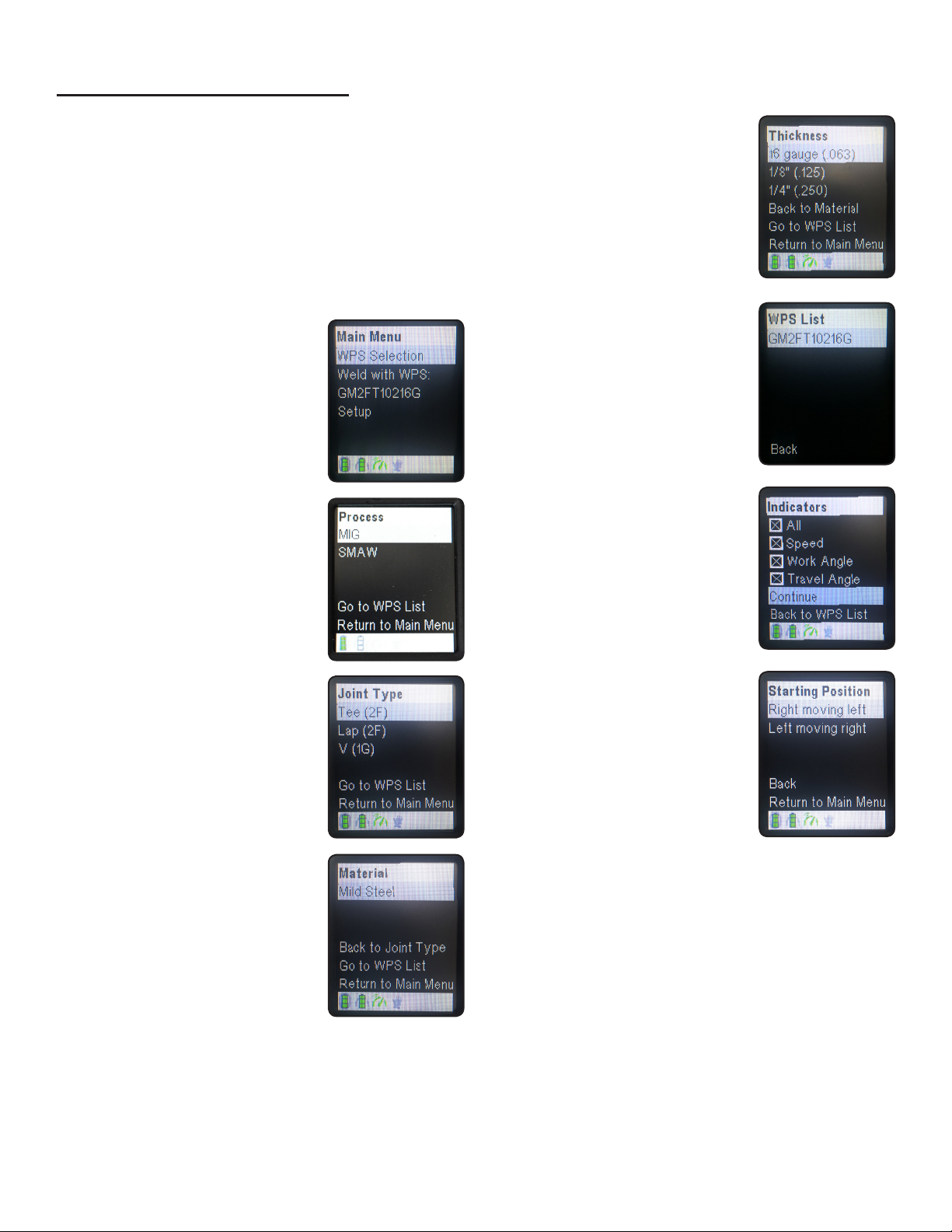

7RealCareer® Welding Solutions – guideWELD® LIVE real welding guidance system

Available Default WPS

guideWELD® LIVE welding guidance system has 18 default WPS capability to weld for the

tee joint, lap joint, and v-groove joint. The tee joint is in a 2F position, lap joint is in the 2F

position, and the v-groove joint is in the 1G position. All base material is mild steel with

several material thicknesses available in MIG and Stick.

Default MIG WPS

Default Stick WPS

WPS

Number

Material

Thickness

Welding

Position

Joint

Design

Consumable

Type

Electrode

Size

Amp

Range

Welding

Work Angle

Welding

Travel Angle

Welding

Travel Speed

(inch) (AWS Wire Class) (inch) (amps) (Range of Degree) (Range of Degrees) (ipm)

TARGET TARGET TARGET TARGET

SM2FT1351/8 1/8 2F Tee E7018 1/8 120 45 20 11

SM2FL1351/8 1/8 2F Lap E7018 1/8 120 45 20 11

SM1GG1351/8 1/8 1G V-Groove E7018 1/8 120 90 20 11

SM2FT1401/4 1/4 2F Tee E6013 1/8 95 45 20 7

SM2FL1401/4 1/4 2F Lap E6013 1/8 95 45 20 7

SM1GG1401/4 1/4 1G V-Groove E6013 1/8 95 90 20 7

SM2FT1303/8 3/8 2F Tee E6010 1/8 90 45 20 6

SM2FL1303/8 3/8 2F Lap E6010 1/8 90 45 20 6

SM1GG1303/8 3/8 1G V-Groove E6010 1/8 90 90 20 6

Base Material (type): All StickWPS’s are tested with STEEL

Welding Polarity: DC

Mode of Wire Transfer: All WPS’s for SMAW process

Measurement Units: All WPS’s are available in Metric and Imperial.

NOTE: Customizable WPS available

WPS

Number

Material

Thickness

Welding

Position

Joint

Design

Specied

Weld Size

Volt

Range

Wire Feed

Speed

Welding

Work Angle

Welding

Travel Angle

Welding

Travel Speed

(T1, T2) (AWS A2.4) (volts) (WFS) (Range of Degree) (Range of Degrees) (Minimum ipm)

TARGET TARGET TARGET TARGET TARGET

GM2FT10216G 16-18ga 2F Tee 0.09 17 180 45 10 14.7

GM2FL10216G 16-18ga 2F Lap 0.06 17 180 45 10 16.2

GM1GG8216G 16-18ga 1G V-Groove 0.06 17 145 90 10 13.7

GM2FT1401/8 0.125 2F Tee 0.125 18 270 45 10 13.2

GM2FL1281/8 0.125 2F Lap 0.125 17.5 265 45 5 14.7

GM1GG1271/8 0.125 1G V-Groove 0.125 18 230 90 10 13.2

GM2FT1701/4 0.25 2F Tee 0.25 23 360 45 5 8.5

GM2FL1701/4 0.25 2F Lap 0.25 23 360 45 5 10.0

GM1GG1461/4 0.25 1G V-Groove 0.125 22.5 340 90 10 7.7

Base Material (type): All MIGWPS’s are tested with STEEL

Welding Polarity: DC

Filler Metal Size (diam.): AllWPS’s are tested with 0.035

Mode of Wire Transfer: All WPS’s for GMAW process

Filler Metal Type (AWS classication): AllWPS’s are ER70S wire

Measurement Units: All WPS’s are available in Metric and Imperial.

NOTE: Customizable WPS available