ACID COMES INTO CONTACT WITH

SKIN OR THE CLOTHES, IMMEDIATELY WASH

WITH SOAP AND WATER. IF THE BATTERY ACID

GETS INTO EYES, RINSE EYES WITH WATER

RIGHT AWAY FOR AT LEAST 10 MINUTES THEN

GO TO THE HOSPITAL.

• This equipment is intended only for professional

use by personnel trained in performing the service

functions for which it is has been designed.

• This equipment is designed for servicing a variety

of vehicles in a safe, convenient manner. However,

differences in vehicle makes and models may make

it impossible to use this equipment as it is intended.

Do not attempt to force the use of this equipment

on an application for which it is not designed to

perform.

• The procedures documented in this manual are to

serve as guidelines for the use of this equipment.

• In addition to these guidelines, always follow the

manufacturer’s recommended procedures when

servicing each unique vehicle.

• The use of this equipment is simple and

straightforward if you follow the instructions. When

operating this equipment, use common sense, and

always stop to think before connecting the Battery

tester or performing any tests.

• Position cords to reduce risk of damage by hood,

door or moving engine parts.

• Stay clear of fan blades, belts, pulleys and other

moving parts that can cause injury to persons.

• Check polarity of battery posts.

THESE TEST PROCEDURES ARE FOR

NEGATIVE GROUNDED VEHICLES ONLY. FOR

POSITIVE GROUNDED VEHICLES, SEE VEHICLE

MANUFACTURER REPAIR MANUAL.

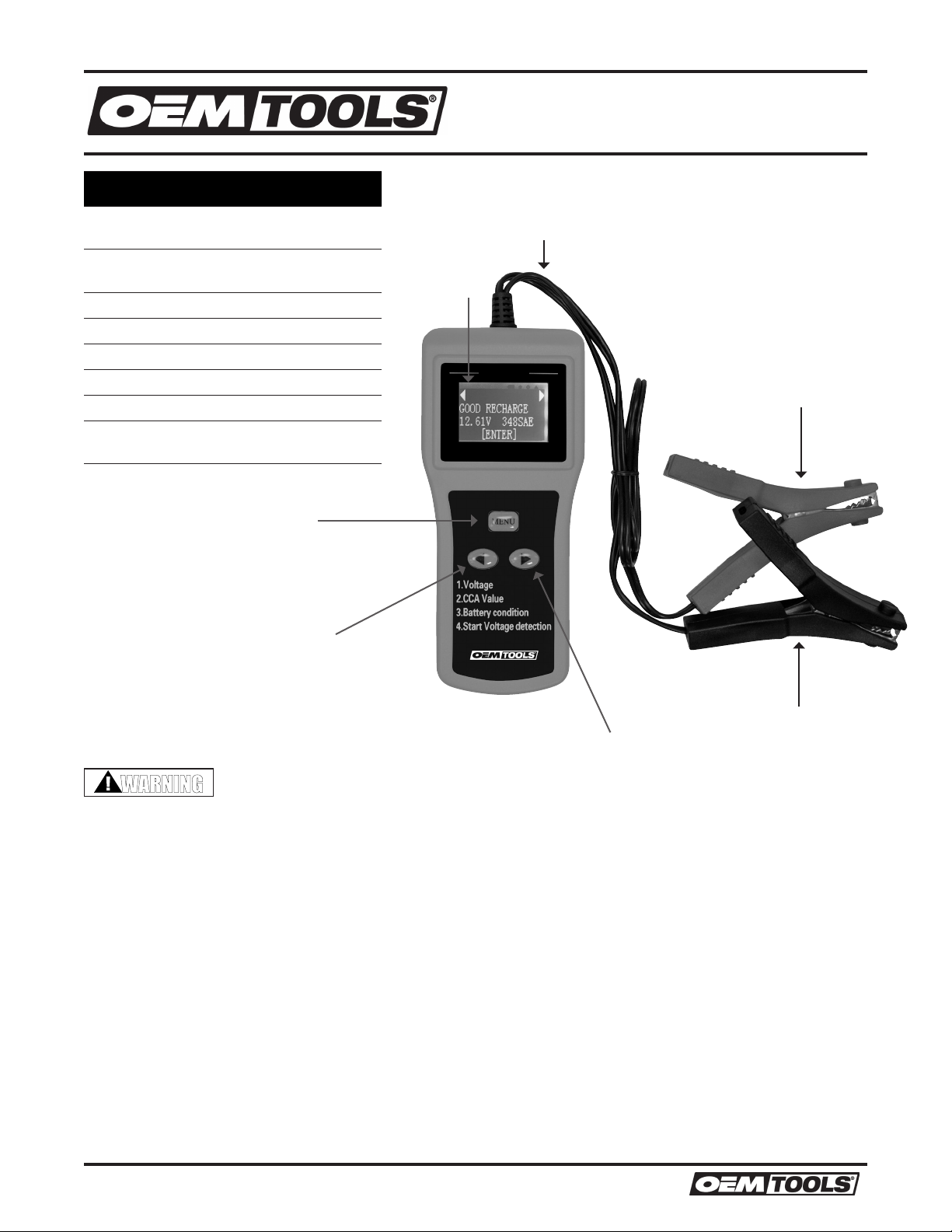

BATTERY TEST

1. Before you test a battery in a vehicle, turn off the

ignition, all accessories and loads.

2. Close all the vehicle doors and the trunk lid.

3. Determine which post of the battery is grounded

(connected) to the chassis.

4. Connect NEGATIVE (black) clip to vehicle chassis

or engine block away from the battery.

5. Connect POSITIVE (red) clip from battery tester to

POSITIVE (POS, P, +) ungrounded post of battery.

6. Do not connect clip to carburetor, fuel lines, or

sheet metal body parts. Connect to a heavy gauge

metal part of the frame or engine block.

Note: When disconnecting, remove clip from

vehicle chassis FIRST, then remove the clip from

the battery terminal.

7. Make sure you have put a 9V internal battery into

the tester’s battery chamber. If the LCD screen

shows “POWER LOW”, then the internal 9V battery

needs to be replaced . Replace it before starting

test. Note that nothing will be seen on the screen

until the tester is connected to a vehicle battery.

8. Press the “tu” button to select Battery Test. The

screen will show “BATTERY TYPE” selection.

Press the “t u” button to select the battery type:

REGULAR LIQUID, AGM BATTERY or VRLA/GEL

BATTERY.

9. Press “Enter” button to confirm choice.

10. The screen will show “RATING STANDARD”. Press

the “t u” button to select the battery standard:

SAE、DIN、IEC、EN or CA (MCA)

SAE: United States Standard

EN: European Standard

DIN: German Standard

IEC: International Electrical Science and

Technology Association

CA (MCA): Normal starting current or maritime

starting current

11. Press the “Enter” button to confirm the choice and

go to next step.

12. The screen will show “RATING CAPACITY”. Press

the “t u” button to select the battery capacity of

CCA. With each press of the button, the value will

increase or decrease 5 units.

13. This tester’s testing range:

SAE:、40 ~ 2,000 CCA

EN: 40 ~ 2,100 CCA

DIN:、25 ~ 1,300 CCA

IEC:、30 ~ 1,500 CCA

CA (MCA): 240 ~ 1,440 CA (MCA)

14. Press the “Enter” button to confirm the input value

of the battery capacity and begin the test.

15. The screen will show “TESTING”. Testing is in

progress. The test result will show up after 2

seconds.

16. If the tester asks “BATTERY CHARGED?”, press

the “t u” button to select “YES” or “NO”. Press

“Enter” button to confim choice and proceed to

the next step.

Note: The Tester will judge the battery status and

decide whether to show this Step or not, it doesn’t

appear every time.

05/15

2015 ©OEMTOOLS