~2~

Stove Safety

When properly maintained and operated your stove should give you many years of service, however

there are important safety aspects of these products that you need to be aware of when operating a

1.

The term Multi-fuel refers to any of the main commercially available solid fuels such as coal,

wood, turf, anthracite, briquettes. Never use liquid fuels such as oil or kerosene when lighting

or refreshing the fire or at any other time. Do not store liquid fuels near stove.

2. The burning of wood gives off gases which can be extremely dangerous. The stove is designed

that under normal operating circumstances these gases pass up the flue chimney system and

cannot escape into your home, however it is important that your flue system is properly

installed and that you check all joints regularly to ensure that there are no cracks or gaps,

check the door sealing rope and replace when damaged. We recommend a smoke alarm be

fitted in rooms where stoves are installed. Do not use stove in a room where negative pressure

conditions may occur, such as through the use of extraction fans unless an adequate air supply

into the room is ensured, as this may draw air through the stove and cause products of

combustion to escape into the room.

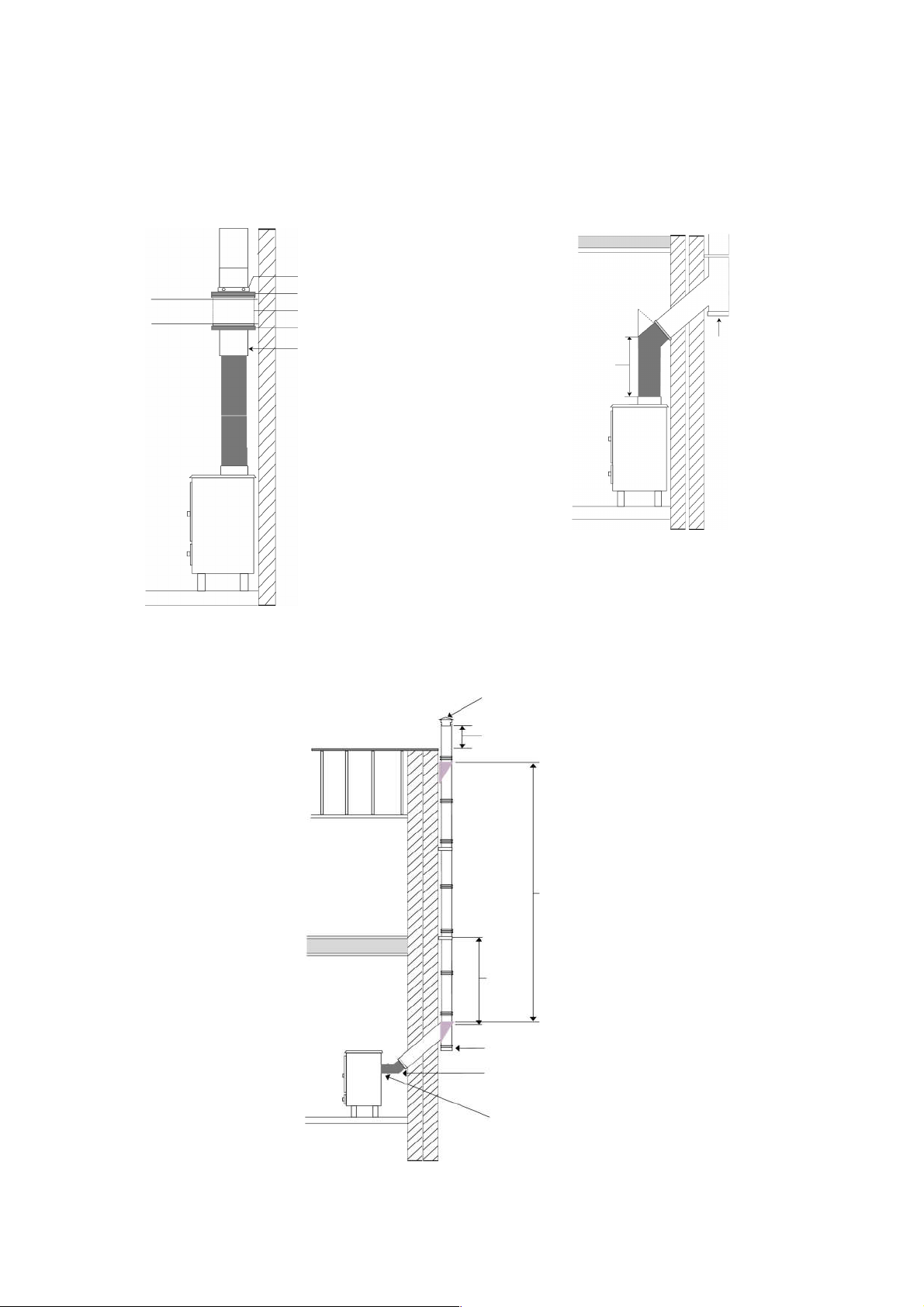

3. Creosote and soot may accumulate in your flue pipe and chimney. This may ignite, causing a

chimney fire. If you suspect a chimney fire evacuate people from the building, close down the

air controls on the stove and call the Fire Department. To prevent the accumulation of soot or

creosote, check flue and chimney regularly and clean as necessary. Good burning, hot stoves

will generally cause a lot less build-up than slow burning stoves, likewise dry wood will cause

less build-up than wet wood. We recommend a fire extinguisher be available where stoves are

in operation. In the event of a chimney fire do not re-light the stove until it and the flue

chimney system have been thoroughly checked and repaired as necessary.

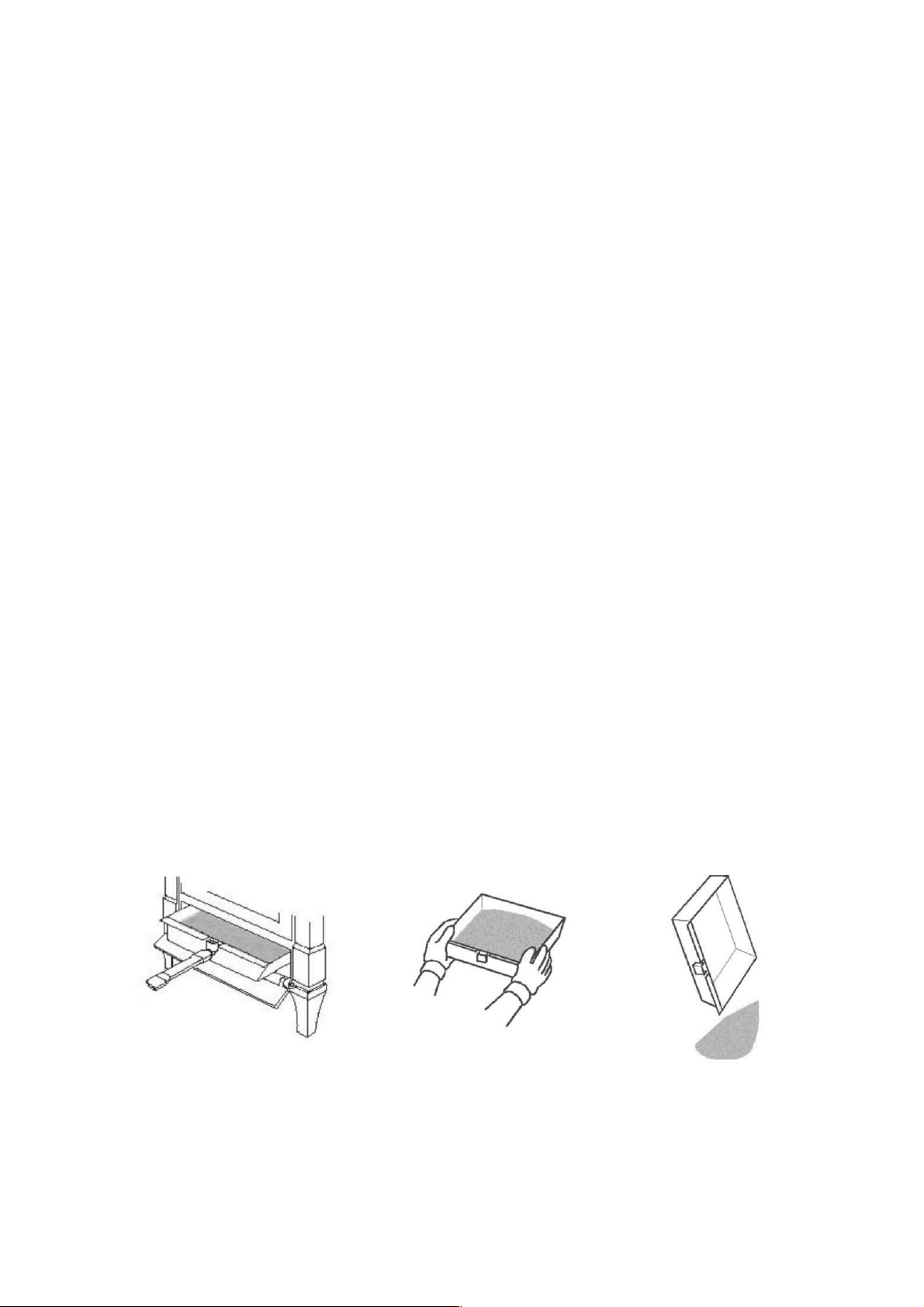

4. Stoves get extremely hot and should not be touched when lit. When young children are in the

area, we recommend the use of a suitable fire guard around the stove. Always wear protective

gloves when reloading stove.

5. Never over-fire your stove. If external parts of your stove are glowing red then the stove is

over-firing and your draught settings should be reduced. Never interfere with the draught

mechanisms or adjust your air settings outside those limits set when the stove is manufactured.

Never use a fan to supply air to the stove or to extract air from it.

6. All users of the stove should be aware of the contents of this manual. Please leave this manual

where it is accessible to stove users and do not allow anyone to use the stove that is unfamiliar

with its correct operation.

7. Never use the stove if any parts are missing or damaged, only use genuine parts as

replacements. Never modify your stove.

8. Never use a fan to supply air to the stove or to extract from it.