3

General Safety Instructions

Danger!

1. Correct use

OML clamping systems work safely and troublefree, if

they are used according to their specification i.e. to clamp

components on machine tools. Any other use can cause

hazards. For any damages resulting herefrom OML is not

responsible.

Danger to the

environment!

General precept sign!

Follow the instructions!

General warning sign!

Warning of risk of

crushing!

Warning of hand injuries!

Warning of suspended

load!

2. Demands on operators

This OML product must be installed, operated and maintai-

ned only by qualifi ed and regularly trained personnel.

4. Transport

Please use suitable lifting gear for product heavier than

16 kg!

5. Safety Precautions

• Maintenance and actuation must be carried out at

stopped machine only.

• Maintenance and set up work must be carried out in

safe areas only.

• During installing, connecting, adjusting, runoff and

testing, it must be ensured, that no accidential actuation

of the clamping unit can be carried out by the worker or

any other persons.

6. Max. speed

The clamping unit is intended for stationary use only, and

must not be used under rotation!

7. Danger of injury

• Danger of injury because of missing accessories.

• When actuating the clamping system there is increased

chrushing hazzard due to the stroke of the moving

components of the clamping system.

• Never reach for the clamping system while the spindle

of machine is rotating.

• Prior to working at the clamping system, make sure, that

the spindle of the machine cannot be started.

• Work pieces that are clamped with too low clamping

pressure, can be ejected!

• Excessive clamping pressure can cause damage or

breakage of the individual components of teh cklamping

system. Work pieces can be released.

3. Visual inspection

Please check the product for visible damage prior to use!

8. Clamping force

The clamping force of the clamping system can vary, de-

pending on its condition (lubrication and contamination).

The clamping forces have to verifi ed in regular intervals.

Use suitable staic grip force gages.

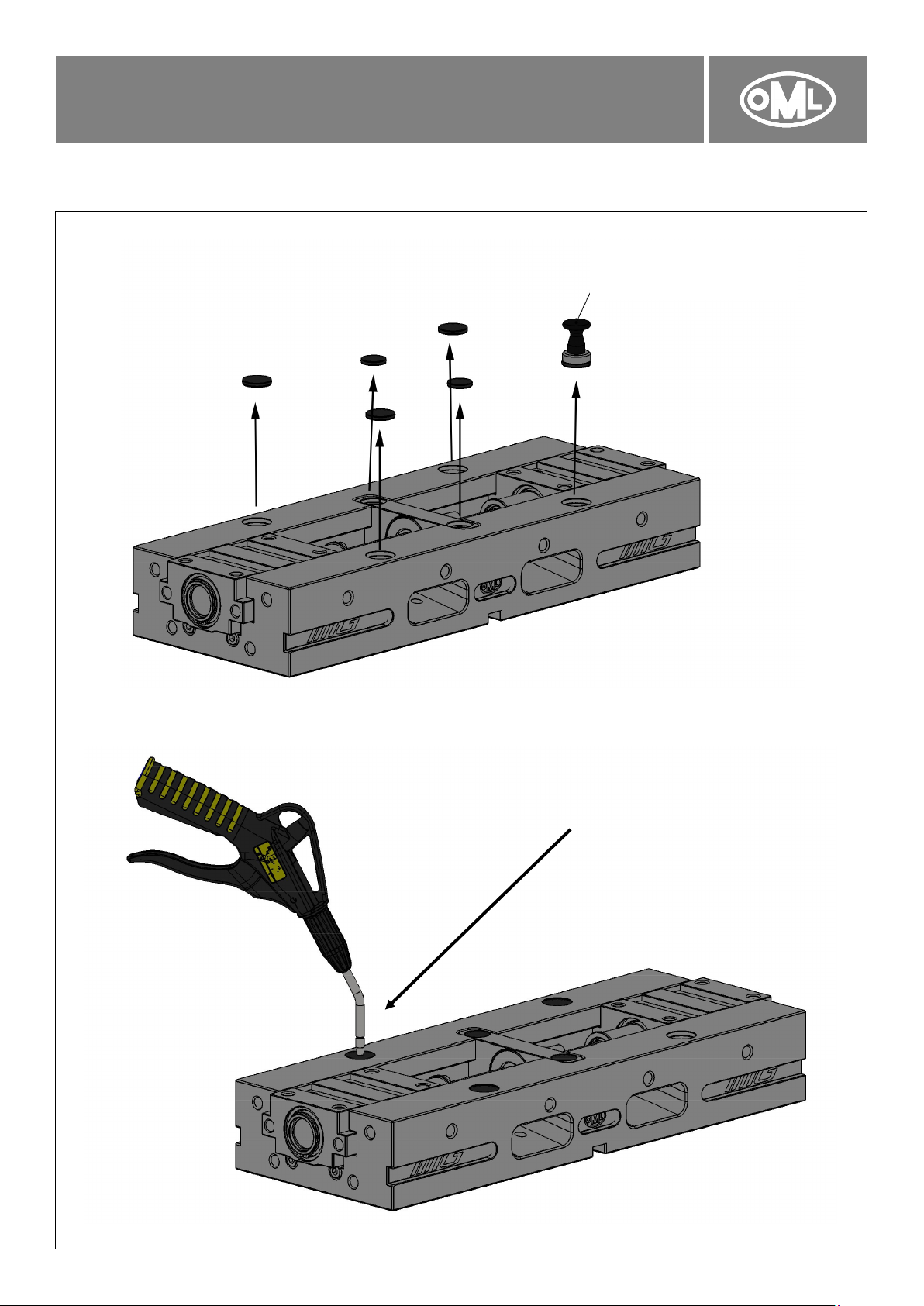

9. Maintenance

The stationary clamping system has to be maintained in

regular intervals. Check the condition by measuring the grip

force with a grip force gage. Maintenance must be carried

out at stopped machine only.

Replace damaged parts with original OML spare parts only.

Maintenance must be carried out at stopped machine only!

Insuffi cient and improper maintenace voids any warranty

from OML.

10. Environment protection

Danger for environment when handling incorrect! Incorrect

handling of environment hazardous materials, especially

the disposal, may result in environmental damage.

• Always follow below instructions.

• In case environmentally hazardous material

polluted the environment always take suitable ac-

tions immediately. If in doubt, inform the local

authority about the pollution.

The following hazardous materials are used: Lubricants

such as oil and grease can contain poisonous agents. They

must not pollute the environment. The disposal must be

carried out by a suitable waste management company.

For a proper function of the work holding, use original OML

lubricant only.

For any problems or questions please contact

OML directly or one of our authorized offices.

ALL REGULATIONS ACCORDING TO THE PREVIOUS

POINTS MSUT BE OBSERVED. THE USE ON MACHINE

TOOLS HOWEVER, ALWAYS CAUSES SOME RESIDUAL

RISKS, THAT HAVE TO BE ELIMINATED BY THE USER BY

SUITABLE SAFETY ACTIONS.