Page 10 Hotsy 5645 • 97-6580 • Rev. 8/03

2. Wash from the bottom to the top, using side-to-side

motions.This washes away heavy dirt and allows the

detergent to soak as you work toward the top.

3. Do not wash at a 90° angle to the work (straight at it).

This will allow water to splash back at you and

reduces your cleaning power. Wash at a 30° to 60°

angle to the work. This will allow the water to splash

away from you and the water will wash the dirt away

faster and easier.

4. Use the full width of the spray pattern to wash in a

wide path. Overlap spray paths for complete cover-

age. Wash from side to side, using slow, steady

motions.

5. The nozzle should be 12" to 24" from work, closer for

tough areas. Be careful on painted or delicate sur-

faces, the pressure may damage surface if the nozzle

is to close.

6. Small parts should be washed in a basket so the pres-

sure does not push them away. Larger, lightweight

parts should be clamped down so the pressure does

not push them away.

7. To rinse, turn the detergent metering valve clockwise

to stop the detergent flow through the valve. Always

rinse with cold water after using detergent. Rinse from

the top to the bottom to prevent the detergent from

dripping onto a rinsed area. For the best results, con-

tact your Hotsy dealer to help you select the best

detergent for your application.

To Stop

1. If detergents were used, draw clear water through the

system to purge detergent.

2. If burner was used, turn OFF burner switch, and

allow pump to run cold water through coil.

3. Move throttle control to idle position.

4. Turn key on engine counterclockwise (CCW) to OFF

position.

5. Turn OFF fuel shut-off valve.

6. Turn OFF water supply.

7. Squeeze trigger gun open to relieve system pressure.

STORAGE

DANGER: Do not store flammable liquids (gasoline,

solvents, etc.) near pressure washer, or in non-venti-

lated areas.

Protect from freezing by storing in a heated area, or by

flushing the system with antifreeze. To flush the system,

fill the float tank with antifreeze and remove spray nozzle

from wand. Start the machine and allow it to run until

antifreeze flows from the end of the wand. Place end of

wand into float tank and circulate the antifreeze through

system for several minutes. Open and close the trigger

gun several times to circulate antifreeze through the

unloader valve. Place detergent line into the float tank.

Open the detergent metering valve to draw antifreeze into

the detergent system.

If the pressure washer is not to be used for a considerable

length of time, it is recommended to flush the system

with antifreeze for rust protection.

MAINTENANCE

WARNING: Unauthorized machine modification or use

of non-approved replacement parts may cause per-

sonal injury and/or property damage and will void the

manufacturer warranty.

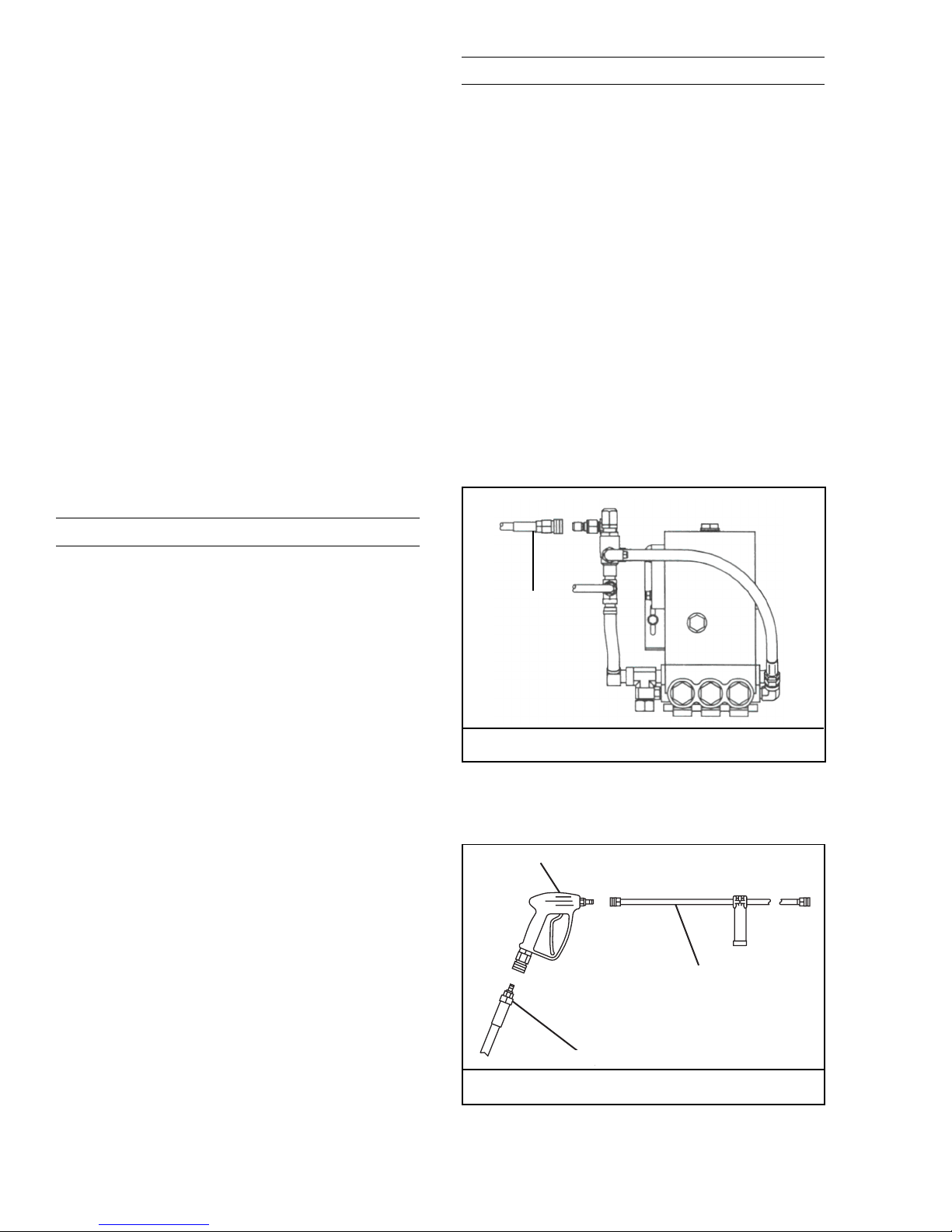

Pump

Use HOTSY Pump Oil (P/N 315068) or equivalent 30W

non-detergent oil for pump crankcase. Crankcase must

be filled to the full mark on the dipstick or to center of

sight glass window found on the rear of the pump. During

the break-in period, make sure the oil is changed after

the first 25 hours of operation. After that, replace oil every

3 months or 300 hours, whichever comes first.

DO NOT:

1. Pump acids.

2. Fail to winterize in freezing temperatures.

3. Allow pump to run dry.

4. Allow machine to run with trigger gun closed for more

than 3 minutes at any one time or damage to pump

may occur.

DO:

1. Use a water softener on the water system if known to

be high in mineral content.

2. Use only high quality detergents and follow manu-

facturer’s mix recommendations.

3. Immediately after using detergent solutions the sys-

tem should be flushed thoroughly with clear water.

4. Clean strainer screen on detergent line periodically.

Hour Meter

An optional hour meter (P/N 783865) is available for use

on the Model 5645. The hour meter will monitor the total

hours of operation of the pressure washer to signal when

routine maintenance is required.

Unloader Valve

WARNING: The unloader valve on this pressure

washer has been factory set and sealed and is a field

nonadjustable part. Tampering with the factory set-

ting may cause personal injury and/or property dam-

age, and will void the manufacturer warranty.

Relief Valve

WARNING: The relief valve on this pressure washer

has been factory set and sealed and is a field nonad-

justable part.Tampering with the factory setting may

cause personal injury and/or property damage, and

will void the manufacturer warranty.

Burner Fuel Filter

Drain water that has accumulated in fuel filter and clean

filter element as needed.