2-2

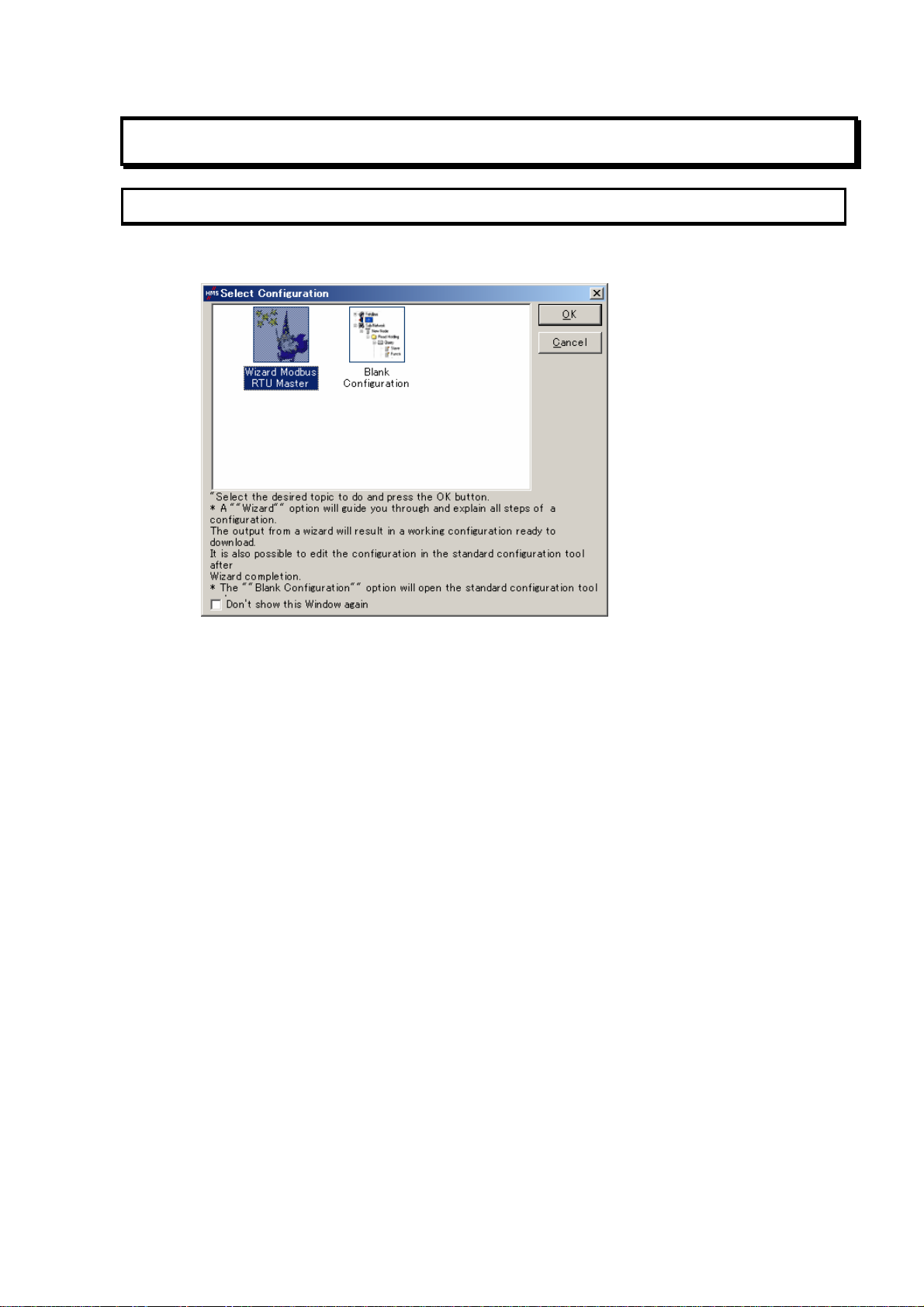

2.4. ABC Configuration Tool

"Configuration Tool for AnyBus Communicator 2.10" can be downloaded from the site of

HMS. Configuration Tool is common for all the fieldbuses.

http://www.anybus.com/eng/support/support.asp?PID=104&ProductType=AnyBus%20Communicator

2.5. ABC Configuration File

Configuration File which Okura Yusoki offers shall be used. You have to download this

file to new ABC once.

Profibus AbcRc101ProfiDp.cfg

Ethernet/IP AbcRc101EhernetIP.cfg

onoffln.cfg

2.6. GDS File

GDS File required for Configuration of a Profibus master can be downloaded from the

site of HMS. Profibus Gateway of ABC corresponds only to the slave of Profibus-DP.

Therefore, you have to prepare Profibus Master independently. The GDS file name is

HMS_1803.gsd.

http://www.anybus.com/eng/support/support.asp?PID=104&ProductType=AnyBus%20Communicator

2.7. PC

PC which can perform ABC Configuration Tool is required in order to communicate by

RS232C between PC and AnyBus, to be equipped with one RS232C port. Since a

USB-RS232C converter may not communicate correctly, a direct RS232C interface is

required for it. The following clause explains about a connection cable.

2.8. Configuration Cable

When purchasing from HMS Configuration Cable which connects PC and ABC, the

part.no 017620 shall be ordered. When manufacturing, it can make with reference to

Pocket Guide. It can be used for the configuration of other ABC only with this cable.

2.9. Attaching ABC

CE and UL controllers are equipped with the DIN rail to mount on. Refer to the Document

of AnyBus Communicator for the method of mounting the ABC in the DIN rail.

2.9.1. Connection and routing

Separate the electric wire linked toABC from power cable.