OFFICINE OROBICHE S.p.A. 2/3

24010 Ponteranica (BG) ITALY

-

via Serena, 10 Tel. 0039/35/453021

1 Fax 0039/35/570546

www.officineorobiche.it

e

-

*****************************************************************************************************************************************************************

JULY ’05

Under r

eserve of modification

IST/019

-I

5. STARTING UP

-

Make sure that the operating conditions do not exceed the rated values (higher pressure and temperatures, lower

specific gravity) and that the electrical rating is the correct one.

-

Test the instrument for correct switch

ing by changing the liquid level a few times.

6. CALIBRATION

The instrument is factory

-

calibrated and does not require any adjustments on the spot.

7. MAINTENANCE

Routine inspections should be carried out (every six months or so) to check the performance

of the instrument

from the time it is installed. The checks are simple and quick and are of two types: inspection of the body/float

and inspection of the contact.

WARNING

-

NEVER remove the cover before making sure that the power supply is disconnected.

-

NEVER leave the housing uncovered for longer than it takes to carry out the inspection.

-

NEVER use the instrument for pressure or temperature exceeding the rated values shown on the data plate.

-

NEVER use the instrument at higher electrical rating tha

n shown on the data plate.

-

NEVER carry out adjustments or replace parts before reading carefully the instructions. In case of doubt, check

with our aftersales service.

-

NEVER lubricate any of the instrument’s components.

- NEVER use the instrument in li

quids containing iron particles in suspension: the magnet might attract them and

cause the instrument to stop working.

-

If the instrument operates at high temperature, take all precautions to avoid any contact with hot parts.

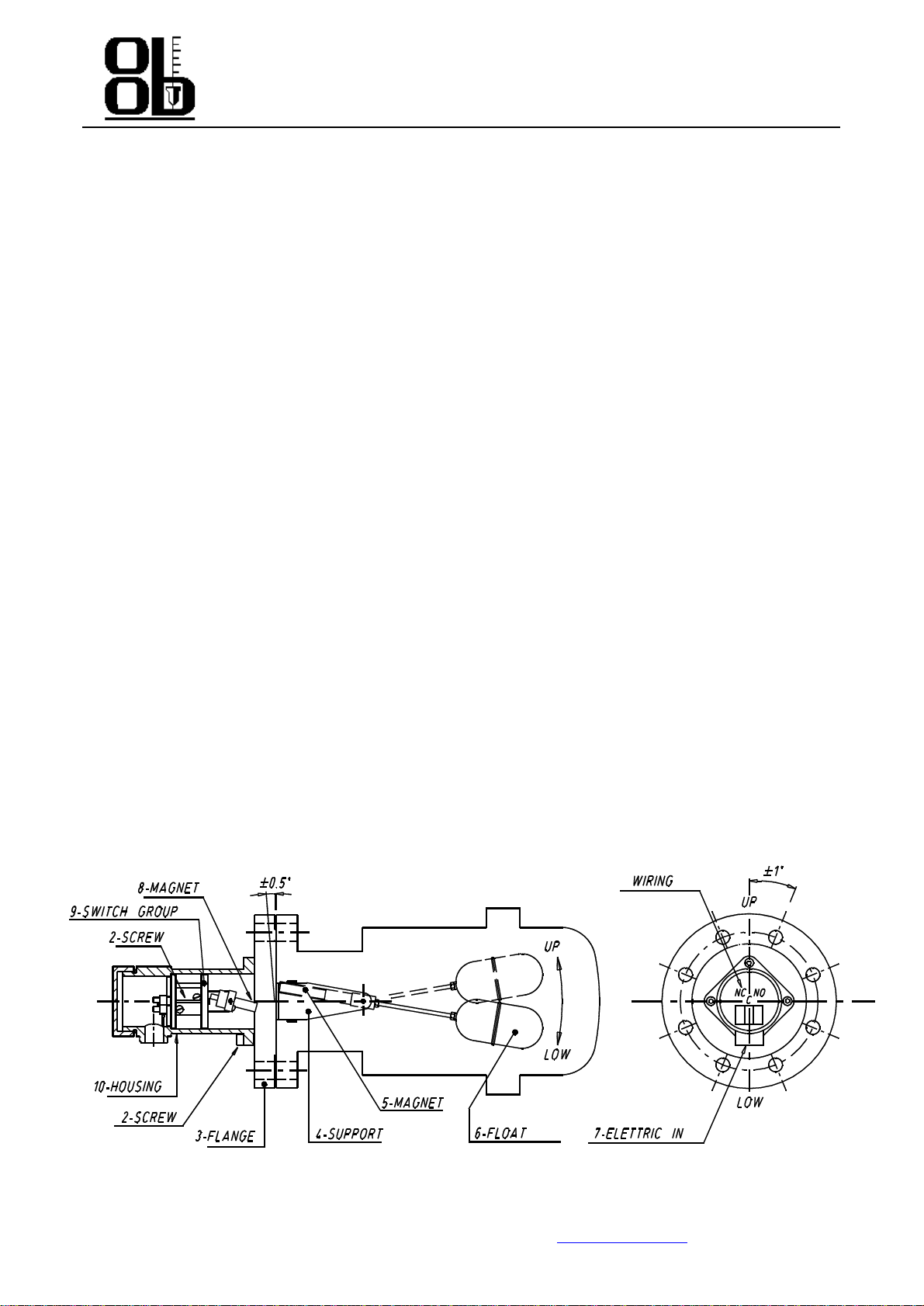

ROUTINE INSPECTION OF THE BO

DY / FLOAT

Carry out regular cleaning of the float (6) and of the magnet (5) on the fluid side. Make sure there are no scales or

filth between the magnet and the process flange (3) and between the magnet and the fulcrum supports (4) that

prevent the float

from moving freely.

ROUTINE INSPECTION OF THE CONTACT

When the instrument is removed for routine cleaning, move the float (6) manually to check that the microswitch

switch regularly.

REPLACING THE SWITCH GROUP

The microswitch is an integral part of the s

witch group and never needs to be removed. If the microswitch shows

malfunctioning, the whole switch group

-

supplied as a standard spare

-

needs to be replaced. Remove the housing

(10) from the process flange by means of the screws (1) which fasten it. Re

move the two screws (8) inside the

housing which fasten the switch group and extract it pushing from the terminal block side. Insert the new switch

group taking care that the terminal block is on the side of the electric input (7). The switch group is no

t reversible

and does not run properly if it is held upside down. Screw the unit together again and check for proper operation

like when executing routine inspections.

8. TROUBLE

-

SHOOTING

Series 10 level switches are designed for long fault

-

free life.

If a level switch does not emit the alarm signal, the

tripping unit should be checked and then the body/float as described in the preventive servicing paragraph. If the fault

is not identified after all tests have been carried out, please refer to our afte

r-

sales service.

9. WASTE DISPOSAL

Disposal of the instruments must comply with rules in force with regard to noxious toxic materials as well as to

special materials (PVC , PTFE , PP , PVDF , neoprene, viton , asbestos free joints, steel and metal alloys,

aluminium,

copper, brass, plexiglas and glass).