5

Safety and Warranty

plug cable disconnected from the power socket.

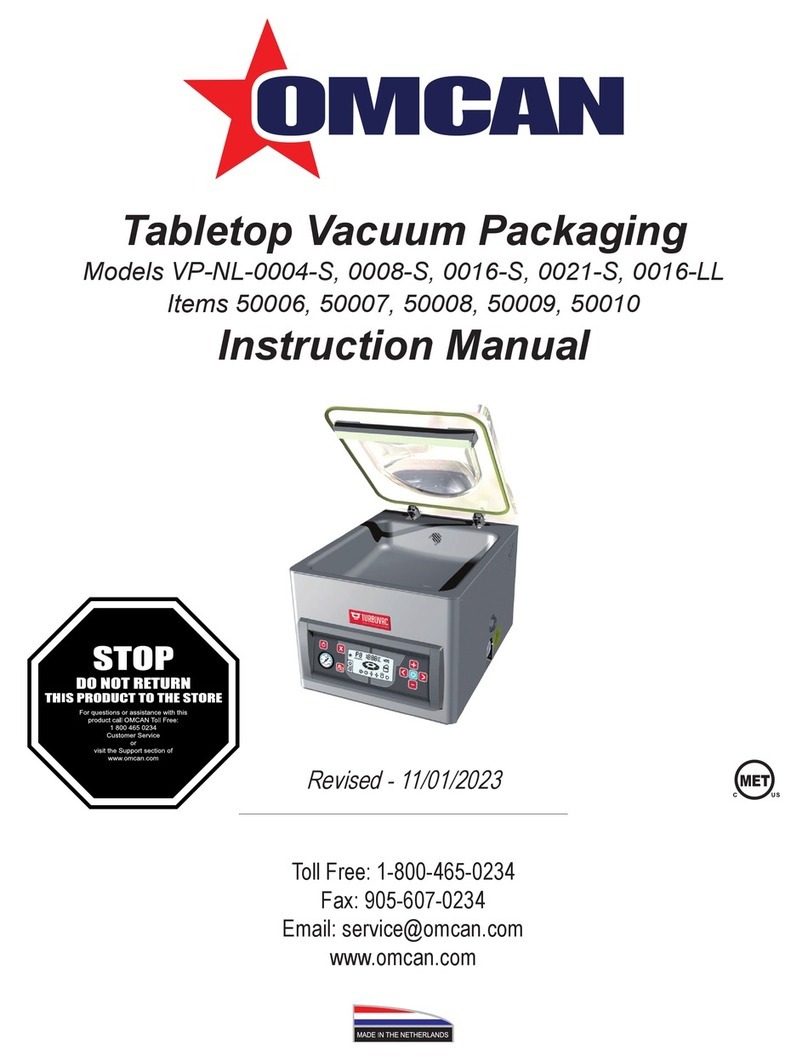

• Vacuum packing does not replace other preservation procedures, but can be used alongside them.

• Perishable foods however require refrigeration or freezing to avoid deterioration; vacuum packing

lengthens their preservation time and maintains their organoleptic qualities intact.

• The pre-packaged products must be in any case consumed with the expiry date indicated on the

packaging.

• A higher vacuum level indicates less presence of oxygen, and therefore the possibility of better

preservation.

• Liquids must be refrigerated before being packaged in vacuum pack bags to prevent them leaking or

suction in the vacuum chamber.

• Powder products and grains must be covered with a napkin before being vacuum packed to avoid them

being sucked into the vacuum chamber, which would obstruct the valve or damage the pump.

• Containers not suitable for vacuum packing preservation can implode due to the eect of the air pressure,

causing damage and injury; for freezer preservation, only use the specic tempered glass jars for freezers.

• The vacuum pump and the sealing system are equipped with thermal protection; in the event of

overheating, the machine automatically stops and can start working again only after a few minutes of

cooling.

• The automatic operating settings were created at the time of manufacture to obtain the best performance

of the machine, in terms of safety and reliability. If in particular cases, dierent performance is required to

those pre-set, you need to proceed in manual mode.

• If you don’t wait the minimum time required between the connection to the mains and the start of the work

cycle, you need to disconnect and re-insert the plug in the socket and wait the minimum time required (15

seconds).

• When using with containers it is recommended to use the appliance in manual mode and to pay close

attention to the heating of the sealing bar, to avoid burns.

• If worn, the cable should be replaced by a specialist technician with cable type HAR H05VV-F or however

equal to the cable supplied.

• Practice and experience will allow you to obtain the best results from the appliance with every dierent type

of food.

• For its use, pay attention the appliance is on a at and stable surface.

• To work, the appliance must be connected to a power socket that is always easily accessible during use.

• Acoustic level under 60 dBA.

• Minors must not play with the appliance.

• Cleaning and maintenance of the appliance must not be carried out by unsupervised minors.

INFORMATION ON VACUUM PACK PRESERVATION

VACUUM PACKING

It means removing the air from a container or bag, to preserve the content from harmful eects caused by

oxygen, such as oxidation or development of mould and bacteria. All the objects, in contact with the air, are

subject to alterations; these alterations are particularly obvious in food. The air and humidity in foodstus

cause mould and micro-organisms to develop, a loss of avour and smell and colour alterations. Preservations

systems, such as refrigeration, freezing and drying, have the purpose of reducing and preventing such

alterations; vacuum packing, thanks to air extraction, considerably lengthens the preservation period of the

foodstu whether fresh or preserved. To make the vacuum time ecient and lasting, the container and the bag