8

OPERATING INSTRUCTIONS

1. Make sure the alkaline batteries

have sufficient power. The display

will show the low battery symbol if

the batteries are inadequate. If the

instrument has not been used for

a period of time, the batteries

should be checked and replaced if

necessary. If desired, the AMM-15

can be operated from the AC

Adapter (it does not charge the

batteries). As with all such equip-

ment, if the unit is not to be used

for an extended period, the batter-

ies should be removed.

2. Purge the air line to be tested of

any water, oil, or other foreign

matter. The sensors are suscepti-

ble to contamination and damage

from impurities such as water, oil,

dust, chemicals, etc. THE PRO-

VIDED FILTER MUST BE BE-

TWEEN THE AMM-15 AND THE

SYSTEM BEING SAMPLED

FROM. FAILURE TO USE THE

FILTER VOIDS THE WARRAN-

TY. OHMIC INSTRUMENTS IS

NOT RESPONSIBLE FOR MIS-

USE OR NEGLECT OF THE

UNIT.

3. Connect the AMM-15 to the air

line following the recommenda-

tions on the Sample Modes /

Connecting Information page.

[AIR LINE PRESSURE IS NOT

TO EXCEED 120 PSI]

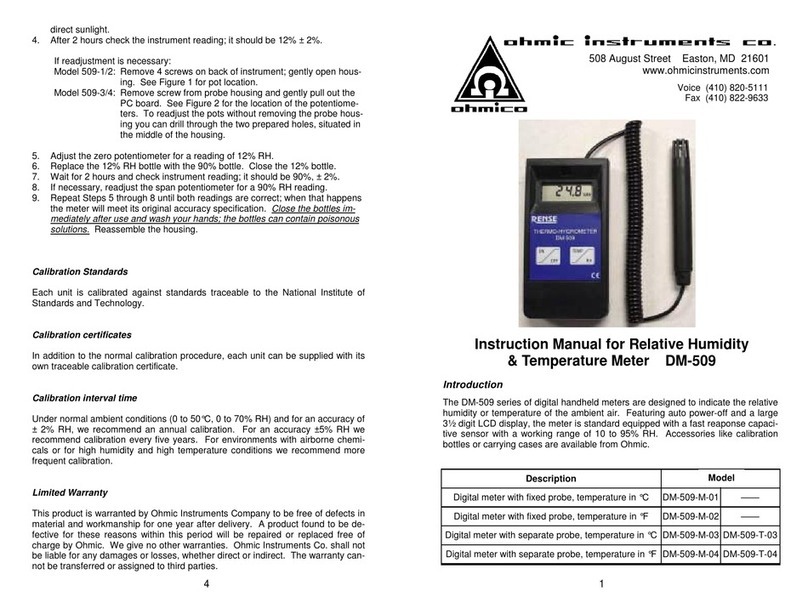

4. Press the ON button. The AMM-

15 always displays Dewpoint on

power up. The DP / DB selector

button will change the displayed

parameter from Dewpoint to Dry

Bulb Temperature. The display

will show a "down" arrow when

displaying Dewpoint and an "up"

arrow when displaying Dry Bulb

Temperature. The °F / °C selector

button will change the displayed

parameter from degrees Fahren-

heit to degrees Celsius.

5. Allow sufficient time for the read-

ings to stabilize. Normal stabiliza-

tion will occur within 1 to 1-½

minutes. Very low readings, less

than -10°F DP, will take up to 10

or 15 minutes for stabilization.

Analog Output

The AMM-15 provides an analog

output of 0-1 VDC (from –55 to +95°

F Dew Point). Use the enclosed 2-

wire plug adapter, and connect a

voltmeter to the wires: Red/white to

positive (+) and black/white to nega-

tive (-). Plug the adapter into the jack

marked Analog Out, and see the

table on Page 13 for values.

RS-232 INTERFACE– Connect-

ing the AMM-15 to your Comput-

er

Connecting to a serial port The

AMM-15 can be plugged into any 9-

pin PC serial (COM) port using a 9-

pin serial cable, available from most

computer stores. If your computer

has a 25-pin COM port, 25-pin to 9-

pin serial adapters are also available

from most computer stores and can

be used with the cable [Serial data is

transmitted using Pin 5 (ground), Pin

3 (transmit), and Pin 2 (receive)].

Some computer COM ports and seri-

al adapters are not fully implemented

(not all pins are used). If the AMM-15

is connected to a partially implement-

ed serial port, functions may be errat-

ic or the unit may fail to communi-

cate. Please consult the owner’s

manual for your computer if this oc-

curs. Set up your communications

program as described on the next

page.