TUF-2000F User Manual

8

display is used as the display device.

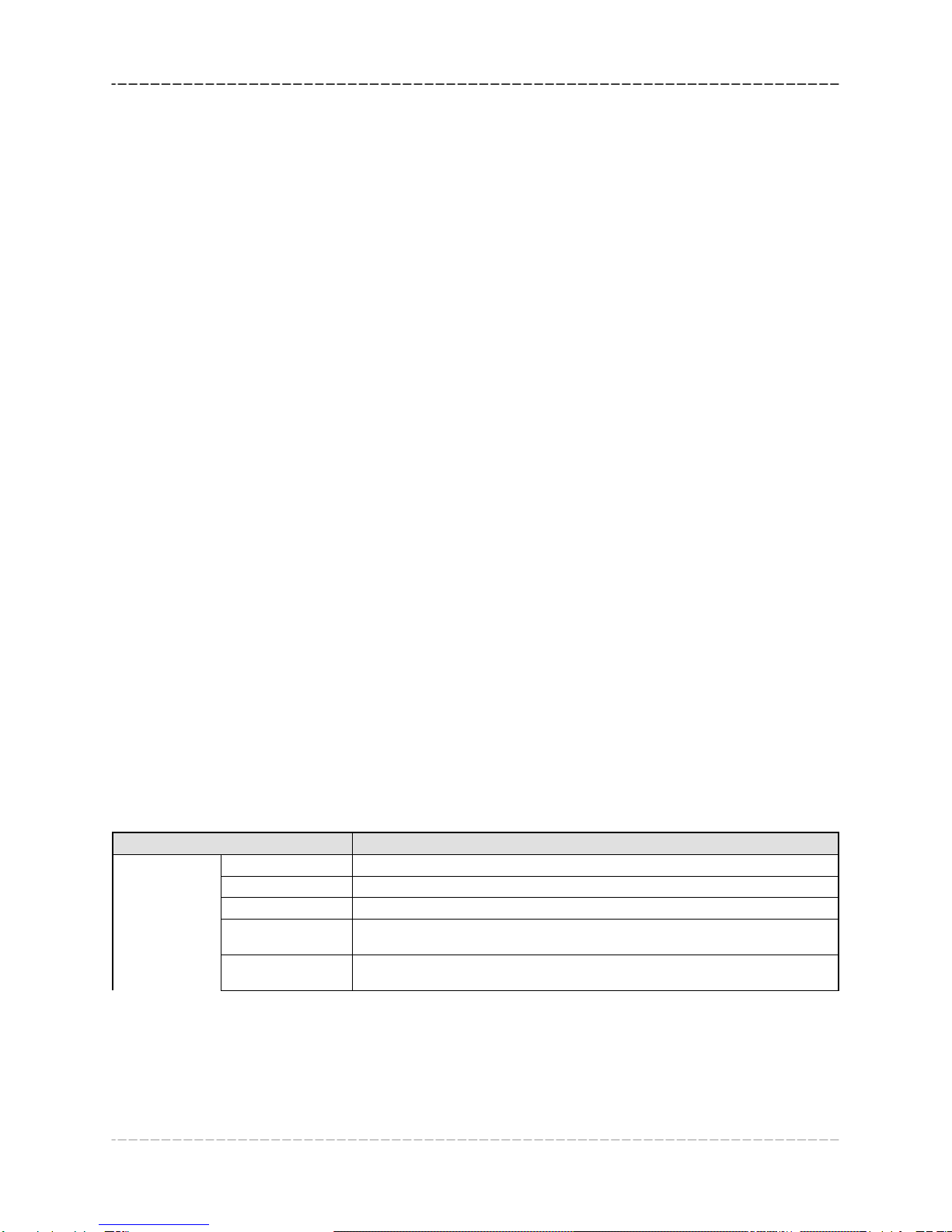

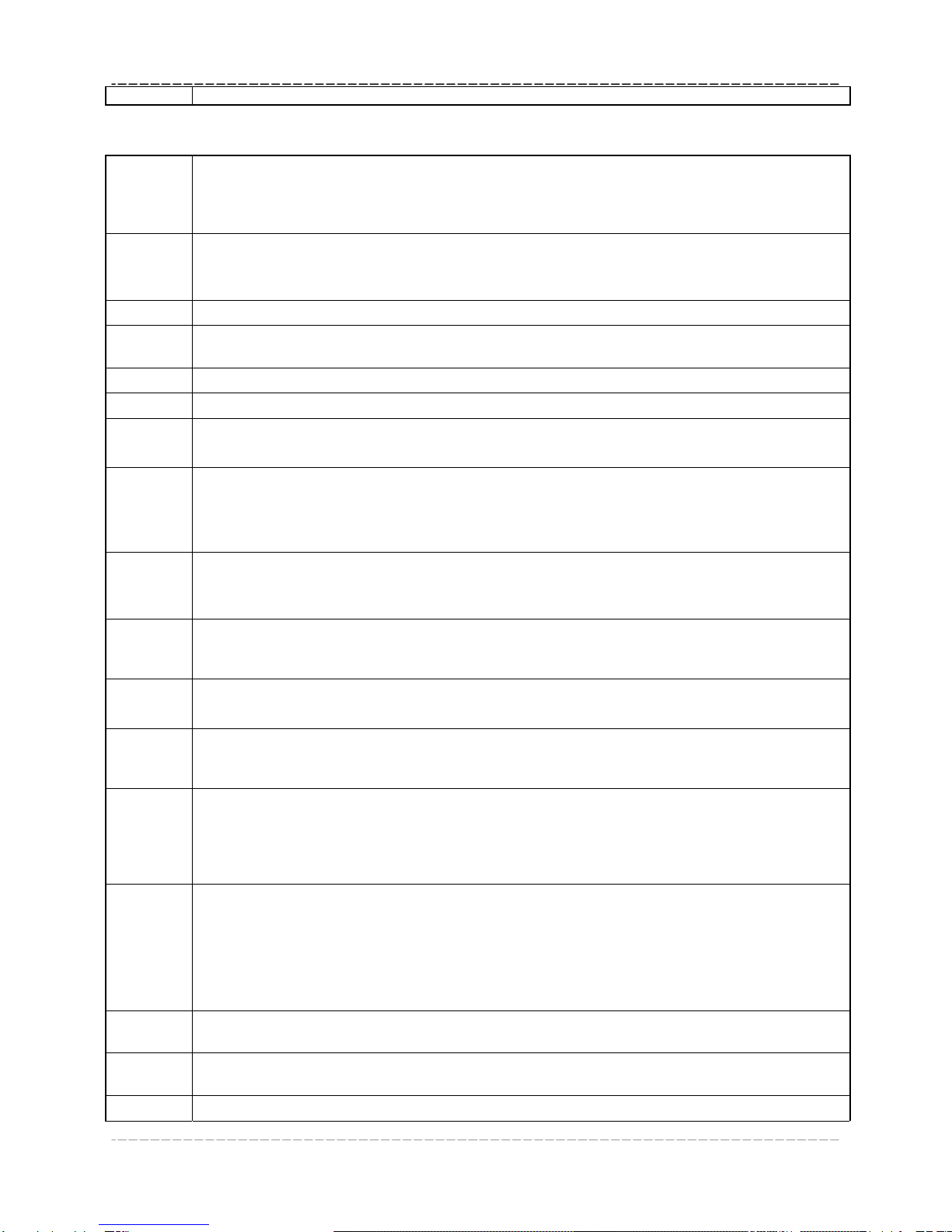

M3.

Setup for local segmental LCD display. Enter 0 or 1 for the non-auto-scan mode;

Enter 2~39 for the auto-scan mode. In the auto-scan mode the display will

automatically scan displaying from 00 to the entered number of the local segmental

LCD display.

M40

Flow rate damper for a stable value. The damping parameter ranges form 0 to 999

seconds.

0 means there is no damping. Factory default is 10 seconds

M41 Low flow rate (or zero flow rate) cut-off to avoid invalid accumulation.

M42 Zero calibration/Zero point setup. Make sure the liquid in the pipe is not running

while doing the setup.

M43 Clear the zero point value, and restore the solidified zero point value.

M44 Set up a flow bias. Generally this value should be 0.

M45 Flow rate scale factor. The default value is ‘1’.

Keep this value as ‘1’, when no calibration has been made.

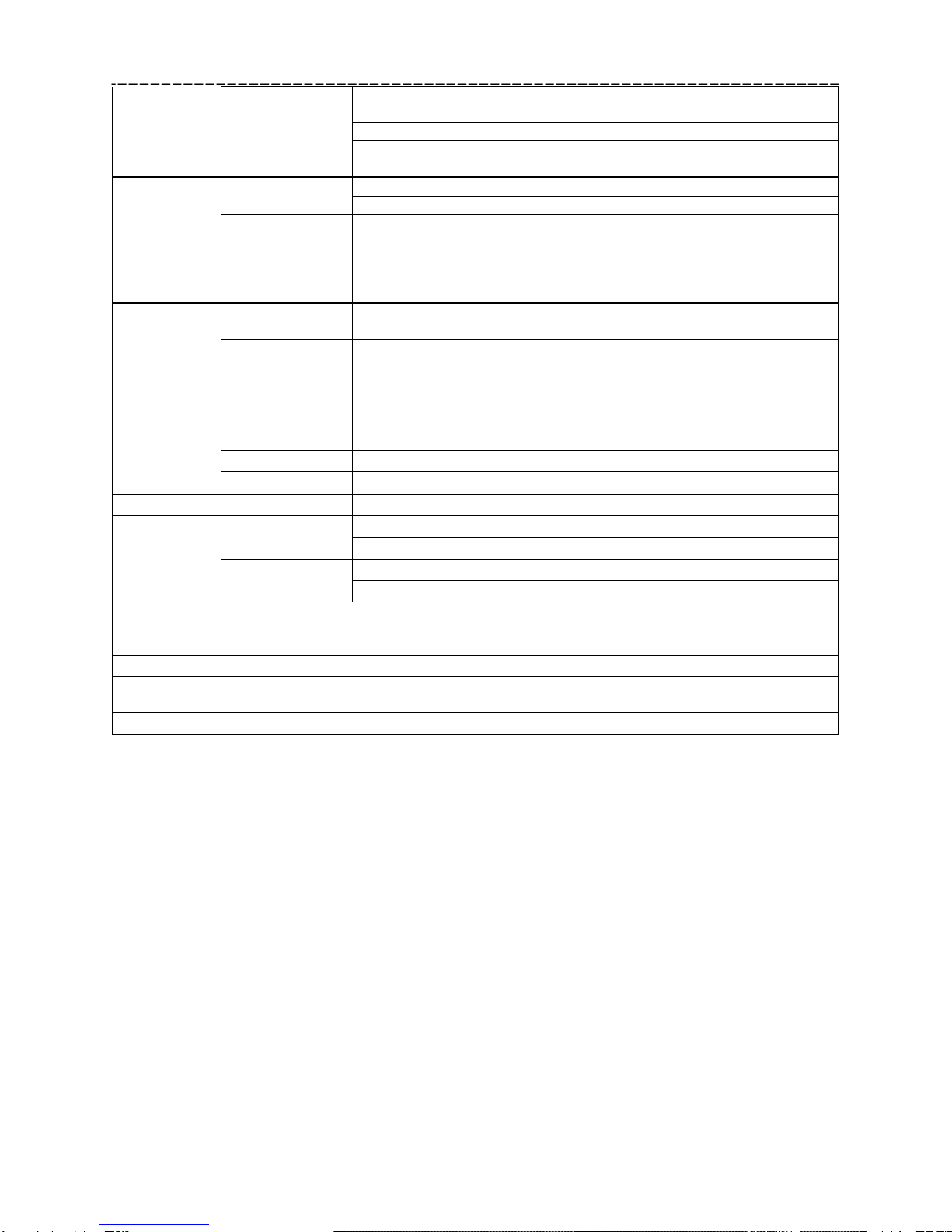

M46

Networks address identification number. Any integer can be entered except

13(0DH, carriage return), 10 (0AH, line feeding), 42 (2AH), 38, 65535.

Every set of the instrument in a network environment should have a unique IDN.

Please refer to the chapter for communication.

M47

System locker to avoid modification of the system parameters.

If password is forgotten, you could send a command ‘LOCK0’ to the serial input to

unlock. Or you can write 0 to REGISTER49-50 under MODBUS protocol.

M48

Entry to linearity correcting data inputs. By using of this function, the non-linearity of

flow meter will be corrected. Correcting data shall be obtained by careful

calibration.

M49 Displays the input contents for the serial port.

By checking the displays, you can know if the communication is ok.

M50

Switches for the built-in data logger. There are as many as 22 different items can

be chosen. To turn this function, select ‘YES’ the system will ask for selecting the

items. There are 22 items available. Turn on all those items you want to output

M51

Window to setup the time of scheduled output function (data logger, or

Thermo-printer). This includes start time, time interval and how many times of

output. When a number great than 8000 entered for the times of output, It means

the output will be keeping always. The minimum time interval is 1 second and the

maximum is 24 hours.

M52

Data logging direction control.

(1) If ‘Send to RS485’ is selected, all the data produced by the data logger will be

transmitted out through the RS-232/RS485 interface

(2) If ‘To the internal serial BUS is selected, the data will be transmitted to the

internal serial bus which allows a thermal printer, or a 4-20mA analog output

module, to be connected to it.

M53 Display analog inputs, AI5, current value and its corresponding temperature or

pressure or liquid level value.

M54 Pulse width setup for the OCT (OCT1) output. Minimum is 6 mS, maximum is 1000

mS

M55 Select analog output (4-20mA current loop, or CL) mode. Available options: