THE RHINOBOND SYSTEM WARRANTY

Guaranteed for 200,000 cycles of operation, or three years from date of purchase,

whichever comes first. During this period OMG, Inc., at its option, will repair or replace

any tool for the roofing contractor who originally purchased the tool. This will be done

free of charge, provided the tool is determined defective in materials or workmanship

upon examination by an Authorized RhinoBond System Service Technician.

This Warranty will be honored only if:

A. No evidence of abuse, misuse or failure to follow safety or operating instructions, or

improper modification of the tool, is present. (Read this Owner’s Manual for safe use

and proper operating instructions.)

B. When replacement is necessary, the first end-user returns the tool with transportation

prepaid, to the nearest Authorized RhinoBond System Service Technician with

purchase receipt or other positive proof of purchase.

C. Only genuine RhinoBond tool, fasteners, and plates are used in the application.

THE FOREGOING WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES. ALL OTHER

WARRANTIES, WHETHER ORAL, WRITTEN, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE SHALL NOT APPLY. THESE OTHER EXPRESS OR IMPLIED WARRANTIES

ARE SPECIFICALLY EXCLUDED. BUYER’S OR USER’S REMEDIES ARE SOLELY AND EXCLUSIVELY

AS STATED HEREIN. OMG, INC. SHALL IN NO EVENT BE LIABLE FOR INCIDENTAL,

CONSEQUENTIAL, INDIRECT OR SPECIAL DAMAGES RESULTING FROM FAILURE OF THIS

WARRANTY. IN NO EVENT, WHETHER AS A RESULT OF BREACH OF CONTRACT, WARRANTY,

TORT (INCLUDING NEGLIGENCE) OR OTHERWISE, SHALL OMG, INC.’S LIABILITY TO THE

BUYER OR USER OF THE TOOL OR ANY LOSS OR DAMAGE ARISING OUT OF THE BREACH

OF WARRANTY, CONTRACT OR TORT, EXCEED THE PURCHASE PRICE HEREIN. ANY CLAIM

OR LIABILITY SHALL IN ANY EVENT TERMINATE UPON THE EXPIRATION OF THE WARRANTY

PERIOD SPECIFIED ABOVE.

INTRODUCING THE RHINOBOND®SYSTEM

Congratulations! The RhinoBond System is one of the industry’s most advanced fastening systems for

installing thermoplastic membrane roofing and, in Europe only, “approved” clean EPDM membrane*.

RhinoBond is a portable, easy-to-use, system that secures membrane to roofing substrates using micropro-

cessor-controlled induction welding.

Roofing installed this way has several benefits:

• Fewer Fasteners -- RhinoBond requires 25-50% fewer fasteners vs. mechanical attachment to meet FM

1-90 and Eurocode National wind uplift requirements.

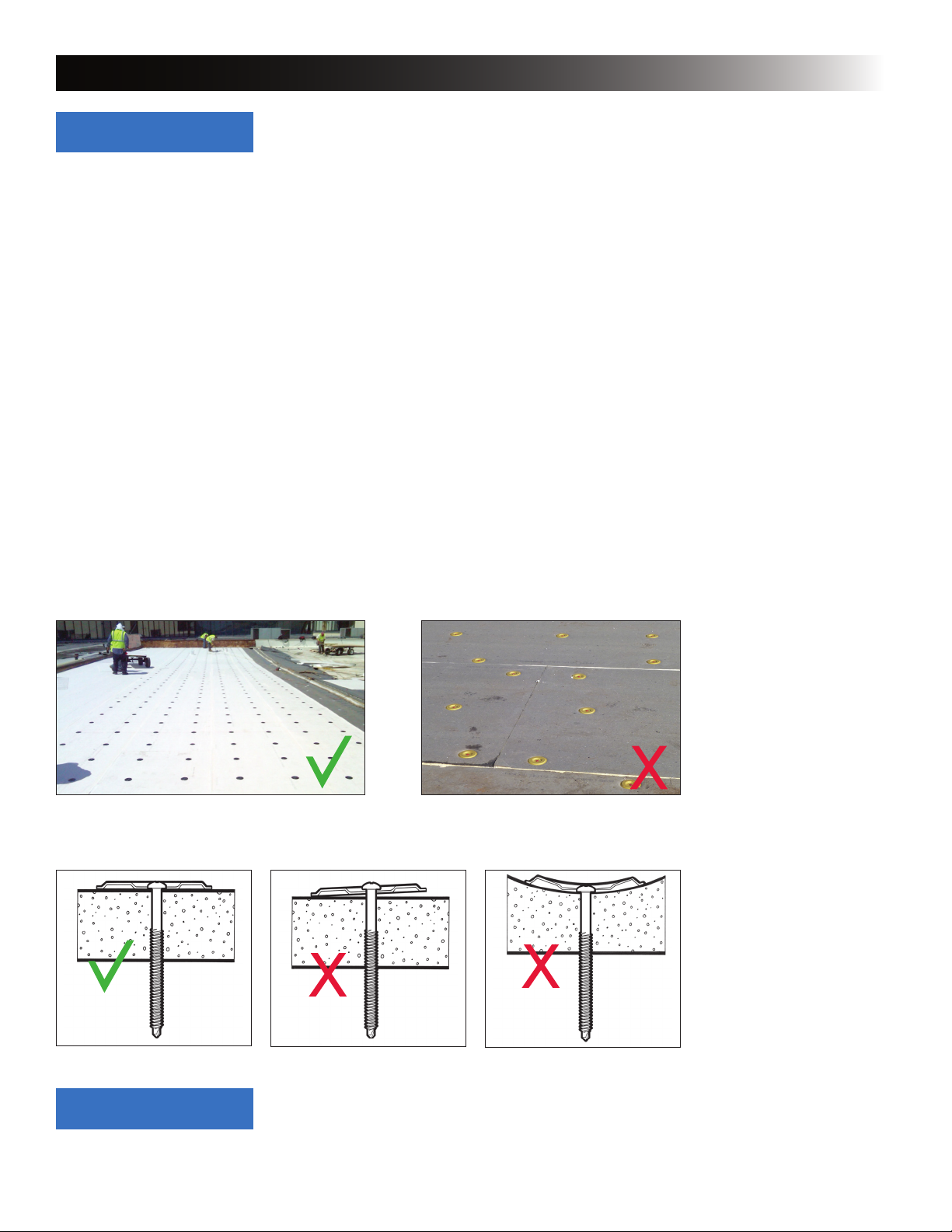

• Zero Penetrations – The fasteners and plates used are all installed under the membrane, so with

RhinoBond there are no membrane penetrations or potential points of entry for moisture.

• Less Seaming – RhinoBond does not require any half-sheets, just full width membrane everywhere. This

can eliminate up to 30% of the seams when compared to a traditional mechanically attached system.

• Superior Wind Performance – The RhinoBond System has higher wind uplift resistance with fewer

fasteners and fewer seams when compared to mechanically attached roofs.

The RhinoBond system uses powerful induction technology to create a strong bond between the roofing

membrane and fastening plates. The technology that makes this possible, SINCH®Technology, is a compact

microprocessor-controlled electromagnetic induction bonding process. Today, this rugged technology is being

used to revolutionize industrial and consumer applications.

While RhinoBond is a safe, tested tool, we caution you to be sure that every member of your crew has a

thorough understanding of the RhinoBond System before attempting to use it. Read, understand and follow

all instructions.

Congratulations on your new purchase. We look forward to your feedback. Please send us your

comments and suggestions at any time.

RhinoBond Team

800.633.3800 | 413.789.0252 | www.rhinobond.com

*Clean EPDM Membrane -- currently there are a limited number of clean EPDM options available only in Europe and approved for

use with RhinoBond. Always verify membrane suitability and approvals with membrane supplier. RhinoBond is not suitable for use

with other EPDM membrane.

© Copyright 2020 OMG, Inc. All rights reserved.

RhinoBond®and SINCH Technology®are registered trademarks, OptiWeld™ is a trademark of OMG, Inc., a leading provider of

innovative fastening solutions and products for the construction industry.

PATENT NOTICE: U.S. Patent Nos. 6,710,314; 6,849,837; 7,399,949; 8,492,683; 8,933,379; 10,925,124.

Canadian Patent Nos. 2,458,353; 2,602,753.

Contact OMG Roofing Products or your roofing membrane manufacturer for the most current list of approvals.

TABLE OF CONTENTS

2 Table of Contents

Introducing the RhinoBond System

The RhinoBond System Warranty

3 Safety Instructions

5 Intended Use

Power Requirements

6 System Description

7 Safe Start UP and Shut Down

8 Tool Operation

Touch Screen Calibration

Select Language

9 Automatic Calibration

11 Manual Calibration

13 Menu Settings & Help

16 EC Declaration of Conformity

RhinoBond Owner’s Manual - Page 2