5

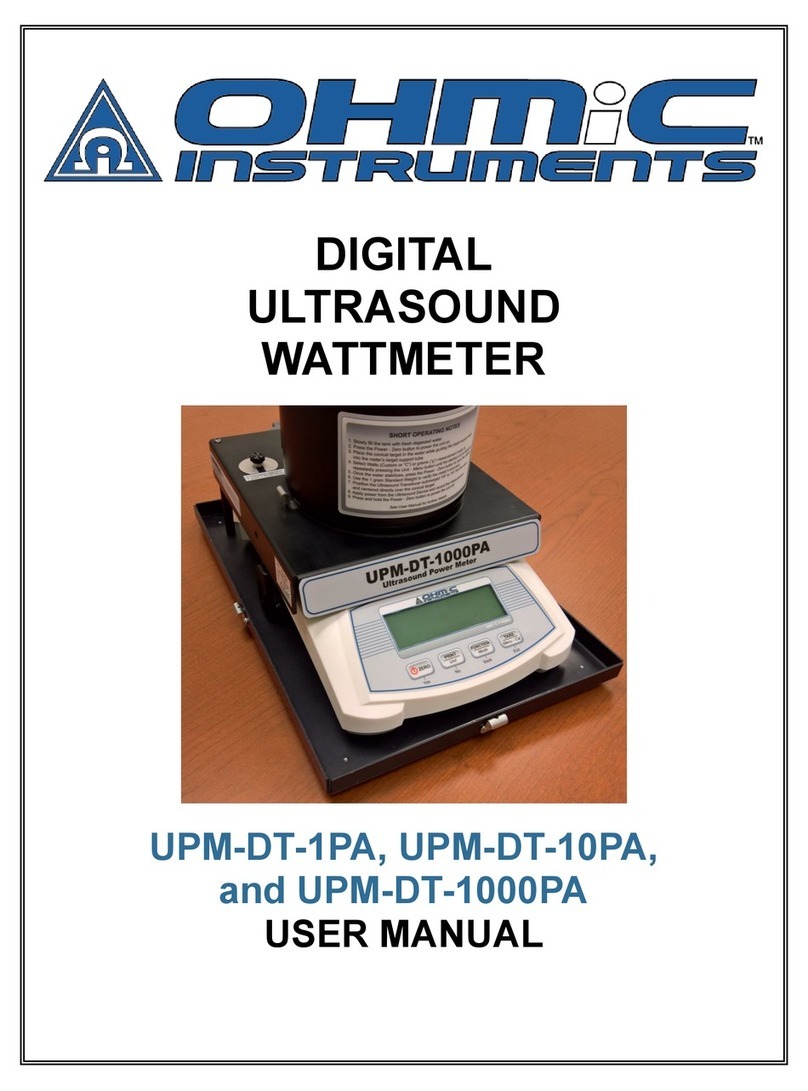

INTRODUCTION

The Ultrasound Power Meter, Model UPM-30, is a time-

tested instrument designed to measure the ultrasonic

power output of diagnostic or therapeutic transducers up

to 30 watts using the radiation force balance method.

The UPM-30 consists of a precision mechanical balance

which measures from 0.01 to 10.00 grams, a conical tar-

get suspended on a bracket, a water tank, a transducer

support rod with clamp, and a carrying case. The trans-

ducer to be tested is center-mounted over the conical

target with the transducer’s radiating area immersed face

-down in the water medium.

The Model UPM-30 Ultrasound Power Meter measures

the average ultrasonic power by measuring the radiant

force exerted by the transducer on the conical target.

This target is coupled to the precision mechanical bal-

ance which is used to measure the gram-mechanical

force due to the ultrasonic radiation. The gram force is

directly proportional to the ultrasound power in watts

when multiplied by a constant of 14.65. Therefore, a

2.05 gram force would be equal to 30 watts of ultrasound

radiation.

The heart of the UPM-30 system is its air-filled conical

target. The weight of this target is nulled to a minimum

by using its own buoyancy. Incident ultrasound energy is

mechanically transferred from the target to the precision

balance where it is manually measured. Reflected ultra-

sound energy is absorbed by a rubber wall inside the

water test tank. This system provides a sturdy instru-

ment with good measurement accuracy and low cost.

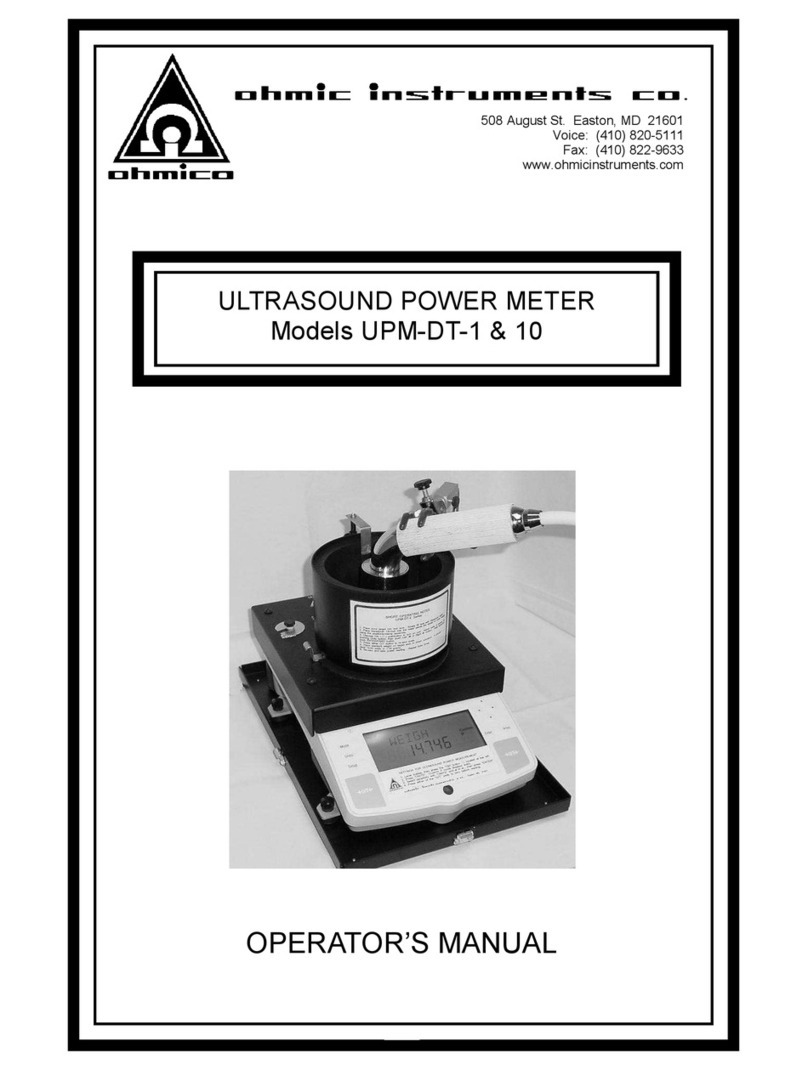

SETTING UP THE UPM-30

1. Remove and carefully unpack the conical target

stored in the test tank. Set the target aside until the

tank is filled.

2. Slowly pour recently degassed water into the test

tank and avoid any turbulence which might produce

air bubbles. Fill the test tank to approximately ½

inch from top of tank. The water must be at room

temperature. If degassed water is not available,

sterilized or distilled water may be used; however, a

small error of approximately 3 to 5% may be intro-

duced above the 10 to 15 watt output level.

3. Immerse the conical target into the test tank at an

angle to avoid any air bubbles from being trapped

under the target. Shake the target gently to release

any attached air bubbles. Position the cone target

so it is pointed upright in the center of the tank.

4. A bracket is attached to the conical target using ny-

lon cord. Place this bracket on the upper (or lower)

hook of the precision balance. Verify that the cone

target is centered in the test tank and does not touch

the sides of the tank.

5. Release the spring lock on the precision balance.

6. Balance the scale with the target in place and no

ultrasound power applied. Each UPM-30 system is

set up and balanced at the factory before shipping.

The weight of the conical target, when suspended in

the test tank, is measured, recorded, and marked on

the balance. This is a “zero” or “null” reading and is

approximately 1.5 grams. This weight is a constant

which must be subtracted from all readings when

measuring with this system. If a new target is or-

dered, be sure to indicate this null reading so an

equivalent target can be supplied.

7. To verify the scale’s accuracy, weigh the supplied 1-

gram standard (located on the base plate below the

short instruction notes) by placing it on the cone

bracket or on one of the scale hooks and rebalancing

the scale. The reading should be 1.00 gram higher

than the null reading.

8. When the UPM-30 is not in use, store the target and

bracket inside the test tank and replace the water-

tight lid. The lid will restrain the water during transit,

reduce the absorption of air into the water, and pre-

vent water contamination from foreign particles.

Note: If the unit will not be used for an extended pe-

riod of time, it is highly recommended that the water

be removed from the tank and replaced when use is

required.