58700-0006-000 (Rev. 12) 08/2020

1.2 Warnings

This device should be repaired only by qualied Ohio

Medical or Ohio Medical-trained, qualied personnel,

using only Ohio Medical recommended parts. There

are risks associated with using anything other

than Ohio Medical parts. Ohio Medical will assume

no responsibility for incidents which may occur if

the product was not repaired in accordance with

procedures authorized by Ohio Medical.

If the vacuum regulator is repaired or disassembled

in any manner, the service checkout procedure

must be performed before using the equipment on a

patient.

After patient use, if regulator is contaminated then

handle in accordance with you hospital’s infection

control policy.

To reduce transportation personnel and/or service

personnel exposure to hazardous contamination,

DO NOT ship any suction equipment that has been

contaminated.

Do not use this device in the presence of ammable

anesthetics. Static charges may not dissipate and a

possible explosion hazard exists in the presence of

these agents.

Connection to positive pressure sources such as

oxygen and medical air, even momentarily, could

injure the patient or operator.

Ohio Medical will assume no responsibility for

incidents which may occur if the product is not used

in accordance with product labeling.

To help prevent aspirate from entering the device,

wall outlet and pipeline equipment, a safety trap

should be attached prior to its use. Aspirate in the

regulator, wall outlet and pipeline equipment may

impair its operations. The use of the safety trap and

suction lter will help prevent this and extend the life

of suction equipment.

1.3 CAUTION

Do not use any Loctite® products or any products

which contain Methacrylate Ester as an active

ingredient to seal the threads on the adapters/probes

and ttings.

Use of lubricants other than recommended may

degrade plastic or rubber components.

Do not steam autoclave or liquid sterilize the

regulator. Severe impairment to the operation of the

regulator will result. Do not use harsh chemical or

cleaning solution. Do not spray cleaners directly onto

suction regulators. Only use chemical recommended

in this manual.

If any evidence of damage is found, repair as

necessary or contact your authorized service

provider.

Connection to positive pressure sources such as

oxygen and medical air, even momentarily, could

damage the equipment.

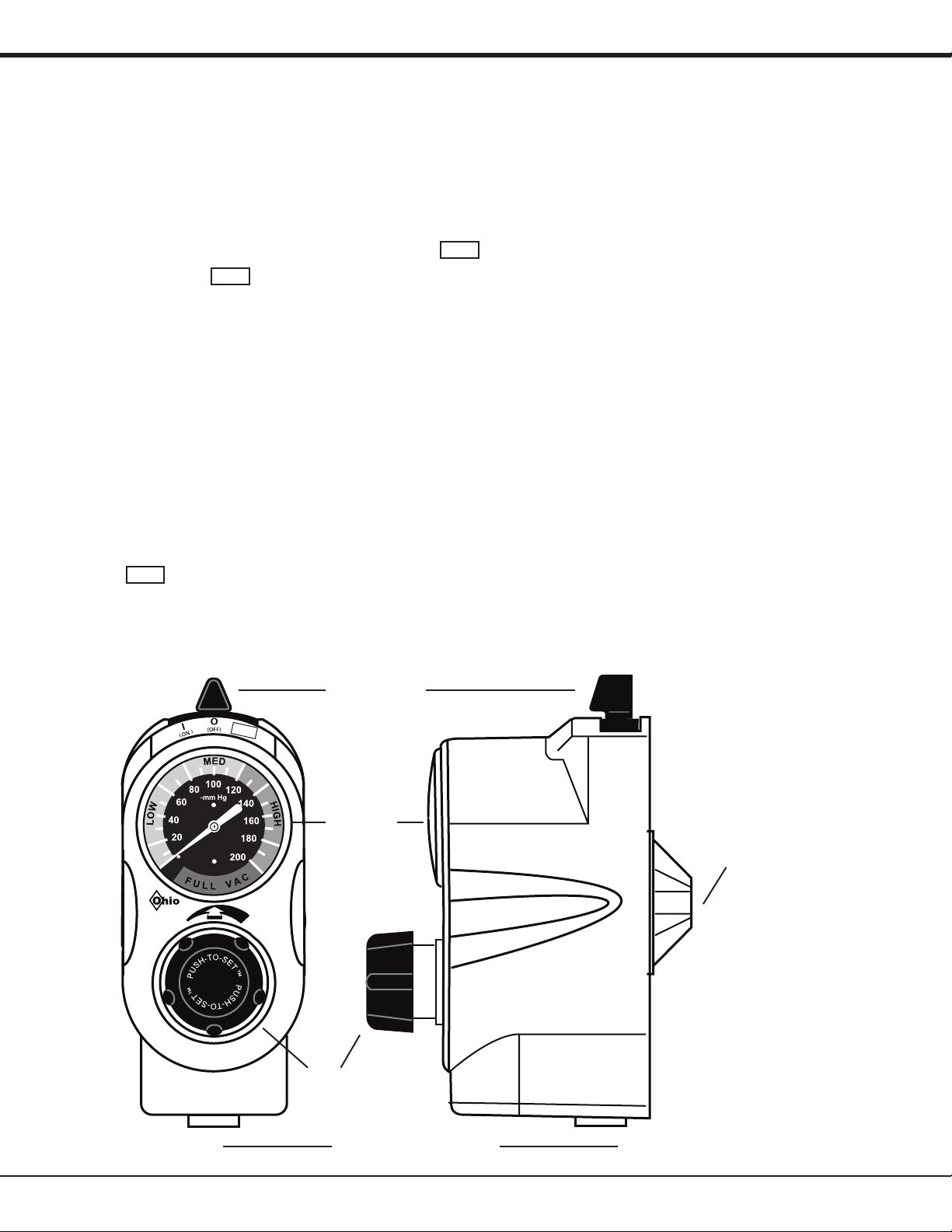

The suction control knob must be completely pushed in to

adjust the vacuum level. Failure to do so may damage the

vacuum regulator.

Not for transport use: The categories of eld and

transport user are specically dened in ISO 10079-

3. “Field” means use at accidents or emergencies

outside a hospital. “Transport” means use in

ambulances, cars and airplanes. These situations

may expose the equipment to uneven support,

water, dirt, and mechanical shock and temperature

extremes. Ohio Medical Suction equipment has not

been tested to comply with the specic requirements

of these categories.

Note: Ohio Medical requests that parties acquiring

this device:

Report the device’s purchase, receipt in trade, return

after sale, loss, destruction, or retirement.

Contact your Ohio Medical customer service

representative to obtain manual updates.

Authorized Service Center / Customer Service

Call 1-866-549-6446 or +1 847-855-0500 for service

and repair information.

1/Precautions