OPM223/253

3

Table of contents

1 Safety instructions . . . . . . . . . . . . .4

1.1 Designated use . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Installation, commissioning and operation . . 4

1.3 Operational safety . . . . . . . . . . . . . . . . . . . . 4

1.4 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.5 Notes on safety icons and symbols . . . . . . . 5

2 Identification . . . . . . . . . . . . . . . . . .6

2.1 Device designation . . . . . . . . . . . . . . . . . . . 6

2.2 Scope of delivery . . . . . . . . . . . . . . . . . . . . . 7

2.3 Certificates and approvals . . . . . . . . . . . . . . 7

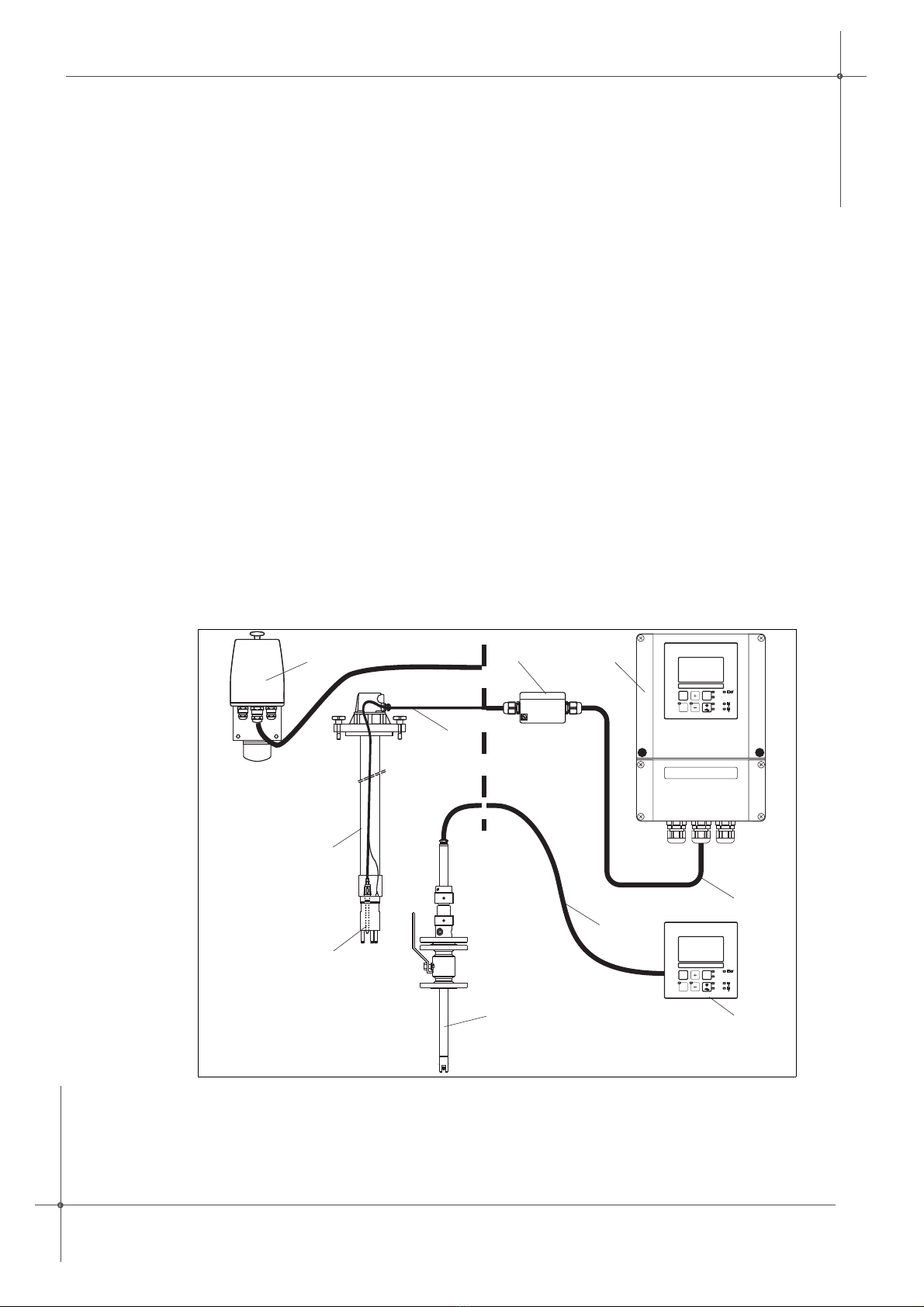

3 Installation . . . . . . . . . . . . . . . . . . . .8

3.1 Quick installation guide . . . . . . . . . . . . . . . . 8

3.2 Incoming acceptance, transport, storage . . . 9

3.3 Installation conditions . . . . . . . . . . . . . . . . . 9

3.4 Installation instructions . . . . . . . . . . . . . . . 11

3.5 Post-installation check . . . . . . . . . . . . . . . . 14

4 Wiring . . . . . . . . . . . . . . . . . . . . . . .15

4.1 Electrical connection . . . . . . . . . . . . . . . . . 16

4.2 Alarm contact . . . . . . . . . . . . . . . . . . . . . . . 22

4.3 Post-connection check . . . . . . . . . . . . . . . . 22

5 Operation . . . . . . . . . . . . . . . . . . . .23

5.1 Quick operation guide . . . . . . . . . . . . . . . . 23

5.2 Display and operating elements . . . . . . . . 23

5.3 Local Operation . . . . . . . . . . . . . . . . . . . . . 27

5.4 System configuration . . . . . . . . . . . . . . . . . 30

5.5 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . 59

6 Commissioning . . . . . . . . . . . . . . .65

6.1 Things to note when commissioning

ISFET sensors . . . . . . . . . . . . . . . . . . . . . . 65

6.2 Function check . . . . . . . . . . . . . . . . . . . . . . 65

6.3 Switching on . . . . . . . . . . . . . . . . . . . . . . . 65

6.4 Quick start-up . . . . . . . . . . . . . . . . . . . . . . 67

7 Maintenance. . . . . . . . . . . . . . . . . .69

7.1 Maintenance transmitter . . . . . . . . . . . . . . 69

7.2 Maintenance of the entire measuring point 71

7.3 "Optoscope" service tool . . . . . . . . . . . . . . 73

8 Accessories. . . . . . . . . . . . . . . . . . 74

8.1 Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . 74

8.2 Connection accessories . . . . . . . . . . . . . . 74

8.3 Mounting accessories . . . . . . . . . . . . . . . . 75

8.4 Assemblies . . . . . . . . . . . . . . . . . . . . . . . . 76

8.5 Software and hardware add-ons . . . . . . . 77

8.6 Calibration solutions . . . . . . . . . . . . . . . . . 77

8.7 Optoscope . . . . . . . . . . . . . . . . . . . . . . . . 77

9 Trouble-shooting. . . . . . . . . . . . . . 78

9.1 Trouble-shooting instructions . . . . . . . . . . 78

9.2 System error messages . . . . . . . . . . . . . . 78

9.3 Process specific errors . . . . . . . . . . . . . . . 81

9.4 Instrument specific errors . . . . . . . . . . . . . 84

9.5 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . 86

9.6 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

9.7 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . 91

10 Technical data . . . . . . . . . . . . . . . . 92

10.1 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

10.2 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

10.3 Power supply . . . . . . . . . . . . . . . . . . . . . . 93

10.4 Environment . . . . . . . . . . . . . . . . . . . . . . . 93

10.5 Performance characteristics . . . . . . . . . . . 94

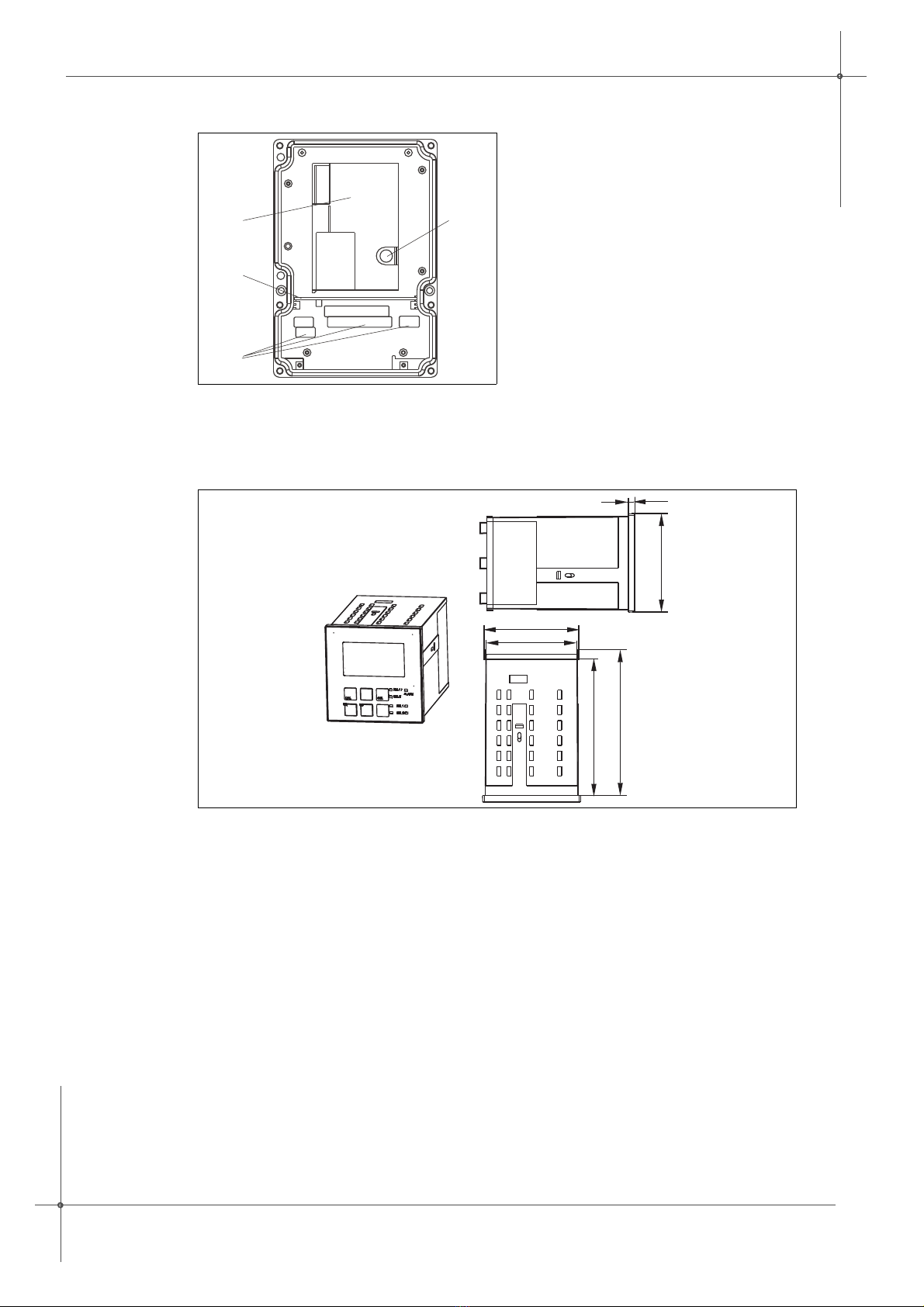

10.6 Mechanical construction . . . . . . . . . . . . . . 94

11 Appendix . . . . . . . . . . . . . . . . . . . . 96

Index. . . . . . . . . . . . . . . . . . . . . . . 101