7

1

3

4

6

2

5

4

20....

TYPE

Modello

CODE

Codice

S/N

L/MIN

CFM

bar =

psi =

Tank =

RPM

kg =

dB(A)

V = Hz = A = kW = HP =

EN

SAFETY REGULATIONS

read this page carefully before carrying out any intervention on the compressor

TO DO:

Make sure that mains voltage corresponds to the voltage indicated on CE plate and that cable of suitable cross-section are

used for electric connections.

Always check oil level before starting the compressor.

Be familiar with emergency stop control and all other controls.

Unplug the connector before any maintenance work, so to avoid accidental start.

Ensure that all parts have been correctly reassembled after any maintenance work.

Keep children and animals off the working area to avoid injuries caused by devices connected to the compressor.

Ensure that temperature of the working environment ranges between +2 and + 45 ºC. Compressor working temperature shall

range between 70÷85°C (20-25°C room temperature). Lower temperatures may causes condensate accumulation inside the

oil separator tank (inside the compressor).

Check for condensate and if necessary, drain it (see maintenance).

The compressor should be installed and operated in a non-explosive environment.

Allow at least 80 cm between the compressor and the wall so to allow free air flow to the fan.

Press the emergency button on the control panel only in case of actual need so as to avoid possible damages to people or the

very compressor.

When calling for technical assistance and/or advice, always mention model, code and serial number indicated on CE plate.

Always follow the maintenance schedule specified in the user’s guide.

DO NOT:

Do not touch inner parts and pipes as they are very hot during compressor operation and stay hot for a certain time after

compressor stops.

Do not position inflammable close to and onto the compressor.

Do not move the compressor when the tank is under pressure.

Do not operate the compressor if the power cable is damaged or defective or if connection is unstable.

Do not operate the compressor in wet or dusty environments.

Never aim the air jet at people or animals.

Do not allow unauthorized people to operate the compressor and give them all required instructions.

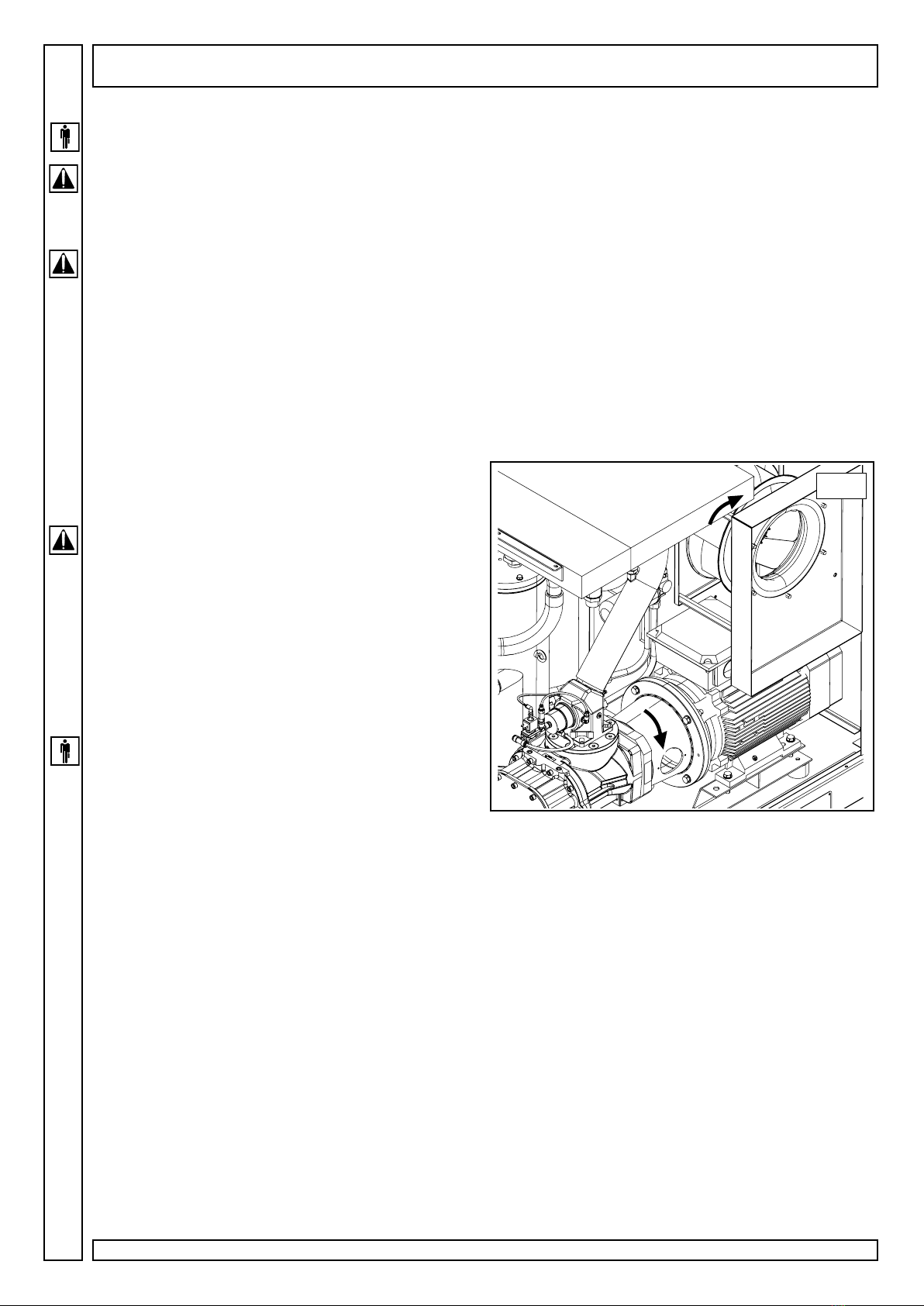

Do not hit fans with blunt objects as they might break during compressor operation.

Never operate the compressor without air filter.

Do not tamper with safety and adjusting devices.

Never operate the compressor when doors/panels are open or removed.

Do not strike the fans with contusive or metal objects as they could cause sudden breakage during functioning.

Do not allow the compressor to function without the filter and/or air pre-filter.

Do not tamper with safety and adjustment devices.

Never allow the compressor to function with the hatches/panels open or removed.

PRODUCT IDENTIFICATION

The compressor Your have purchased has its own CE plate showing the following data:

1. Manufacturer’s data.

2. Year of manufacture.

3. TYPE = name,

CODE = code,

SERIAL NO. = serial number (to be always mentioned when calling for technical assistance).

4. Tech data: air intake/air delivery, Max. operating pressure, Tank capcity , Rotations per minute, weight.

5. Voltage , frequency , absorption, power.

6. Noise level.

NOBEL DV 30-37 CSA - Cod.197EE0612ML - Rev.2 09/2019