Instructions manual / Electric screwdrivers

4

INDEX

1. Specification……………………………………………………………………………..……………………………………p.5

2. Main features of SCOUT II………………………………………………………………………………………….……… p.5

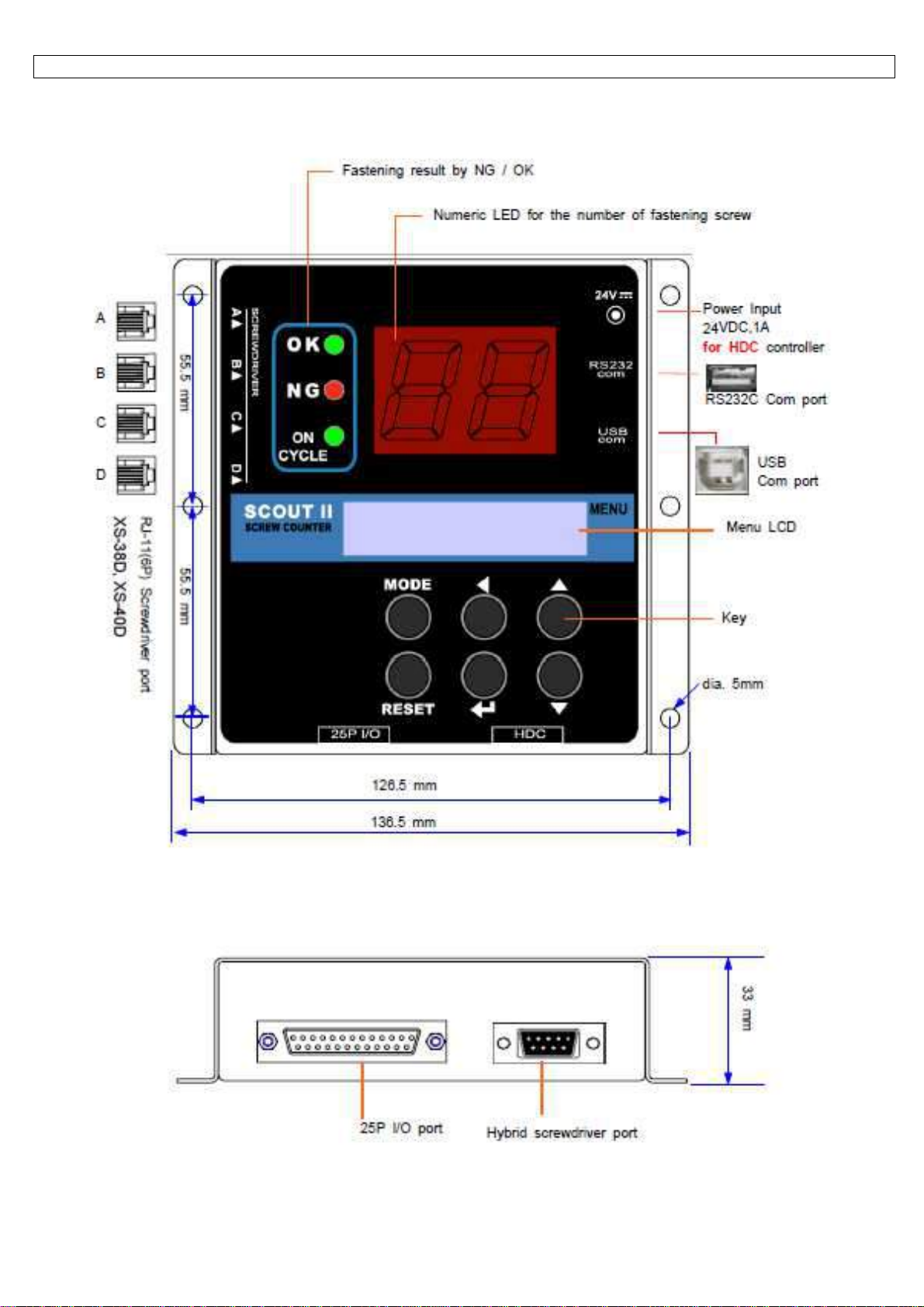

3. LAY OUT……………………………………………………………………………………………………………………...p.6

4. Caution……………………………………………………………………………………………………………………….. p.7

5. Accessories ( Option items )……………………………………………………………………………………………......p.8

6. Operation……………………………………………………………………………………………………………………...p.9

6.1 Mode………………………………………………………………………………………………………………………… p.9

6.2 Work mode…………………………………………………………………………………………………………………..p.10

6.3 Log-in mode ………………………………………………………………………………………………………………...p.10

6.4 Parameter mode…………………………………………………………………………………………………………….p.11

6.5 Measuring mod……………………………………………………………………………………………………………...p.12

6.6 Program # and parameters……………………………………………………………………………………………….. p.13

6.7 Parameters…………………………………………………………………………………………………………………. p.14

7. Interface……………………………………………………………………………………………………………………… p.17

7.1 25P I/O interface details……………………………………………………………………………………………………p.17

7.2 INPUT (Negative(-) Common wiring)……………………………………………………………………………………..p.18

7.3 INPUT (Positive(+) Common wiring) ……………………………………………………………………………………. p.19

7.4 OUTPUT (Negative(-) Common wiring) ………………………………………………………………………………… p.20

7.5 OUTPUT (Positive(+) Common wiring) ………………………………………………………………………………….p.21

7.6 Binary coding for Program selecting by 3 pins ( Pin no. 8,9 and 10 ) - P35 Enable..............................................p.22

7.7 Wiring example #1 - Tower lamp, solenoid valve, sensors, switch……………………………………………………p.23

7.8 Wiring example #2 - Inter-Lock of two screwdriver with Mid-Count signal setting…………………………………..p.24

7.9 Connecting to Hybrid HDC controller……………………………………………………………………………………..p.26

8. Timing Chart…………………………………………………………………………………………………………………. p.27

9. Timing chart details for NG / OK set up……………………………………………………………………………….......p.28

9.1 Fastening OK………………………………………………………………………………………………………………..p.28

9.2 Fastening ERROR 1 - TIME LAPSE……………………………………………………………………………………...p.28

9.3 Fastening ERROR 2 - TIME OVER……………………………………………………………………………………....p.29

9.4 Fastening ERROR 3 - NO TORQUE UP ( Most common mistake in assembly )…………………………………...p.29

10. Cycle Start / Stop in the various operating conditions……………………………………………………………........ p.30

10.1 Auto Start…………………………………………………………………………………………………………………..p.30

10.2 Start ( Continuous ON )…………………………………………………………………………………………………..p.30

10.3 Start (pulse) + Stop by time limit (Optional)…………………………………………………………………………….p.31

10.4 Start (pulse) + Stop (pulse)……………………………………………………………………………………………… p.33

11. RS-232C & USB communication port………………………………………………………………………………….... p.34

11.1 Protocol................................................................................................................................................................p.35

11.1.1 Protocol frame.................................................................................................................................................. p.35

11.1.2 Communication control letter............................................................................................................................p.35

11.1.3 Command.........................................................................................................................................................p.36

11.1.4 Check sum (BBC).............................................................................................................................................p.36

11.2 Parameter change and save................................................................................................................................p.36

11.3 Monitoring data output.........................................................................................................................................p.37

12. PC communication software, SCOUT II-Manager (for MS Windows)………………………......…………………… p.38

12.1 Software install…………………………………………………………………………………………………………….p.38

12.2 How to use…………………………………………………………………………………………………………………p.38