D878 MGB Rev00 HE650.docx 3/50

General Index

0General information ................................................................................................................................... 5

1General Infon............................................................................................................................................. 6

1.1 Warning on how to operate................................................................................................................ 6

1.2 Inspection on delivery........................................................................................................................ 6

1.3 Storage .............................................................................................................................................. 6

1.4 Disposing........................................................................................................................................... 6

1.5 Directives and technical standards considered ................................................................................. 6

2Schemes and adjustments ........................................................................................................................ 7

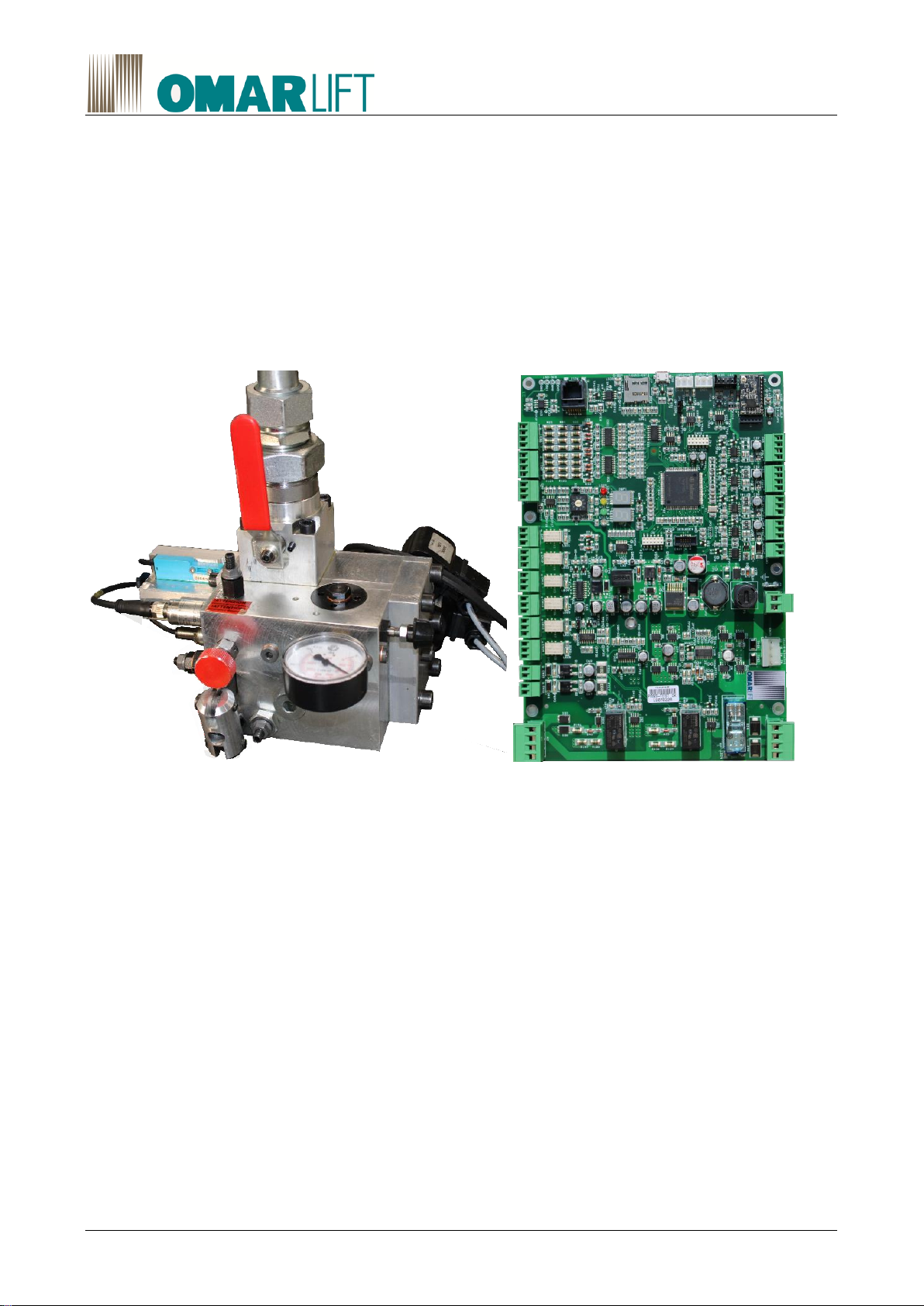

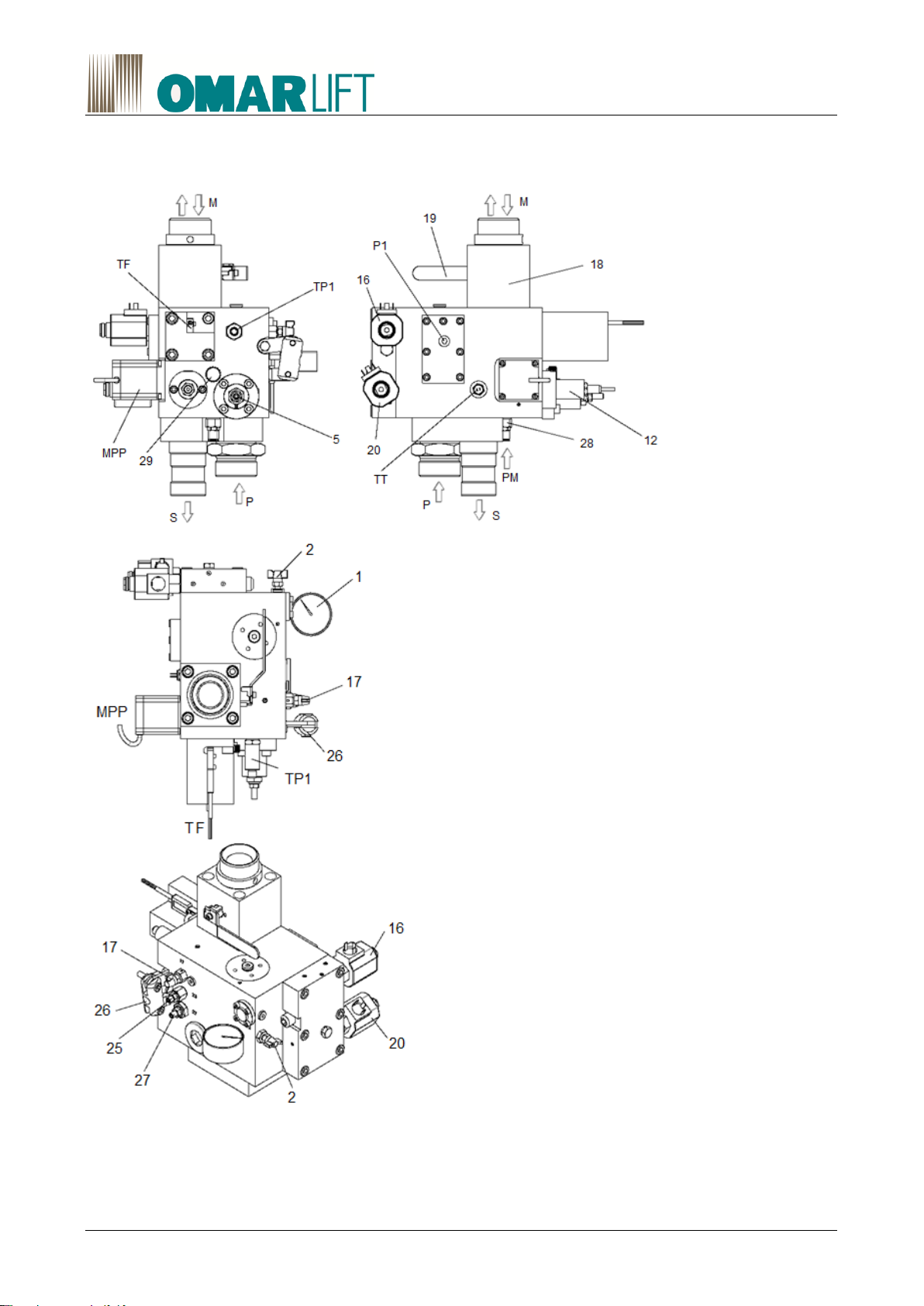

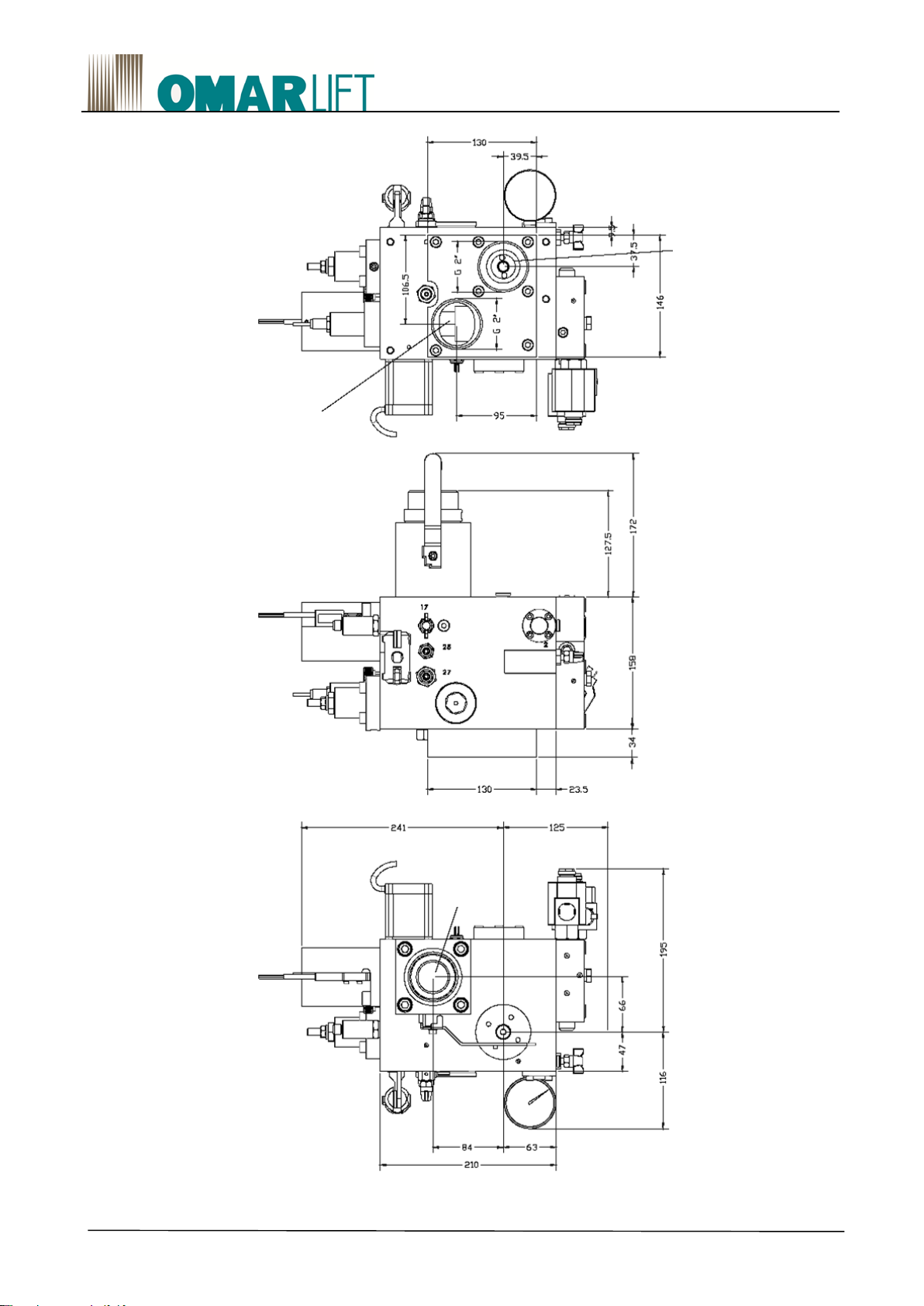

2.1 Main components .............................................................................................................................. 7

2.2 Hydraulic diagram.............................................................................................................................. 8

2.3 Valves functionaldiagram................................................................................................................... 9

2.4 Main components and connections of SCH001 board.................................................................... 11

2.5 Posizioni commutatore RSW........................................................................................................... 12

2.6 Wi-fi connection (Optional) .............................................................................................................. 12

2.7 SD-CARD parameters and records recovery.................................................................................. 12

2.8 SD-CARD parameters loading......................................................................................................... 13

2.9 Overload pressure automatic setting............................................................................................... 13

2.10 Software updating procedure........................................................................................................... 13

2.11 Working cycles parameters ............................................................................................................. 14

2.12 Signal and speed parameters combination..................................................................................... 15

2.13 Command device working diagram ................................................................................................. 16

2.14 SCH100 board dimensions and fixing ............................................................................................. 17

2.15 Upward working cycle...................................................................................................................... 18

2.16 Downward working cycle................................................................................................................. 20

2.17 Releveling........................................................................................................................................ 21

2.18 Rapture valve test (DSP=FC, FP) ................................................................................................... 21

2.19 Maximum pressure valve test (DSP=PP, HP)................................................................................. 22

2.20 Error condition ................................................................................................................................. 22

2.21 Upward working cycle diagram........................................................................................................ 23

3Protection against the uncontrolled movement of the cabin (UCM)........................................................ 24

3.1 Introduction...................................................................................................................................... 24

3.2 Schedule of operation signals and controls..................................................................................... 24

3.3 Test device against uncontrolled movement (DSP=uc, up ) ........................................................... 25

3.3.1 Ascent with empty car, and positioned in the upper part of the compartment ........................ 25

3.3.2 Descent with a full load in the cabin, and the cabin located at the bottom of the compartment

25

3.4 Self-control of type of functional redundancy .................................................................................. 25

3.4.1 Cycle with self monitoring functional redundancy.................................................................... 26

3.5 Verification of the periodic self-monitoring function of redundancy................................................. 27

3.5.1 Check the VSC valve sealing .................................................................................................. 27

3.5.2Check the VNR valve sealing.................................................................................................. 27

3.6 Self-control of monitoring PNP1 signal............................................................................................ 27

3.7 Control of the cycle of monitoring PNP1 signal............................................................................... 28