OFFICINE OROBICHE

S.p.A.

1/4

INSTRUCTION MANUAL FOR LEVEL SWITCHES

SERIES 20 Electric

24010 Ponteranica (Bergamo) ITALY

-

via Serena, 10

-

Tel. 0039/035/4530211

-

Fax 0039/035/570546

-

www.officineorobiche.it

-e-

******************************************************************************************************************************************************************

JULY ’0

5

Information subject to changes without prior notice

IST/099

-I

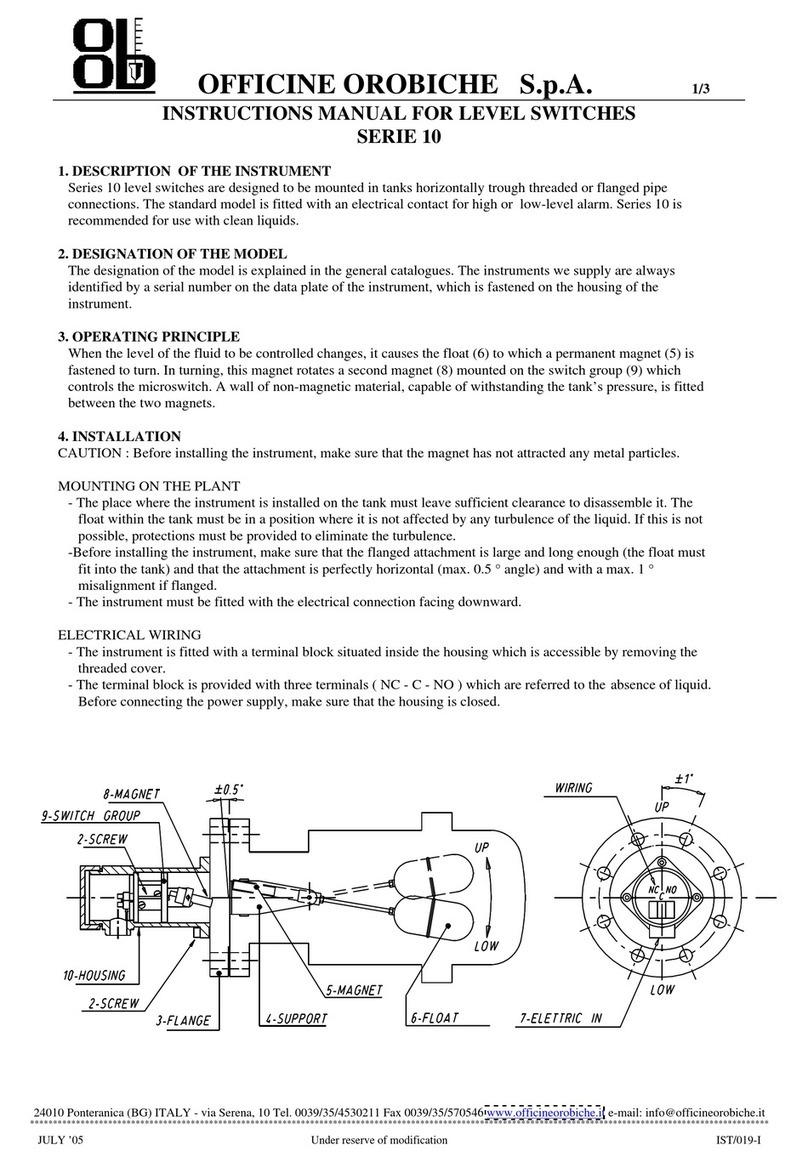

1. DESCRIPTION OF THE ITEM

Level switches model 20 have been conceived on the basis of lever principle and designed to be assembled on the side of

pressure containers.

Connections can be both threaded and flanged.

Operation rod starting succeeds by means of hydrostatic power and force of gravity; both operate in the same direction

and the opposite way. Their resultant makes the float (2) placed on the end of the lever arm (3) inside the pressure

recipient translate upright. The other lever arm end (3) is

fully inside the item body and controls one or two electric switch

groups placed inside the external sheath (6) by means of a connection rod moving system and a magnet starting. The

external sheath (6) can be water

-

tight or deflagration

-

tight.

2. MODEL D

EFINITION

Model definition is available in all our general catalogues.

All the items we supply are always to be identified by means of a serial number placed on the item identification plate.

Such plate is firmly secured on the item head.

3. FUNCTIONING P

RINCIPLE

The agency of hydrostatic power is a function both of the float volume and of the fluid specific mass and also and of the

level value. It can fluctuate from zero [float (2) completely uncovered] up to a maximal value [float (2) completely

dipped].

The latter value must be bigger than the one due to the system weight in order to grant the functioning even in the

presence of friction and attractive / repulsive magnetic forces. The resultant force represents the item margin.

Every item is distinguis

hed by two margins.

1-

gradient margin (hydrostatic power

-

force of gravity);

2-

descent margin (force of gravity).

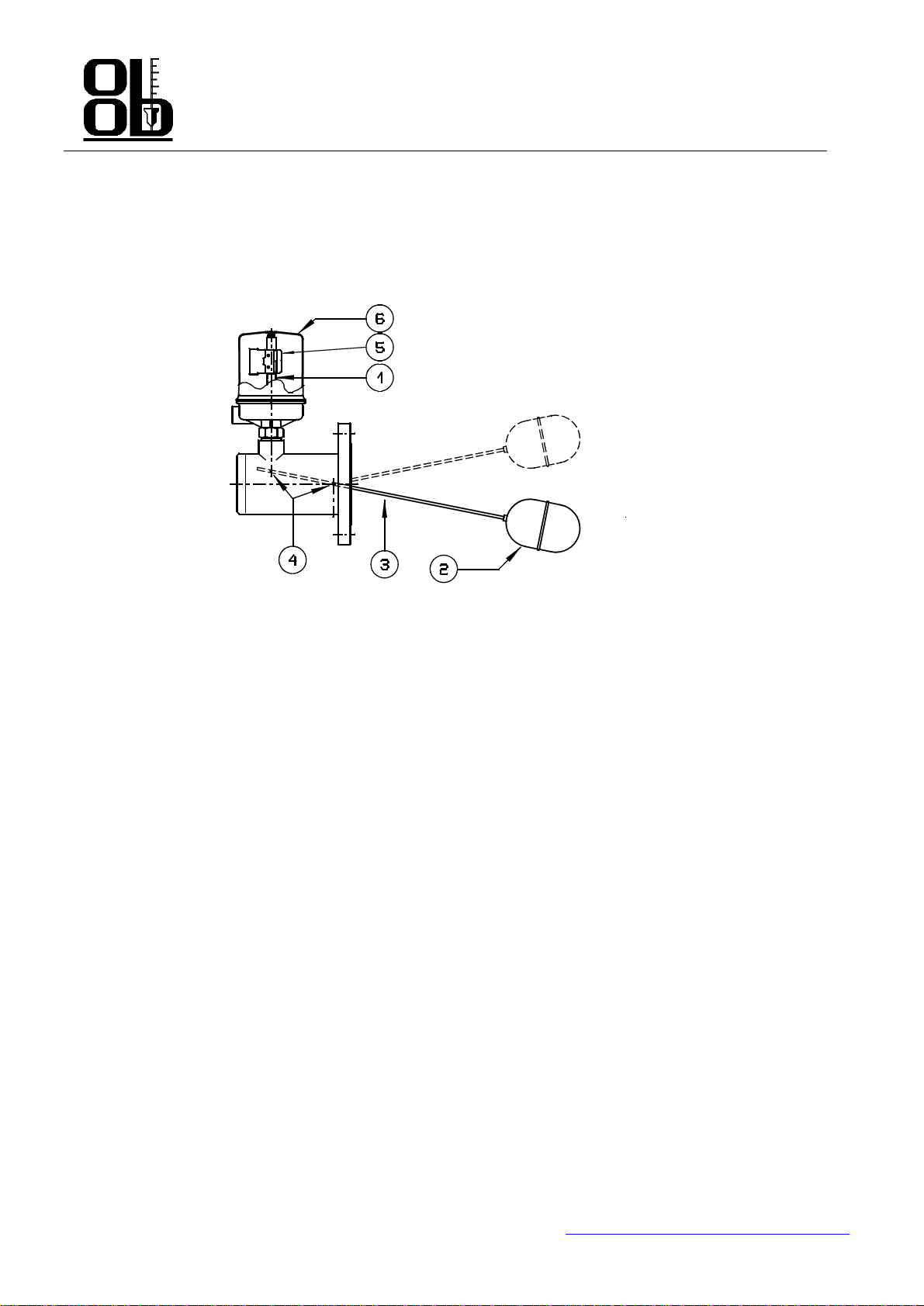

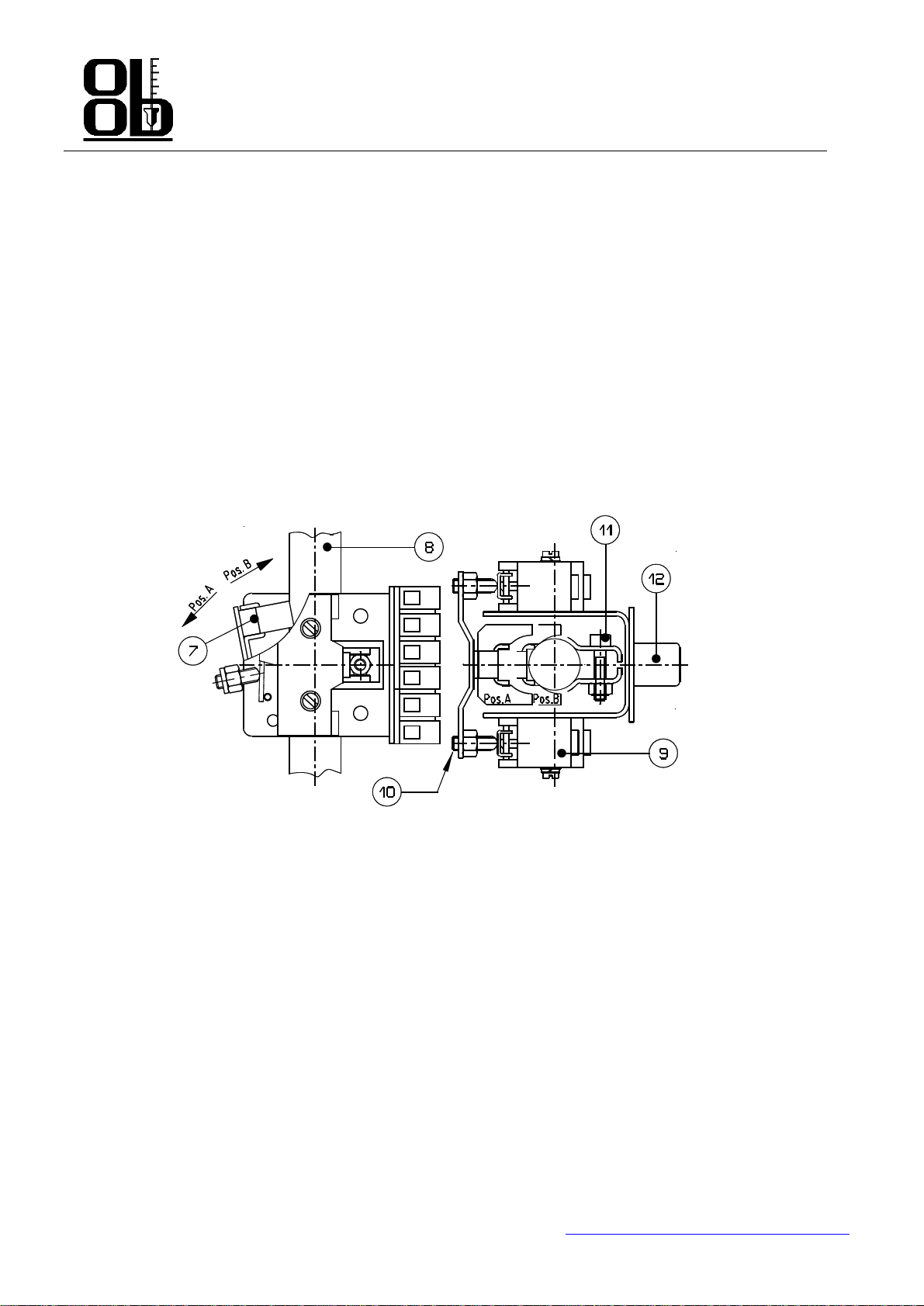

A connecting rod is secured on the operating lever arm opposite to the float (2) end bearing on the top a “magnetic

anchor” (1). Such anc

hor (1) can only move upright inside a “sump” made of anti

-

magnetic material (stainless steel). The

sump head is closed and separates the item section under process pressure from the section under atmospheric pressure.

Thickness is calculated according to

ASME VIII div. 1. No stuffing box nor mechanical seal exist. When the anchor (1)

rises or lowers, it reaches a magnet (7) field outside the sump, mechanically connected to one or two electric

microswitches.

The magnet, together with the microswitches, for

m the “switch group” also called “release unit (5)”.

Maximum two release units can be assembled on every item; functioning takes place at two different fluid level values.

When the magnetic field power between anchor (1) and release unit (5) is bigger than

the gravitational component

maintaining the release unit open, magnet (7) translation and consequent microswitches change

-

over succeeds (release).

When, during a further movement of the anchor (1), the gravitational component becomes bigger than the m

agnetic field

power, a back translation to the original magnet (7) position takes place, together with another consequent microswitches

change

-

over (disjunction). Release and disjunction points are not coincident because of the internal hysteresis inside t

he

item. Such item hysteresis is called “release differential”.

4. INSTALLATION

SET UP ON THE PLANT

- The installation point on the tank shall be far enough from any obstacle compromising the space necessary for

disassembly. Float (2) inside the tank shall be placed in an area free from any liquid turbulence. In case this won’t be

possible, protections will be provided in order to eliminate the mentioned turbulence.

- Always make sure the connection pipe is properly dimensioned, both in diameter and in length before installing the

item [float (2) has to go into the tank]; moreover, make sure the pipe is perfectly horizontal (max. 0.5° inclination) and

has max. 1° misalignment.

-

Level switch (7) is based on a functioning principle suffering the effects of c

onsiderable shaking and vibrations.