7

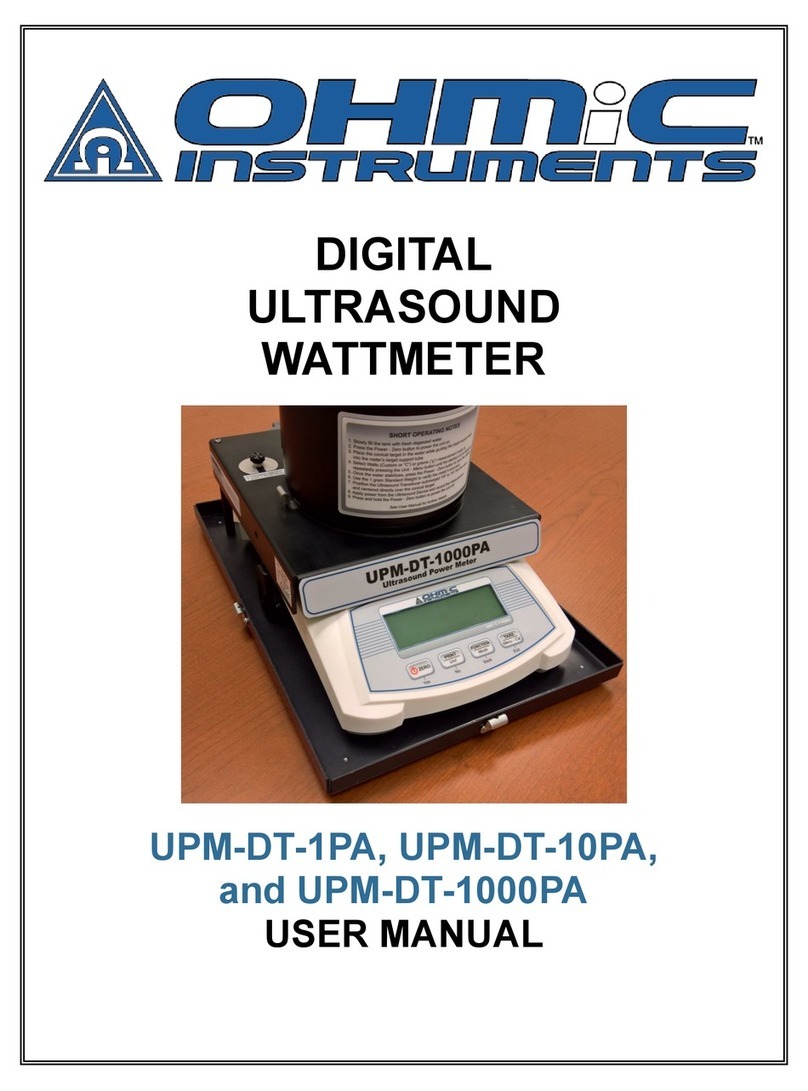

OPERATING PROCEDURE

1. Remove the top of the carrying case by unlatching

the clamps located on each side. The Ultrasound

Power Meter is mounted on the base of the carrying

case. For all applications, the unit must be re-

moved from the carrying case base, by removing

the 4 thumbscrews at the sides of the unit.

2. Place the UPM-DT on a stable and level surface

(use the Leveling feet and indicator on the unit).

Avoid air currents and mechanical vibrations. Level

unit as much as possible.

3. Loosen the positioning clamp and remove target

from the test tank where it is normally stored.

4. Place the back of the tank against the target sleeve.

Lower the target rod into the concentric test sleeve

located behind the test tank, which simultaneously

place the cone target into the tank. If the cone can

swing in an arc, it is not down far enough. Tip the

rod back slightly to fully engage the rod.

5. Fill the test tank to ¼ inch below the top of the rubber

liner with recently de-gassed water at room tempera-

ture. (To obtain de-gassed water, boil distilled water

for 20 minutes, fill a jar completely, cover surface

with saran wrap, and allow to cool)

6. By means of the positioning clamp, attach the trans-

ducer head and place its radiating face 1/8” to 1/4”

inch below the water level, parallel to the water sur-

face, and directly above the center of the cone.

Check transducer surface for uniform wetting (no air

pocket or bubbles should be on its surface).

7. Plug the line cord/adapter into a 120 VAC, 50/60Hz

power outlet and depress the ON/OFF button.

8. Allow 5 minutes for the scale to stabilize. With no

ultrasonic power applied to the transducer, press

either of the two O/T buttons to zero the unit.

9. Check response using the 1 gram weight. 1 gram is

equal to 14.65 watts.

10. Apply power to the Transducer Under Test (TUT).

Re-zero before each measurement and take your

power reading when the display has stabilized. De-

termine the maximum peak power with the maximum

duty cycle and pulsed output settings with the equa-

tion:

PAVE = Pp ÷ Rtpa

PAVE = calculated average power

Pp = Peak Pulsed Power Setting on unit under test

Rtpa = Ratio of Temporal Peak to Average Power (from

each manufacturer)

11. To calculate the watts/cm2 output, take the total watts

reading from the unit and divide by the area. The

area is d2÷ 4 (d is the diameter of the trans-

ducer) if the transducer is smaller than the cone.

Otherwise, use cone area.

12. After tests are completed, unplug the meter, empty

the tank, and place the dry target cone in the tank for

protection.

TRANSPORTING THE UPM-DT

Lift off the target cone assembly from the sleeve, empty

water into a sealable container, dry the tank and cone,

place cone in the tank and clamp the target rod into the

storage clips on the side of the target sleeve. Rotate the

transducer clamp arm over the top of the tank and

stretch the large rubber band between the two hooks of

the hold-down clip, over the clamp arm and tank. Place

unit on base of carrying case and secure it on posts us-

ing knobs provided (for shipping instructions see Page

11).

GENERAL OPERATING NOTES

Line Power / Voltage: UPM-DT Series meters are set to

operate on 12 VAC 50/60Hz. The unit is supplied with a

120 VAC adapter. Check for correct line voltage before

use. For voltages 220/240 VAC, an optional power

adapter and line cord are required.

Measurement Range, Watts & Grams: Model UPM-DT-

10 has four ranges. When Custom P is showing, the

UPM-DT-10 displays watts with a resolution of ± 20 milli-

watts or ± 0.02 watts. When the grams indicator gis on,

the resolution is 10 milligrams (± 0.01 gram). Each gram

equals 14.65 watts and 10 milligrams is equivalent to

146.5 milliwatts (rounded to 0.14 watt). Use Custom C

mode for most therapy equipment testing. If measure-

ment conditions are not stable, use Unit N or Grams

mode (when using the grams mode multiply the readings

by 14.65 to obtain watts).

Model UPM-DT-1 also has four ranges. When watts or

milliwatts are being measured, a Unit indicator below the

display will illuminate. Unit P appears for ±2 milliwatt

resolution; Unit C gives ±10 milliwatts, and Unit N dis-

plays to the nearest ±0.1 watt. Use Unit C and Nfor all

measurements except the lowest range requiring Unit P

mode. When the gram gsign appears, the display gives

readings to the nearest ±1 milligram. Each milligram cor-

responds to 14.65 milliwatts. Depressing the Units but-

ton, then or buttons will select the desired range.

Re-Zero / Tare: By depressing the O/T button, the

meter will zero at the present balance condition. During

re-zeroing, the display will be blank until the microproc-

essor senses a stable condition. If no ultrasound force is

applied, then the display will simply indicate true zero

reference; otherwise the applied ultrasound will become

the offset zero reference. This feature is convenient for

automatic zero setting before taking a reading, but also

to balance out a fixed ultrasonic power setting and to

measure incremental ± deviation from this mean setting.