5. Start-up/Shut-down

Before Start-up

Read operation manual before start-up and follow instructions.

Upon start-up of the high pressure cleaner indoors, proper ventilation

and exhaust evacuation to be guaranteed. Official safety regulations to

be followed.

In order to guarantee proper condition of the machine and trouble-free

operation, carry out the following checks before start-up:

•General condition of the unit (connections, seals, etc.)

•Power cables/connections

•Check all hoses for damage

•Air supply to be guaranteed

•Fill in all consumables required

•Check correct oil level of high pressure pump (dip stick), only oil qualities

approved by OERTZEN to be used (OERTZEN OSP special pump oil).

•Check high pressure pump/pump connections for leaks

•Machine only to be run with absolutely clean water. Thoroughly flush water

supply hose before connection. Depending on water quality, filter to be

checked in regular short intervals and replaced whenever needed.

•Machine to be run horizontally (+/- 5°)

In order to guarantee proper condition of the machine and trouble-free

operation, carry out the following checks during operation:

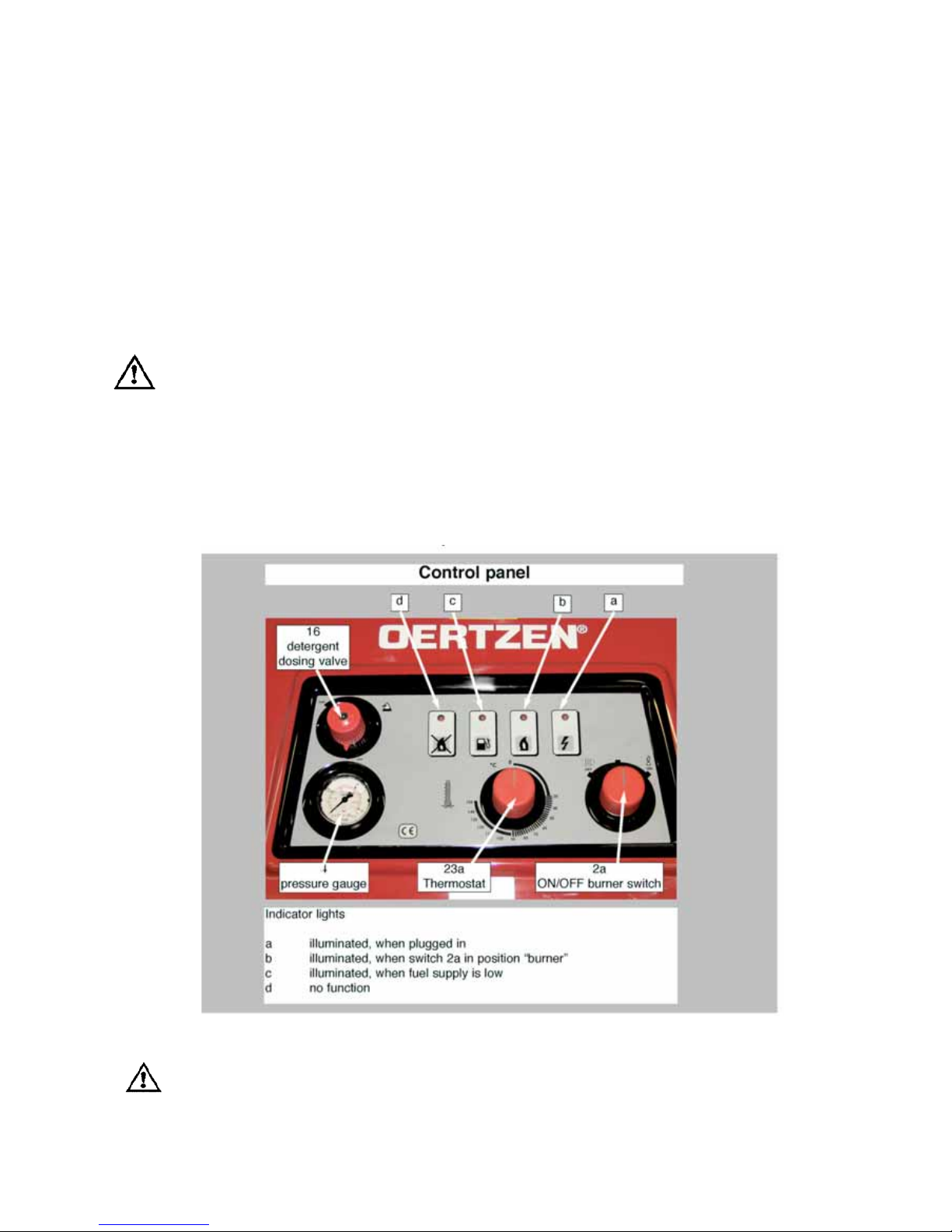

•Observe control indications/devices whether functioning

•Observe pressure whether varying

•Observe high pressure pump, hoses, connections whether leaking

•Observe unnormal noise

In case of malfunctions switch off machine immediately, eliminate cause

according to chapter "Trouble Shooting", call qualified service.

Connections

Water Connection

Water inlet (6) of the unit to be connected to the water distribution network by

means of an internally clean, min. ” water hose (diameter: see table below).

For connections to the potable water distribution network DIN 1988 to be

considered (for short-time connection a back-flow preventer with non-return

protection and ventilation to be used).

Flow Pressure Flow Rate minimum *

minimum: 2 bar

maximum: 8 bar 15 l/min. " supply hose

21 l/min. 1" supply hose

30 l/min. 1 " supply hose

* see Technical Data

Water shortage may cause severe damages on the pump unit

(cavitation).