3

EVENT inputs/ CT function (optional) 1 0: None, 1: Event Input3, 2: RS-485 Communication

EVENT inputs/ CT function (optional) 2 0: None, 1: Event Input2, 2: CT measure input2.

EVENT inputs/ CT function (optional) 3 0: None, 1: Event Input1, 2: CT measure input1.

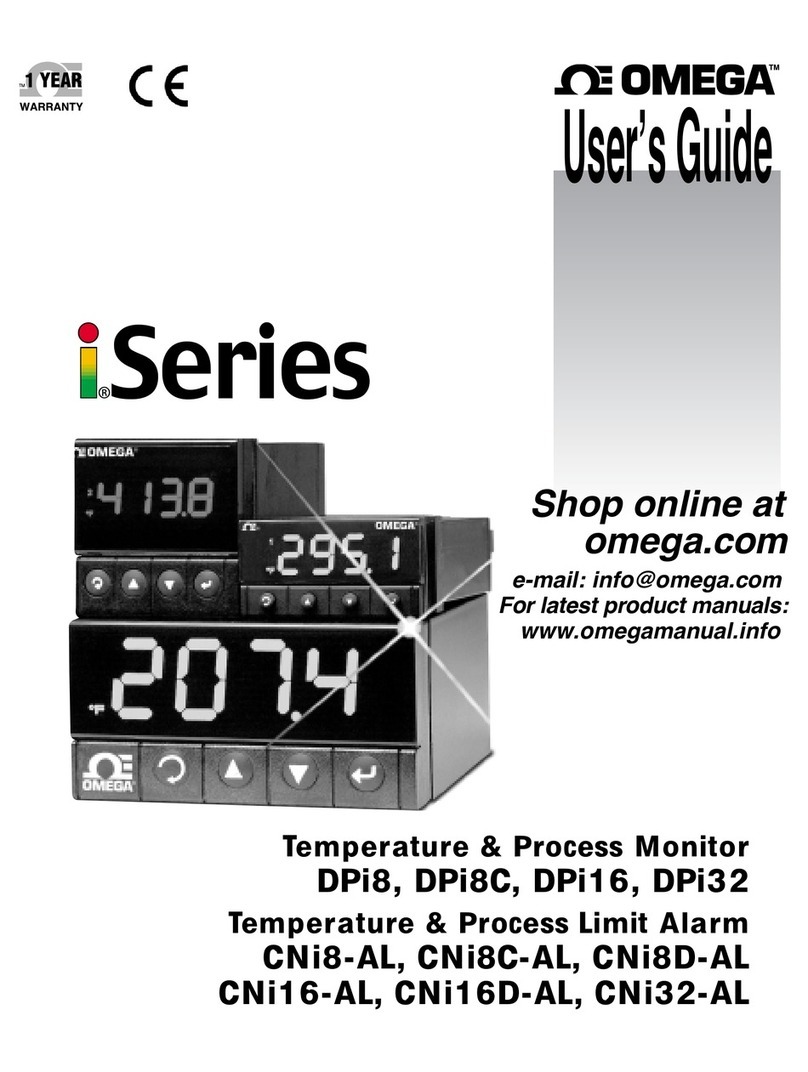

Specifications

Input Voltage 80 ~ 260Vac 50/60Hz; 24Vac 50/60Hz ±10%; 24 Vdc ±10%

Power Consumption 8VA max.

Display Method LCD display. Process value (PV): Yellow color, Set point (SV): Green color

Sensor Type

Thermocouple: K, J, T, E, N, R, S, B, L, U, TXK

(Thermal couple measuring location are not intended to be directly connected to the MAINS supply.)

3-wire Platinum RTD: Pt100, JPt100

Resistance: Cu50, Ni120

Analog input: 0 ~ 5Vdc, 0 ~ 10Vdc, 0 ~ 20mA, 4 ~ 20mA, 0 ~ 50mVdc

Control Mode PID, PID program control (Ramp/Soak control), FUZZY, Self-tuning, Manual and On/FF

Control Output

Relay output: Max. load 250Vac, 5A resistive load

Voltage pulse output: 12Vdc, Max. output current 40mA

Current output: DC 4 ~ 20m A output (Load resistance: Max. 500Ω)

Analog voltage output: 0 ~ 10Vdc

Alarm Output Type Relay output: Max. load 250Vac, 3A resistive load

Display Accuracy 0 or 1 digit to the right of the decimal point (selectable)

Sampling Rate Analog input: 0.1 sec/ per scan; Thermocouple or Platinum RTD: 0.1 sec/per scan

Vibration Resistance 10 to 55Hz, 10m/s2 for 10min, each in X, Y and Z directions

Shock Resistance Max. 300m/ s2, 3 times in each 3 axes, 6 directions

Ambient Temperature 0°C ~ +50°C

Storage Temperature -20°C ~ +65°C

Altitude Max. 2000m

Relative Humidity 35% ~ 80% RH(non-condensing)

Operation

There are three modes of operation: operation, regulation and initial setting. When power is applied, controller gets into the operation

mode. Press the key to switch to regulation mode. If the key is pressed for more than 3 seconds, controller will switch to the

initial setting mode. Pressing the key while in the regulation mode or initial setting mode, forces the controller to return to the

operation mode..

PV/SV: Sets the temperature set point and displays the temperature process value. Use keys to set the temperature set

point.

Setting method: While in any function mode, press the key to select the desired function and use keys to change

settings. Press key to save the changes.

The flow chart below shows how to switch the settings and internal functions:

Regulation Mode Operation Mode Initial Setting Mode

Press key less than 3 sec

Press key

Press key more than 3 sec

Press key

【Operation Mode】Parameter Setting:

Display Description Factory Setting

Use to set temperature set point, use to switch between the display parameter

RUN/STOP: Control setting RUN or STOP RUN

PATTERN: Start pattern setting (set control mode to PROG mode) 0

STEP: Start step setting (set control mode to PROG mode) 0

SELECT POINT: Decimal point setting (0: integral ; 1: one decimal point) 1

LOCK: Setting lock mode (LOCK1: all; LOCK2: onlySV and F1/F2 key is allowed) OFF

ALARM1 HIGH: Upper limit alarm 1 (display according to the setting in ALARM mode) 4.0

ALARM1 LOW: Lower limit alarm 1 (display according to the setting in ALARM mode) 4.0