www.okinternational.com

8

3.0 Technical Data

Maximum airflow, free blowing............................. 250m3/h (150cfm)

Flow rate ..............................................................2 x 75 m3/h (45cfm)

Static pressure .....................................................850 Pa (3.5”WC)

Noise level (approx.) ............................................ < 55dBA

Voltage .................................................................100 – 240 VAC, 1 phase

Frequency ............................................................50-60 Hz

Motor rating ..........................................................85 Watts

Safety compliance................................................UL, CSA, CE

Dimensions W/D/Hmm.........................................508 x 254 x 388

Dimensions W/D/H in...........................................20” x 10” x 15.3”

Weight (approx.)...................................................20 lbs. / 9 kg

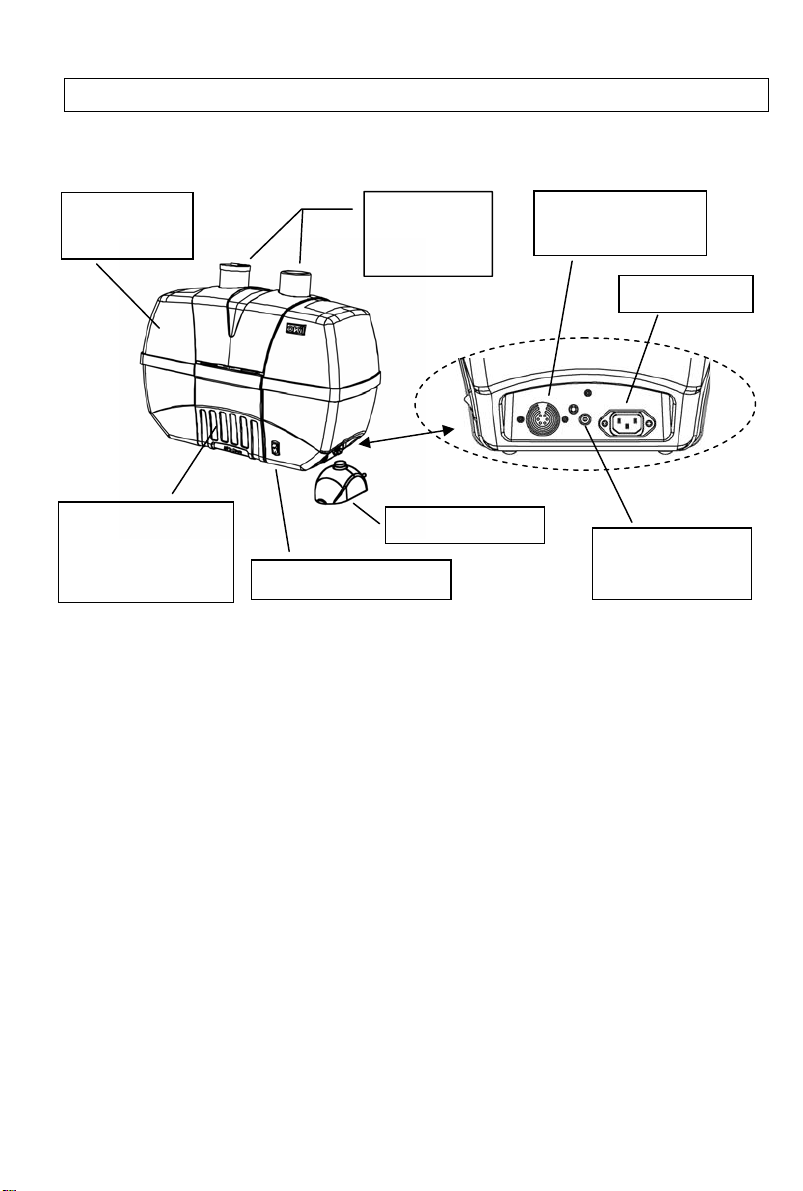

4.0 Installation

Remove the BVX-200 Fume Extraction System from packing materials and

place on the floor under workbench or near your work area where fume

extraction is required. Make sure you have access to the unit for filter

maintenance.

Connect the units’ power cord into the outlet on the side of the system. Plug

the power cord into a grounded wall socket.

Warning! To provide protection against the risk of electrical

shock, connect to properly grounded outlets only.

Connect the unit to arms/hose as per installation instructions.

To power up system, depress the power switch, located on the bottom right of

the unit. The operator can expect a delay of a few seconds before hearing the

motor running. This is due to the built-in motor “Soft-start” feature.

If utilized, connect the supplied remote Start/Stop switch to the system and site

the switch in a convenient position on the workbench. We recommend that this

switch be used for your convenience; the ‘On’ light will indicate the BVX-200

motors’ On/Off state and will ease switching without the need to bend under

the workbench.

Position the extraction arms to optimize fume capture.

Follow maintenance procedures on next page.

www.okinternational.com

9

5.0 Maintenance and Cleaning

5.1 Filter Unit - Maintenance and Safety

The BVX-200 Fume Extraction System is designed with low maintenance in

mind. The housing is ESD safe plastic. Here are a few tips to keep your system

running in top shape:

To clean, use a light wipe with a gentle cleaner to prevent build up of

particulate and flux residue (be sure unit is turned off while cleaning).

Do not block both of the inlets or exhaust outlets; this will cause:

•the operating temperature of the system to rise

•a false filter-block alarm,

•potential damage to the unit,

•a drop in performance.

Do not defeat the filter interlock switch. Running the system without a

filter will allow particulates and flux residue to adhere to the blower, decreasing

the life of the system and increasing noise.

Do not lift system while operating.

Be sure to handle filters with care.

5.2 Filter Replacement Timing

Model BVX-201

As fumes are filtered inside the unit, any particulates captured will, over time,

start to clog the filter. The coarse particles are collected in the pre-filter while

fine particles will be collected in the HEPA filter. This clogging will result in a

reduction of the airflow, which may reduce the amount of fumes extracted from

the work area. Once the filters start to become blocked an audible alarm will

sound in the main unit. This is to signify that filter replacement is required.

Initially replace the pre-filter only. If this does not silence the alarm, then

replace the main filter too.

Dependant on application, pre-filters should be replaced approximately three to

five times as frequently as the main filter. We recommend that a stock of

replacement filters be kept for optimal extraction performance and minimum

down-time. Part Numbers are shown in section 8.2 of this User Guide.

This Manual: http://www.manuallib.com/file/73175