1. Description.

The WSD12-2DI is a datalogger with two input channels to acquire pulses from clean contacts or open-collector, from energy meters, fluid

meters, etc. inputs, with storage functionality of samples acquired.

Counting is continuously performed on input channels and is partially considered on the configurable

sampling period. In case, counting can be set as aggregate and scalable.

Data are wireless transmitted and internally stored.

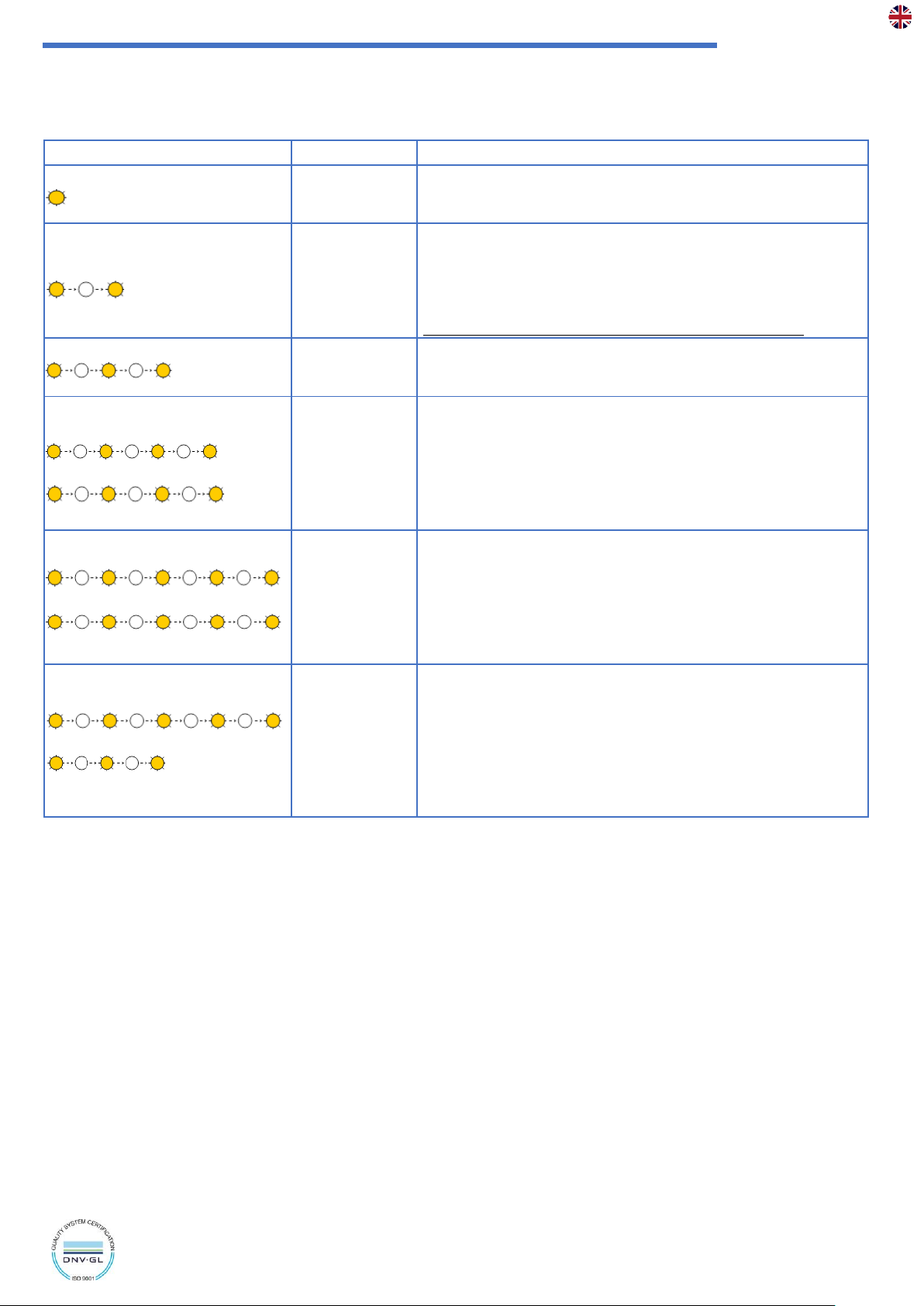

2. Sampling

In normal mode, the measure acquired is related to pulses counted in the programmed sampling

interval.

At the end of each interval, the counted value, multiplied by the energy weight, is transmitted to the

gateway,and internally saved.

After which, the counter is reset, and a new integration cycle starts.

In cumulative mode, count is maintained and is automatically updated to new value at each measure

interval.

Value can reach overflow; in case, counter resets and automatically starts again when reaches the

maximum value of 65,535 pulses.

Sampling time is selectable and adjustable by radio but is recommended to set a time and maintain

it fixed for the complete measure harvest to guarantee values and intervals homogeneity.

To perform an analysis in an established period, a summation of whole contributions coming from each interval is needed.

In normal mode, performing a graphical analysis of samples, is easily possible to compare higher impact pulse periods with lower impact ones,

obtaining the measure timing profile, locating peaks and lowest periods.

To obtain the total amount in a period, a sum of samples acquired in the period can be performed.

NOTE: if the gateway analog output is coupled to the datalogger’s meter channels, the expected output signal will be a tier where each level

represents the recorded energy in the previous period

A punctual evaluation of

weight

/

pulse

/

sampling interval

/

maximum output signal amplitude

parameters is necessary to obtain best dynamic

results and avoid signal saturation.

With the same sampling interval, and consider the in-use amplitude scale, a wave integral calculation is possible, obtaining the energy counted

on a longer period.

3. Configuration.

The datalogger can be configured to sample:

•Active energy [

KWh

], Reactive energy [

Kvarh

] and Apparent energy [

Kvah

]

•Thermal energy [

KWh

]

•Fluid volume [

l

]

•Generic pulses

•Cumulative generic pulses

The pulse weight is adjustable to align the channel’s measure to connected measurer’s features to obtain correct reads.

Generic pulse hasn’t measure unit so, in case of cumulative mode configuration, weight is used as de-multiplier capable to scale value

represented by measure and reduce the overflow frequency.

Each channel can be configured independently to adapts to different pulse sources.

To perform the configuration, the datalogger must be connected to a PC using a

USB

connection; if necessary,

DRIVERS

(

located on the

provided CD

) must be installed:

•open

WineCapManager

software

•select the connection type: choose “

Local Connection

”

•select the support database and click on “

Open

”

•select “

Properties

” from “

Sensor

” drop down menu then choose “

Tools

” tab (

Picture 2 - Datalogger configuration

)