OMEGA AUTOMATICS 2020 v3.0.2 2

Table of Contents

Installation procedure .............................................................................................................................................4

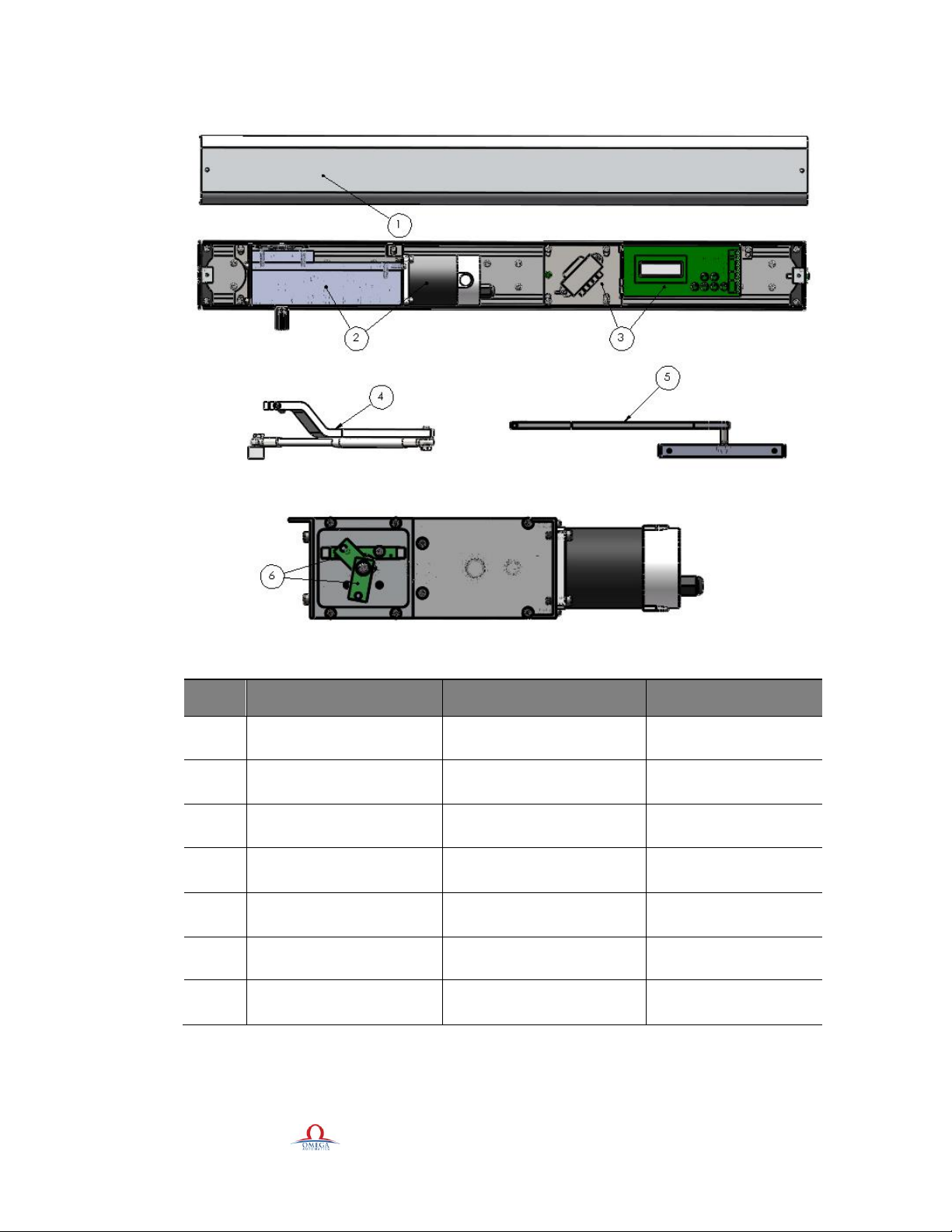

1. Replacement parts ...............................................................................................................................................5

2. General Information............................................................................................................................................6

2.1 Installation Instructions....................................................................................................................................6

2.2 Manual storage.................................................................................................................................................6

2.3 omegaautomatics.com website ........................................................................................................................6

2.4 Dimensions .....................................................................................................................................................6

2.5 Building codes and standards ..........................................................................................................................6

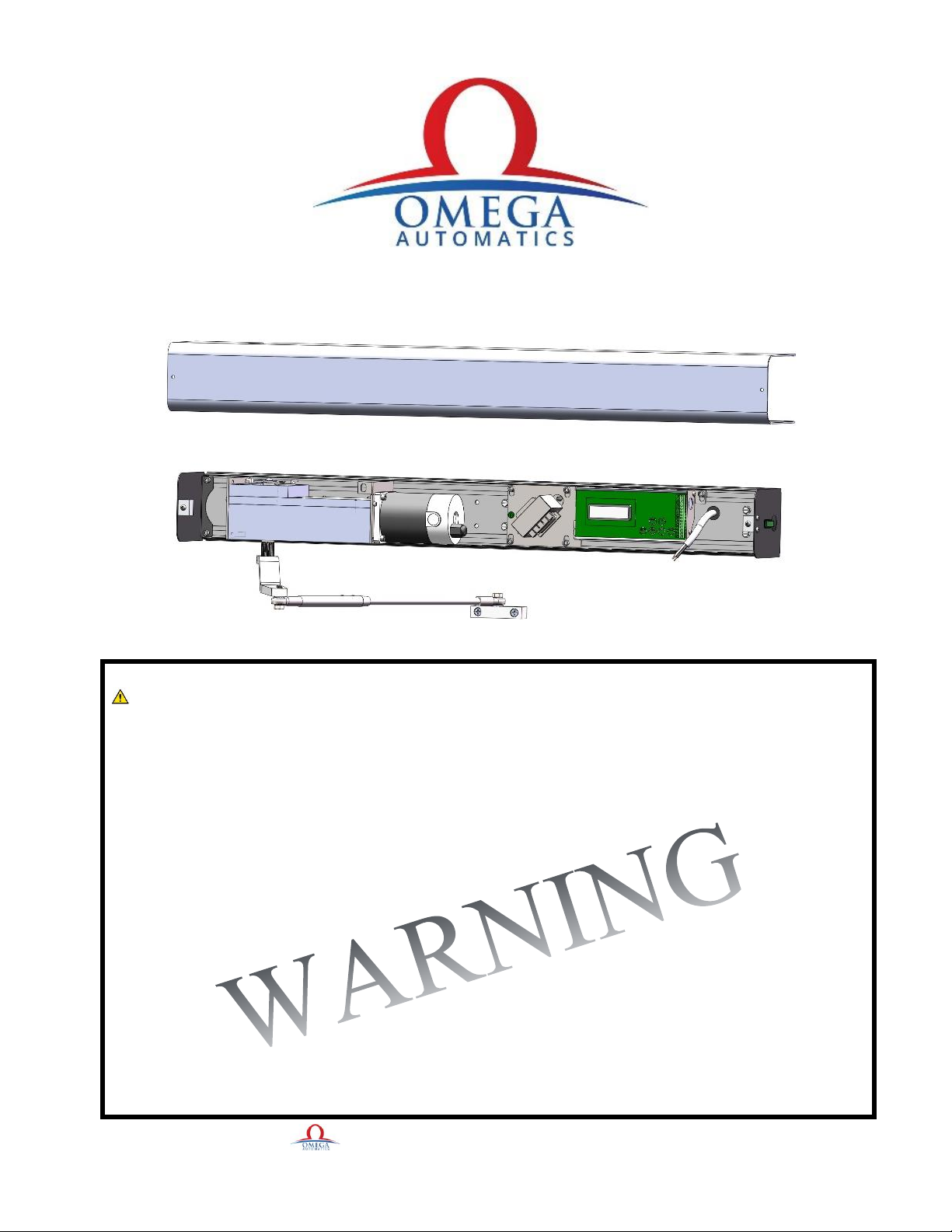

3. Product description..............................................................................................................................................6

3.1 Intended use.....................................................................................................................................................6

3.2 Maximum deck weights...................................................................................................................................6

3.3 Hardware as shipped........................................................................................................................................7

3.3.1 Single swing door ..................................................................................................................................7

3.3.2 Double swing door ................................................................................................................................7

4. Safety information ...............................................................................................................................................7

4.1 Safety Instructions............................................................................................................................................7

4.2 Safety warnings................................................................................................................................................7

4.3 Residual hazard................................................................................................................................................8

5. Recommended tools.............................................................................................................................................8

6. Standard torque ranges.......................................................................................................................................8

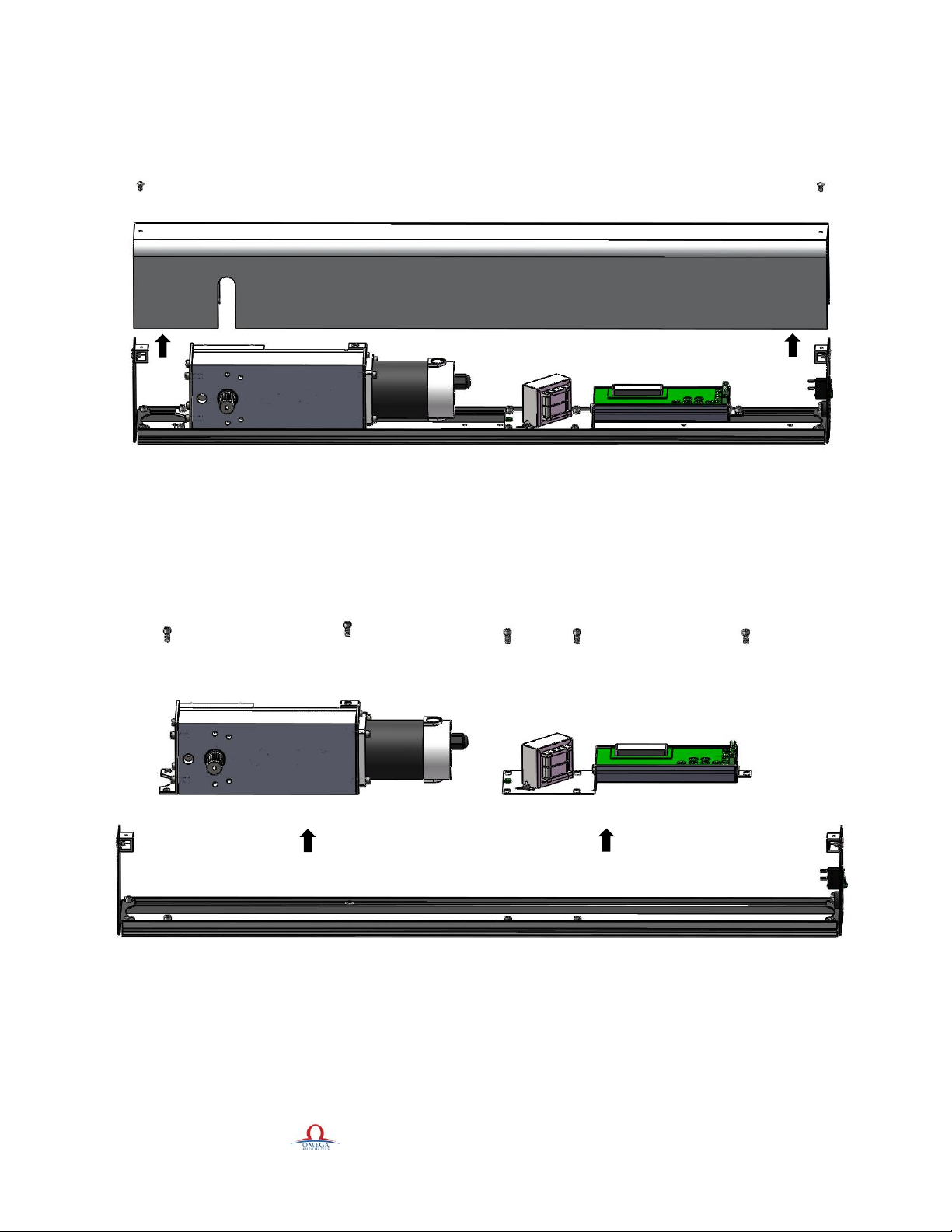

7. OAL-100 installation process..............................................................................................................................9

7.1 Unpack the box and take out cover..................................................................................................................9

7.2 Installation of bottom track on the wall...........................................................................................................9

7.3 Motor and control board wiring ....................................................................................................................10

7.4 Arm installation ............................................................................................................................................11

7.4.1 Push arm application ............................................................................................................................11

7.4.2 Pull arm application .............................................................................................................................13

7.5 Programming (Basic).....................................................................................................................................14

7.6 Programming Heavy Duty (XP) operators.....................................................................................................18

8. Trouble shooting................................................................................................................................................19