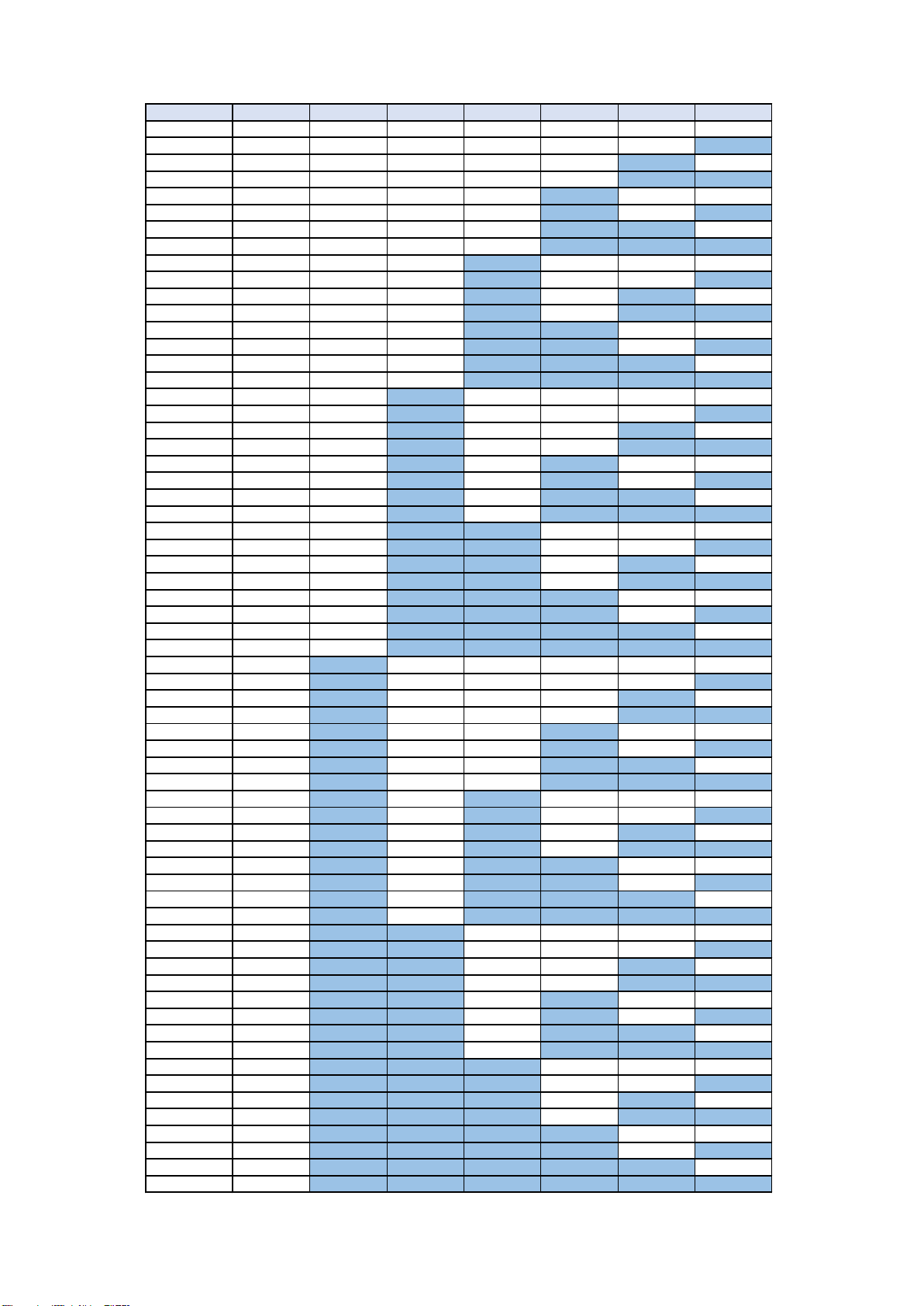

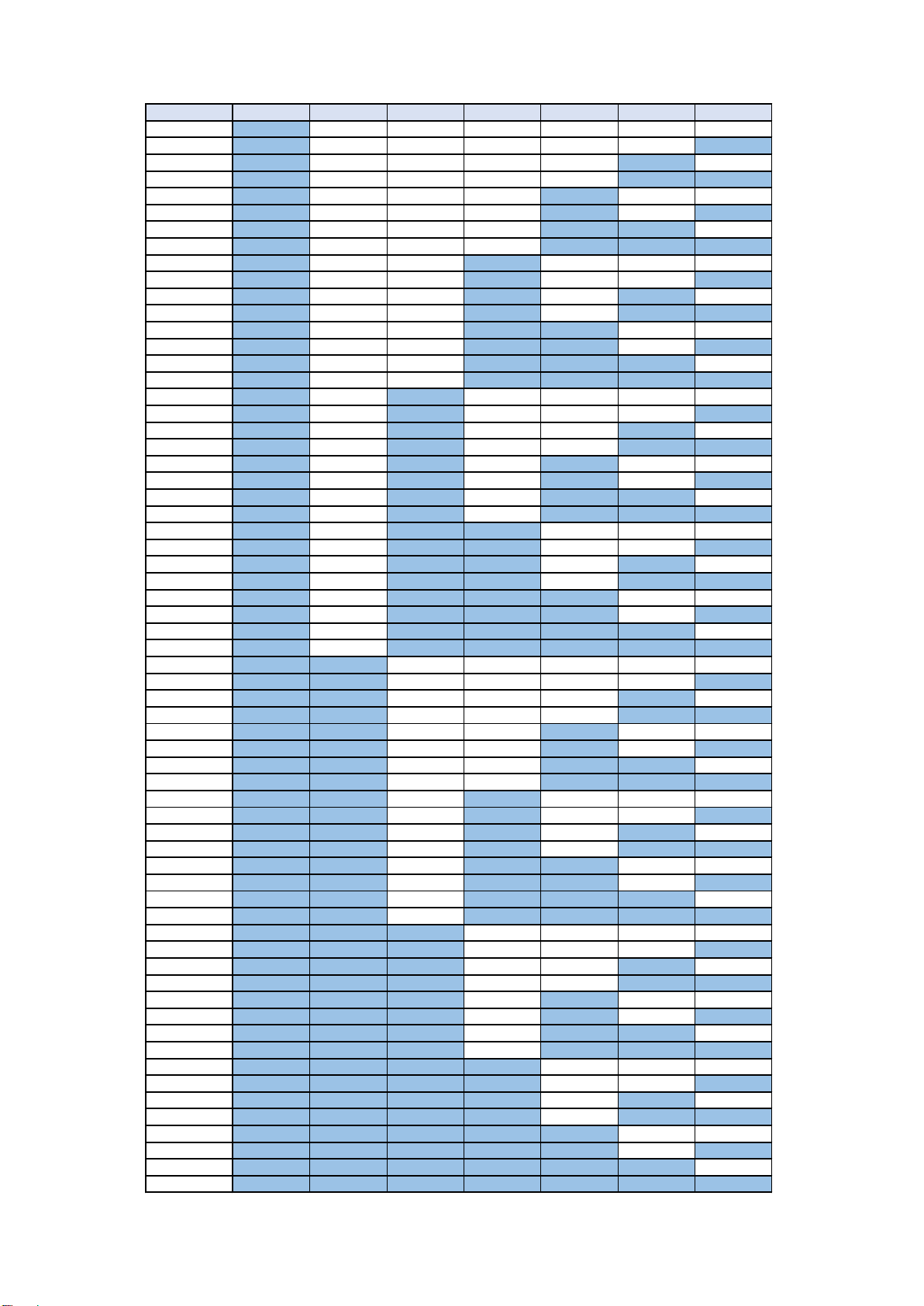

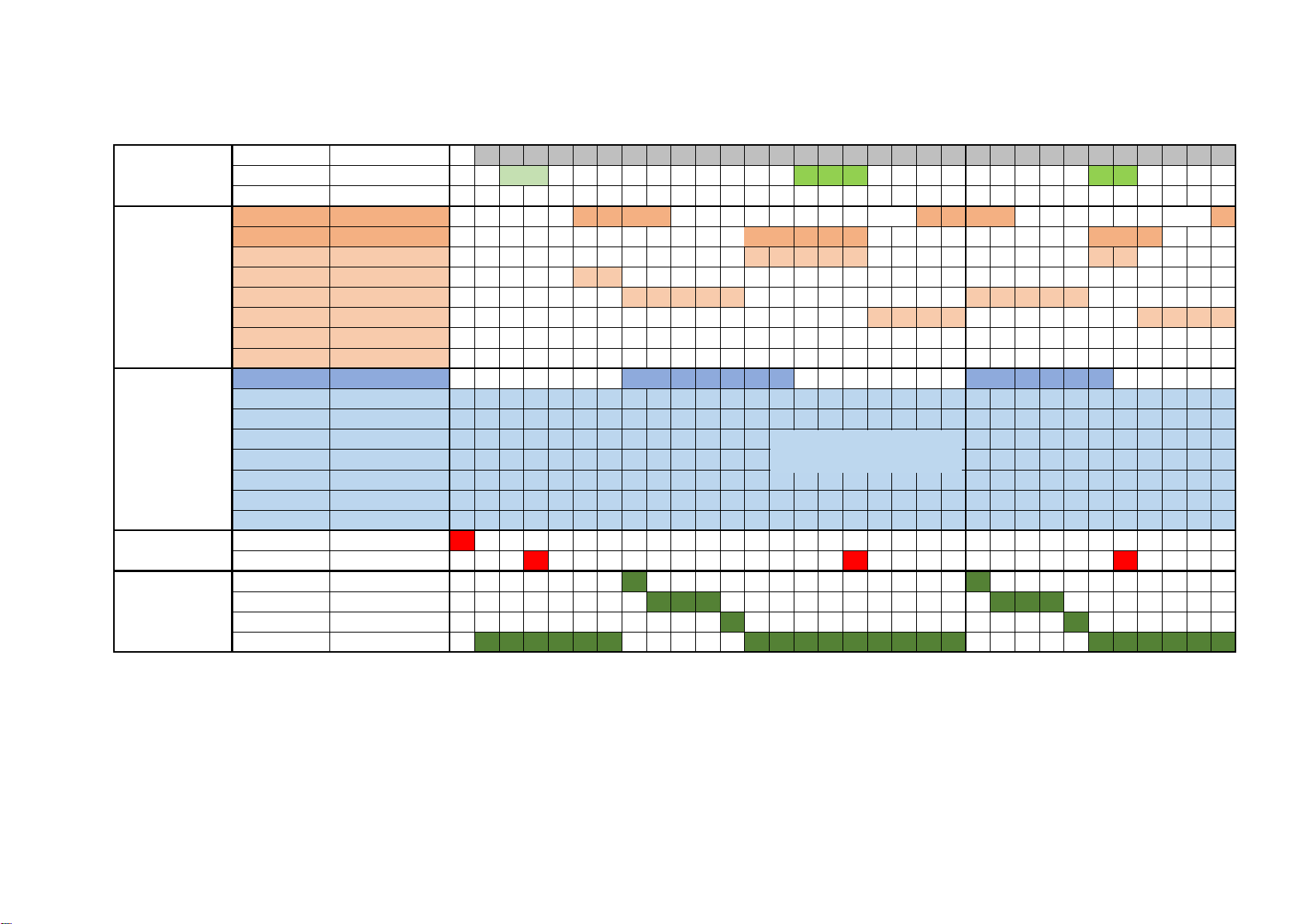

設定数 IN8 IN7 IN6 IN5 IN4 IN3 IN2

65 Low HI HI HI HI HI Low

66 Low HI HI HI HI Low HI

67 Low HI HI HI HI Low Low

68 Low HI HI HI Low HI HI

69 Low HI HI HI Low HI Low

70 Low HI HI HI Low Low HI

71 Low HI HI HI Low Low Low

72 Low HI HI Low HI HI HI

73 Low HI HI Low HI HI Low

74 Low HI HI Low HI Low HI

75 Low HI HI Low HI Low Low

76 Low HI HI Low Low HI HI

77 Low HI HI Low Low HI Low

78 Low HI HI Low Low Low HI

79 Low HI HI Low Low Low Low

80 Low HI Low HI HI HI HI

81 Low HI Low HI HI HI Low

82 Low HI Low HI HI Low HI

83 Low HI Low HI HI Low Low

84 Low HI Low HI Low HI HI

85 Low HI Low HI Low HI Low

86 Low HI Low HI Low Low HI

87 Low HI Low HI Low Low Low

88 Low HI Low Low HI HI HI

89 Low HI Low Low HI HI Low

90 Low HI Low Low HI Low HI

91 Low HI Low Low HI Low Low

92 Low HI Low Low Low HI HI

93 Low HI Low Low Low HI Low

94 Low HI Low Low Low Low HI

95 Low HI Low Low Low Low Low

96 Low Low HI HI HI HI HI

97 Low Low HI HI HI HI Low

98 Low Low HI HI HI Low HI

99 Low Low HI HI HI Low Low

100 Low Low HI HI Low HI HI

101 Low Low HI HI Low HI Low

102 Low Low HI HI Low Low HI

103 Low Low HI HI Low Low Low

104 Low Low HI Low HI HI HI

105 Low Low HI Low HI HI Low

106 Low Low HI Low HI Low HI

107 Low Low HI Low HI Low Low

108 Low Low HI Low Low HI HI

109 Low Low HI Low Low HI Low

110 Low Low HI Low Low Low HI

111 Low Low HI Low Low Low Low

112 Low Low Low HI HI HI HI

113 Low Low Low HI HI HI Low

114 Low Low Low HI HI Low HI

115 Low Low Low HI HI Low Low

116 Low Low Low HI Low HI HI

117 Low Low Low HI Low HI Low

118 Low Low Low HI Low Low HI

119 Low Low Low HI Low Low Low

120 Low Low Low Low HI HI HI

121 Low Low Low Low HI HI Low

122 Low Low Low Low HI Low HI

123 Low Low Low Low HI Low Low

124 Low Low Low Low Low HI HI

125 Low Low Low Low Low HI Low

126 Low Low Low Low Low Low HI

127 Low Low Low Low Low Low Low

Appendix 2. Screw number settings and Input signals.