4

Planetary Final Drive Service Manual

Introduction

This manual is a step-by-step guide to the disassembly and

assembly of the S40B SeriesTorque-Hub®units with ratios of XX:X

or lower. It is designed for the customer or mechanic who is

repairing this particular Torque-Hub® model.

Users of this manual should note that each part mentioned is

followed by an identification number enclosed in parentheses.

These part numbers may be referred to in the Parts List and

Assembly Drawing sections of this manual.

Specialized tools used to assemble this unit are noted in the

assembly procedures and diagrammed in the Assembly Tools

section.

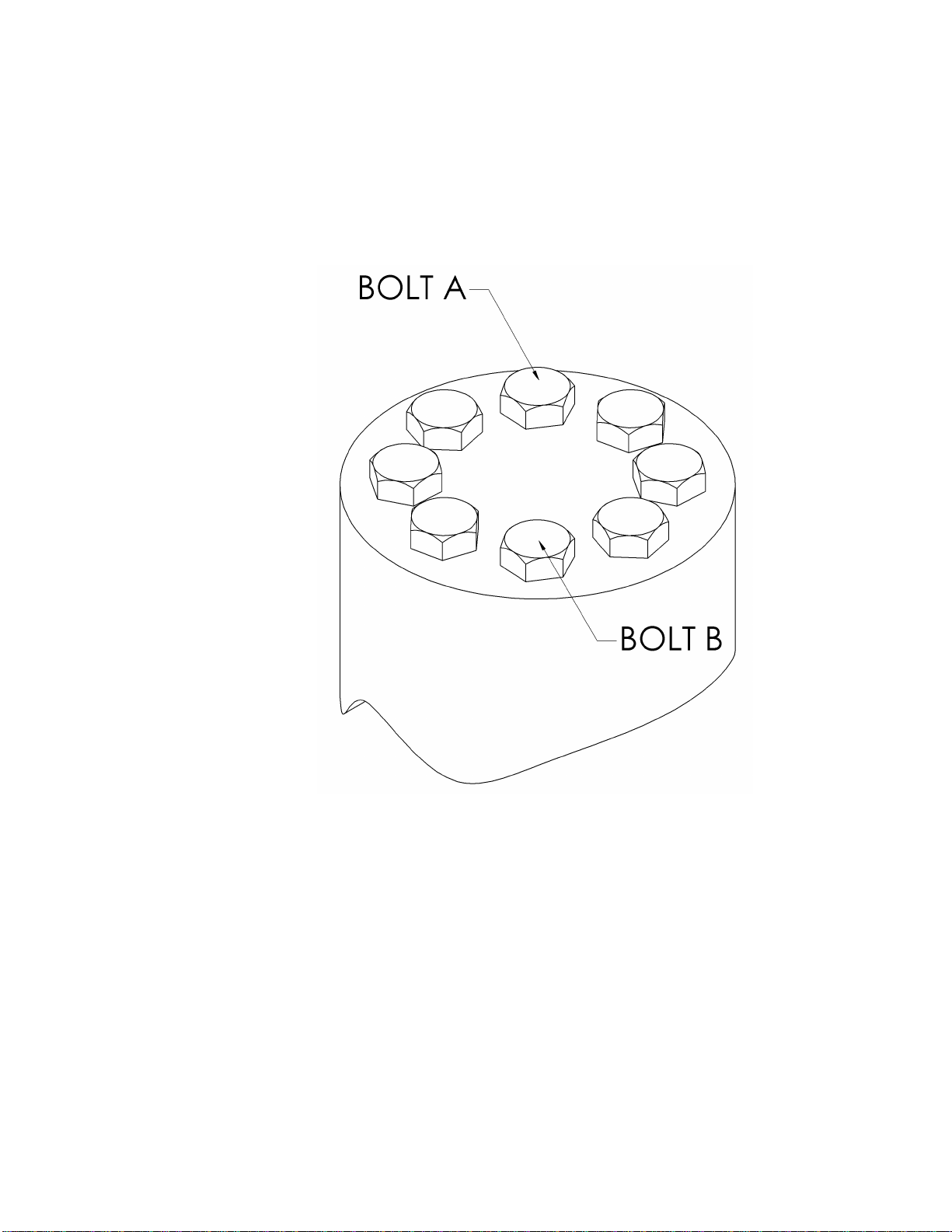

Users should familiarize themselves with the procedures for roll and

leak testing, as well as bolt tightening and torquing found on the

following three pages before starting any repairs.

Standard safety practices should be followed during the

disassembly and assembly procedures described. Safety glasses

and safety shoes should be worn, and heavy, heat resistant gloves

should be used when handling heated components. Be especially

alert when you see the word CAUTION. This indicates that a

particular operation could cause personal injury if not performed

properly or if certain safety procedures are not followed. The word

NOTE is used to bring attention to certain procedures or helpful

hints that will aid in the disassembly and assembly process.